Leaderboard

Popular Content

Showing content with the highest reputation on 03/16/2020 in all areas

-

Imagine some previous owner is removing the battery; he starts undoing the +ve terminal first. Then the spanner slips and touches the ECU. 12v goes to ground through that little wire. Sparks or melting wires get your attention. Don't ask how I know.3 points

-

3 points

-

Hi Kelly, valve play and timing have no connection. I've never measured AFR with a mistral crossover and oval exhaust. My setup is standard crossover and TI exhaust (which flows significantly better than the stock exhaust, but is quite loud) Again using a picture from Motoguzznix's file for visualization, the timing is dependent on the camshaft. It's best practice to adjust the point at which the intake and exhaust valve have the same lift to 2-3° before TDC and not at TDC. Or even behind, which is the reality in Guzzi engines after some time because the chain has worn a bit. The main issue with the V11 valve train are the guides, you will typical see a much larger play than factory specs after some time. So, changing the valve play versus the 0.25mm I've used will impact AFR and not timing or wear and tear. Disregarding all other factors, decreasing the play would reduce the airflow, which would lead to a richer mixture than I intended. Increasing it, within reason, would slightly improve airflow and lead to a leaner mixture. But as I wrote previously, the V11 camshaft is a good one, stay with 0.25mm. Cheers Meinolf2 points

-

Hi, I'm being quoted as recommending a valve play of 0,3mm or larger for both exhaust and intake valves on the V11. I can't recall recommending this for the V11. The V11 camshaft is very good and the ramps are not overly long. Using 0.25/0.25mm is my recommendation. The old Tonti camshafts, on the other hand, are best served with a valve play of 0.35/0.35mm. The have very long ramps, using the factory recommendation of 0.25/20mm leads to a opening angle of >400°, the valves are slightly (1-2/100mm) open over a wide range during ramp up. The effects are decreased valve cooling time, loss of mean pressure and cylinder fillling. The two pictures (Copyright Motoguzznix) show the effect for the 2 camshaft types. Cheers Meinolf2 points

-

Yes and you negate the lifting ramps on the cams which gives the followers and retainers a hard life. Ciao2 points

