All Activity

- Past hour

-

The whatever-kinda-goo that gets up in the frame has to go somewhere , so the crankcase is best option. If you have ever owned a Ducati single you know what their after the fact breather system looked like .

-

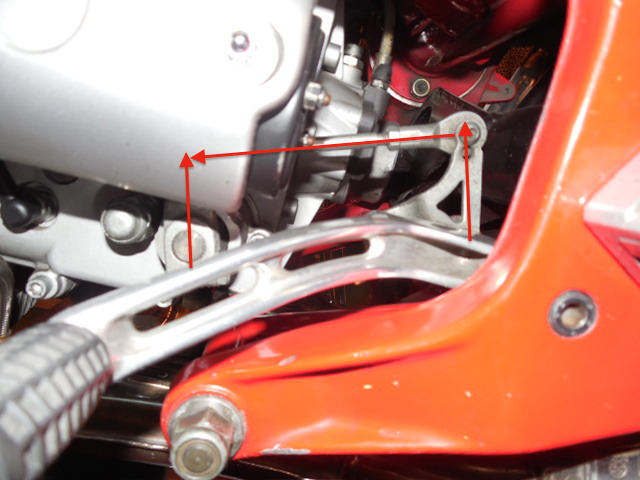

I got my parts from Midwest Control Products in Bushnell , Il. . www.midwestcontroproductsl.com TR6-150 threaded rod. DNTFL-6 rod end , DMCS-6 ball joint , DNTFL-6 ball joint , DMCSL-6 ball joint. I will never understand why they installed two r.h. thread rod ends on an adjustable rod. I di turn this quite a long time before I realized I was going nowhere ! Hmmm IDK why I went crazy on the rod ends but I got all of them and picked the ones I liked. On the threaded rod , just get two and cut the first one the same length as the original , reassemble and adjust to suit you. You have the extra rod to work with ! This stuff is inexpensive and top quality. You will not regret doing this. This was from Aug/2011 so I hope these part #s are good. These people manufacture high performance things so this is not a hokey-pokey place. Good luck

- Yesterday

-

Well , you need to purchase a l.h.thread ball end and a threaded rod w/l.h. &r.h. thread and go to work. I will try to find some part #s. This is the best way to fix this so you can trim this height to suit you .

-

There are a couple options by changing the shift mechanism. You can lengthen the connecting rod or rotate the pawl arm on the gearbox one tooth clockwise (which will likely necessitate changing the rod length to keep the arms parallel). This may require some 'fettling" to make both you and the gearbox happy . . .

-

mikev started following shift lever height

-

Hi, I got some new boots and the toe is thicker than my old pair, so its a bit of a strain to shift up. I'd like to raise the shift pedal upwards a bit but didn't see anything in the manual on how to accomplish this. Did not want to start mucking around with the shifter till I asked here. Thanks in advance for any advice. Mike

-

Well not really because they even drive around with the window down on days that don't require A/C and in very late model cars. If they were all driving old beaters I may take your point. Phil

-

I'm a bit loath to say it mate, but that is more or less exactly what Resolve is. I'm not even sure there are all that many other products out there. To be honest, I don't do very much editing at all. Even so, my experience is, "simple" products are generally crap. To get good results, you need a good product. The trick is to concentrate on the features you want to use, learn them, and ignore the rest.

-

EEEeeeeyeah... No That's exactly the sort of thing I *don't* want. Though obviously it's the bee's knees for 'professionals' it's WAY to competent and thus overcomplicated for me. Not to mention that my 'friendly use' computer is a 15 year old Alienware R2 running Win7. Dammit I'm a mechanic, Jim, not a Doctor. I'm imagining something that looks like an upper and lower screen; the upper with a video and slider, the lower with audio and a slider. Drag and drop one onto the other. Of course there needs to be easy-to-use sectioning tools for both, to create multiple clips and then reassemble them into a single combined product. It's probably out there, but I'm not motivated to download and test and reject a bunch of software suites to find one that is easy to use and adequately competent.

-

The point with the external mic is the critical one. The audio recording quality on a GoPro is fine (we've got two of them at work too...), as is the quality on a Zoom recorder and co. . The point is collecting good audio to record. The short answer to that: use good mics and do it right. The GoPros we have are these, I think https://gopro.com/en/us/shop/cameras/hero10-black/CHDHX-101-master.html further equipped with these https://gopro.com/en/us/shop/mounts-accessories/camera-media-mod/ADFMD-001.html The media mod does have an audio input. It is only a 3.5mm mini jack, but better than nothing. PS: that is not to be construed as a recommendation for GoPro. I've barely used the things. It's just an indication of what is possible. If GoPro have something like that, I dare say competitiors will too.