-

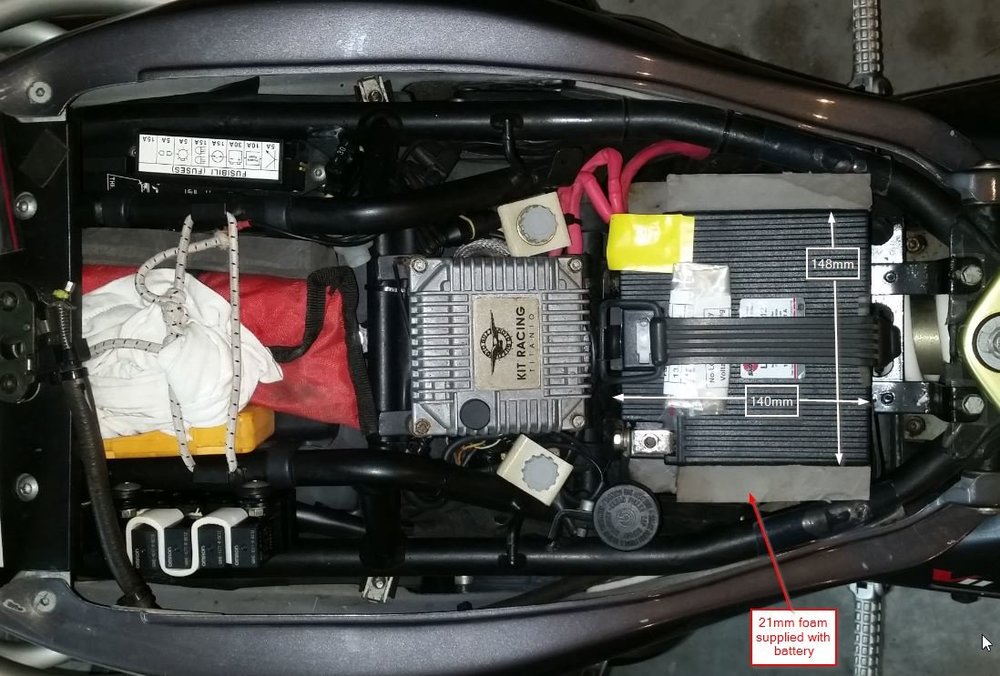

Hi, Well, I got off easy with my burned wiring. I began cutting open the wire harness from the ECU and as luck would have it, only the one length of wire that runs from the ECU to batt neg was burnt...about an 18" length. So, I replaced the multi wire ring termiinal at batt neg, ran a fresh wire to the ECU ground with a new ring terminal and tied the timing sensor ground shield into it too. Marty, I think you suggested a piece of inner tube to aid in shielding the corner of the ECU closest to the batt + terminal, I did that too. I didn't realize something you said earlier until I began writing this just now. After I repaired the wiring, put the battery back in, I noticed the spanner laying next the the tool pouch so, I shoved it underneath the tool pouch rubber band to better secure it. You mentioned the possibilty of the spanner bouncing around and contacting the batt+ and shorting against the ECU or other ground in that neighborhood. In retrospect, that might be what happened....damned spanner! Docc, I rechecked all the grounds and added a ground to the VR housing to the timing chest. Thank you for your help & insight. Stay well! Art I1 point

-

yeah, I probably didn't see your point. You probably didn't see mine. such is life in the interweb eh? I have been known to miss the mark on occasion. Just doin' my best to answer the op's query. to the numbers.... 170 is all I've read/heard. Seems like they'rd be more of a mix up on the forums' Tenni regestry if there were more.1 point

-

Wait - whaaaat? Two special edition Ducati SCs with the same # on the triple clamp?? I’d have to see that to believe it. I don’t know if I believe MG would do that either. I sure hope not that’s just NOT COOL. Sent from my iPhone using Tapatalk1 point

-

Thanks Docc. Even though I was fearful of breaking the whole mess, I was well on my way of doing that but the bike finally restarted and ran. Glad to know it's possible to do that. (I have a feeling I'll be attempting a lot of bike "maintenance" over the next few months. You guys might be the few folks I'll be communicating to as well.)1 point

-

The fuse block will actually pry up out of the rubber insulators without using the fasteners. A little at a time, back and forth between them.1 point

-

Updated to reflect changes from page 10. 09 Germany 29 Germany 39 Germany 46 Italy 57 Italy ( in the factory car park) 60 Italy 67 Germany 69 France 77 France 84 Italy 90 Germany 98 Italy 99 Germany 101 Sweden 103 Germany 107 Italy 111 Germany 127 Germany 134 Germany 135 Germany 150 Ireland 165 Netherlands 167 Germany 172 Finland 173 France 180 Germany 191 Germany 200 France 206 Slovenia 213 Slovenia 221 Spain 222 Scotland 224 England 225 Scotland 226 Germany 227 England 232 USA 250 Australia 251 Australia 254 Australia 255 Australia 261 Australia 262 Australia 267 Australia 269 USA 270 USA 272 USA 275 Australia 279 USA 280 USA 281 USA 283 USA 287 USA 288 USA 299 Germany 300 Netherlands 301 France 310 Isle of Man 311 England 313 England 314 England 318 England 344 New Zealand 350 Australia 352 Australia 353 USA 354 USA 358 USA 363 USA 365 USA 370 USA 372 USA 373 USA 375 USA 381 USA 383 USA 385 USA 386 USA 387 USA 389 USA 392 USA 394 USA 395 USA 396 USA 397 Italy 398 Germany 401 Australia 402 Italy 415 Germany 431 Italy 457 Italy 464 France 484 Wales 489 England 490 Wales 494 England 496 England 497 Northern Ireland 498 Scotland 500 England 502 Wales 505 Singapore 539 USA 544 USA 545 New Zealand 546 USA 555 Italy 556 Poland 563 Canada 565 Germany 568 Italy 580 Denmark 595 Italy 597 USA 598 USA 599 USA 600 USA 603 USA 608 Netherlands 617 USA 642 Germany 655 Czechia 666 Italy 672 Finland 688 Italy 699 New Zealand1 point

-

I ripped quickly through a bunch of material; from Guzziology and this site, the cams, part # 3705 3305 on the Sport & V11s are different, there is mention of them being higher lift and if I'm reading the charts right, longer duration. I also read a reference that the valves themselves are larger, just slightly smaller than the size on the old big valve engines. I'm starting to get a better understanding of why Chuck and others have described the V11's as the last of the real hot rod guzzis. The more I'm learning about the bike, I'm getting anxious to get it on the road. Tks1 point

-

It rather surprised ,me when I took my V11 clutch apart, that the toothed plate that has the teeth for the starter to move is not actually the "flywheel" (like the old American V8s I am used to). The V11 "flywheel" is actually really deep in and anchored to the back of the crankshaft. Pretty sure there is no way to get a magnet onto that surface (?)1 point