-

Although I (still) don't know how to use this, I'll throw it into the ring. We have it at work, and the colleague that uses it most seems to like it. Another colleague, only been there 2 years or so, did a Masters in Documentary Film Production. I gather she learned to use it whilst at Uni, so it's not just us using it. There is a free version, but I don't know what the difference between the free and the sold version is. Even so, the sold version apparently only costs about $300,-. Have a look at it. Maybe it is a solution. https://www.blackmagicdesign.com/products/davinciresolve The blurb: One thing: the computer needs a bit of power, or it will be really, really slow. PS: I gather that the software is cheap because Davinci earns its money on cameras and such, and things like specialised controllers for the program. The want people using the software to keep them in the "ecosystem", so it is fairly cheap for the small-time user.

-

Book it up to environmental protection. The air that comes out of the crankcase is heavy with oil vapour. It's better for the environment if the re-condensed oil goes back into the motor.

-

@audiomickI'm very clear on why the pressure needs to be handled, just don't understand why a line that is connected directly to the sump has to be part of it. My older Ducatis just had a black rubber hose that came from the top of the crankcase and was strapped to the frame under the seat. Maybe that system is ancient now, but it worked very simply. Why the oil line is part of this system now is what I question. I'll stop beating a dead horse.

-

It would be a bit pointless if it were a closed system. It is there to compensate for the change in volume in the crankcase as the pistons go up and down. This change in volume is not all that far short of the displacement of the engine. A closed system would increase the total crankcase volume, thereby reducing the relative change in volume, but would not be able to compensate for the change. For that, air has to be able to escape on the downstroke, and get back in on the upstroke.

-

those are correct, but I have plates and pins in the mail that should be the correct ones. We'll see.

-

I have two pins 20mm on the thread dia. , 17mm on the pivot pin and one nut w/the hex being 30mm on the o.d. of the hex

-

Sure was. Dry as a bone now.

-

Well, I had never dug into where those expansion chambers came about. All I know, is that I had a Gitane Testi when I was 14 years old, and I purchased the expansion chamber sold by Motori Minarelli for my 49.9cc engine. I knew the reason and the principle about it, but I never imagined it came from Germany.

-

@activpop, was your leak at the washer, #20, in that diagram?

-

I've only replaced my vent hose once, but it really wasn't the source of my leak problems. Part of my issues was the #15 gasket for the oil pipe that the hose attaches to. (Notably, oil leak from this gasket appears at the 'weep hole" at the bottom of the clutch housing.)

-

Interesting. So it is not truly a closed system, it has an open line to the airbox. So when the engine is running, especially at higher rpms, there is negative pressure pulling out of the spine. So I'm not sure if that helps or hurts this condition of possibly getting oil contaminated, simply because there is an oil line open to the spine. Does oil ever get pulled up there? IDK. I'm no engineer. All this looking around though has me finding a crack in the rubber tube coming up from the engine. Time to visit the old thread on replacing it. How many tubes have you replaced on your high mileage Sport @docc?

-

Could have stuck to history without the political commentary, but fundamentally good. Oh, and "The engines are identical" is at best misleading, and at worst, well, misrepresentation. Anybody who's ridden one knows it's not 170 horsepower, doesn't come on like a light switch- in fact, the powerband is much less abrupt than a Kawasaki Triple. Even if every part number in the engine is the same, the pipes and the porting make all the meaningful difference. On most 2-strokes, an hour by a professional and a tailored pipe can add 10-50% to any 2-stroke, depending on era and state of tune.

-

One of the difficulties assessing the system is that the vapor recovery (which would include water vapor) is not on the parts diagram for the ventilation system ("oil pump"), but on the "air filter" page (16-20) . . .

-

This is correct, crankcase ventilation/oil vapor travel up from the back of the engine through the nefarious double-bend rubber hose under the frame to the bottom of the frame spine behind the headstock. The frame cavity acts as a separator with the gaseous fraction following the path @gstallons describes (a hose visible from the fitting on top of the frame spine, behind the headstock/ in front of the tank) to the airbox, and the liquid fraction draining down through the frame cavity to the return line and back into the sump. Ideally, adequate running temperatures will evaporate the water before it drains back into the sump. Less than ideal would be short operating times, very wet environs, and long storage periods. Also, oil selection plays a part. Pure synthetics (true ester base oils) have close to zero evaporation loss from heat and aid the efficiency of a complex, closed loop, crankcase ventilation system like ours.

-

Hence my previous concern about a risk of contaminating the oil. It seems like it is a closed loop system, where the give and take changes in pressure take place in a rectangular steel tube. Am I seeing this right?