-

It's the SPOrT-1100/V11 DrJohn/Crane cam, no? And the compromise to make sure the valves seat long enough (loose enough) to cool through the seats? Early, tight (US?) valve clearances were more about noise control? Certainly not about longevity. P.Roper rightfully noted that the looser the valve lash, the less the lift and duration from the cam. Lower performance (?) Trade-offs!1 point

-

Try it. For very little effort, you can add your experience to the forum. I believe that the 4000 rpm hiccup that the V11 engine is prone to, is caused by inlet valve clearange too tight when engine is hot . A bigger valve clearance helped my bike. You lose nothing except your own time by trying different clearances.1 point

-

So I thought I'd have a play around with the throttle bodies and TPS sensor and also confirm my wiring for the PF09 TPS was correct when fitting the old style plug to the V11 loom as the colour coding is different. I made up a 5V power supply and some flying leads and confirmed the TPS read outs were correct and thought i'd do a preliminary set of the TPS which I can confirm when I power up the system on the ecu. bearing in mind that I have no idea how this engine ran or the mileage originally the TPS condition could be anything and I want to eliminate as many variables as possible. mechanically the Throttle bodies are acceptable from a wear perspective although I replaced the plastic connector rod ball assembly. Unfortunately I couldnt get the TPS reading below around 200MV unless I tapped it with a screw drive handle and then I could get it to around 140MV with the throttle blade completely closed which would work if evertime you stopped you tapped the TPS. I ran out of TPS adjustment so I decided to see if I could pull it apart and see what was happening. Although this isnt really relevant to the V11 as it uses the later TPS it might be to anyone following in my footsteps down the track. The PF09 TPS is held together with small metal press rivets so I used a box cutter blade into the joining line and gently twisted the blade to get the rivets to release. Going from one side to the other slowly slowly until I could get a 0.020" feeler gauge length ways into the gap and use those. It helps if you use one on each side simultaneously to prevent the halves rocking as it separates. The whole process took quite a while like 15 minutes but it came apart without looking like it had been apart, ie not butchered. This is the process. And this is what it looks like apart. Note the crud and rubbish on the wiper fingers and also the foam seal and rivets. Also note the strong return spring and wiper faces. Here it is again after cleaning with a very small paint brush and contact cleaner followed by contact cleaner and cotton wool buds. Here you can see the closed stop screw assembly. So after cleaning I hooked it up to my 5V supply and checked the operation. Still not able to get it below 190MV but it was stable now. So next step was to adjust the stop screw. Nothing magic here just adjusted it until the reading bottomed out at 14MV and left it there. Not sure why this was the way it was, dont think wear was a factor, maybe it wasnt adjusted properly from the factory. Dont really know. , Wide open throttle, 4.76 volts which is the nominal voltage of my power supply. Anyway re assembly is simple just put the halves together and use a small tool to press the securing rivets back in place.I also changed the securing screws over to the Torx type I had off another set of Ducati throttle bodies as my original straight slot fasteners were a bit ropy. Ciao1 point

-

This is a really excellent question for @Meinolf No doubt, his are the most thoroughly and precisely developed V11 maps, ever. What would be the effect of using the latest Meinolf map with the more typical, closer, valve clearances (0.15 & 0.20mm/ 0.006"/0.008") ?1 point

-

1 point

-

The most likely culprit that would melt up the ground side of the harness is a corroded, failed main grounding point behind the seat latch lock at the rear of the gearbox on the right, perhaps along with corroded/loose/failed battery terminals. This fail can go really badly for the minimal grounding back through the harness along the frame . .1 point

-

viewed through that filter, all the V11s are the same, ...with varying paint scheme, and tidbits to make it different, and all to arrive near the same price point. If adding Ohlins to a RC, NC, CS is a mere upgrade, then so it be on a Scura. Tho not a limited edition a Cafe Sport is a newer Scura, but with an unfortunate name and all the Scura flaws removed. The later Ohlins is even improved. my list is just what I think will pan out over the years. 170 Tenni, 600 Scura. One collector will value the more rare, another will want Ohlins. I don't care how it turns out. I bought mine for the look of it.1 point

-

"Wiggle Test" is something I learned from a book on "Preparing the Ford Sierra for Motorsport" (The US Merkur XR4Ti). That thing made the V11 look like the pinnacle of engineering and design success. What the relay/fuse wiggle will not find are the nefarious, hidden spade connectors under the fuse block for Fuses #1/ECU and #2/Fuel/Ignition. One of those jiggles loose and it can drive you mad.1 point