Leaderboard

Popular Content

Showing content with the highest reputation on 03/20/2020 in all areas

-

4 points

-

Today is the first day staying at home in California. I took a pre-dawn walk with the dog to the main street at the edge of my neighborhood. Still some light traffic, which I assume were people on their way to "essential work" such as healthcare, sanitation, power supply, etc. Saw a couple big military trucks roll by. Wednesday, a solo military helicopter landed at our local airport - I assume the passengers are now in charge of that airport. My daughters are all home (one returned from college a few days ago). So we are safe and stocked up on essentials. Taking a cue from the Italians, we've got a load of pasta and tomato sauce. I'm all set up to work at home (have always maintained a home-office), and putting in long hours. My business is hit hard by this and we (like most other small businesses) are scrambling to figure out what this will mean to us. In each of our offices (UK, Singapore, 3 in the US), we made everybody take home whatever they needed to work from home. Yesterday, we did a video meeting and showed off our new "offices" to each other. We went totally virtual as we are expecting this restriction to go nation-wide. Last night (hours before the California stay-at-home deadline), I delivered a bunch of food to one of my team who has a high-risk profile for this virus - he is on self-imposed 100% quarantine till this is over. He said (though his upstairs window) "You don't realize how much certain activities mean to you until you can't do them." I told him to remember that he has a rebellious friend with a dirt bike who knows how to find things. This thing is totally surreal. A few weeks ago, I made my family watch the movie Contagion. They didn't think that was going to happen. But here we are. I hope Moto Guzzi (which is near the epicenter of the Italian outbreak) can make it to their 100th birthday. Thanks Jaap, for opening the dialogue and for setting the apolitical tone.3 points

-

Yes docc, the main issue with the V11 is the frame design. A single spine doesnt leave a lot of options for routing wiring and cramming in things like fuel pumps and filters etc thats why I think the later in tank pump arrangement is a bonus. Gets a couple of large bulky items out of the way and simplifies the plumbing and makes tank removal less messy. The V11 though comes from the same era of design as the 851 Ducati which was literally a frame, engine, swingarm forks and wheels set on a lift and they then built everything around that.Old school ad hock design which makes them messy. The 916 Ducati was a massive leap in this regard as it was CAD designed and fitted together like a watch by comparison. Ciao3 points

-

2 points

-

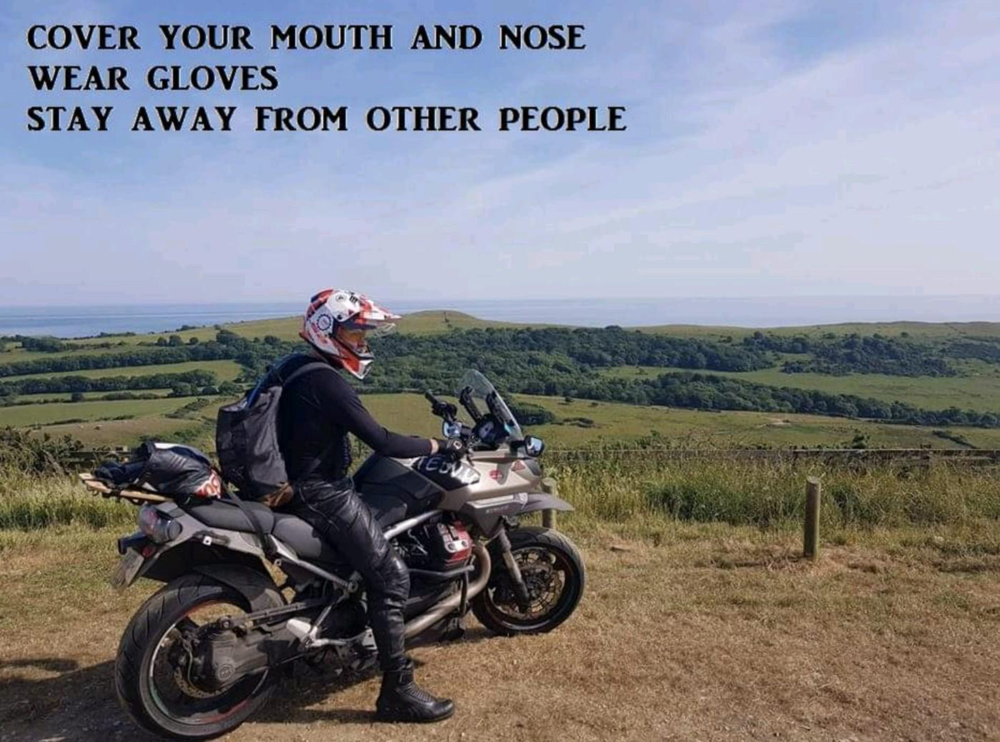

Doing fine, but there appear to be unreported symptoms with widespread community transmission. To wit....what I see in my efforts to promote social distancing..... What everyone else sees....2 points

-

It really has been surprising just how tightly packaged the V11 is. To fabricate a fuel tank (or install a V10 Hi-cam!) is truly an amazement!2 points

-

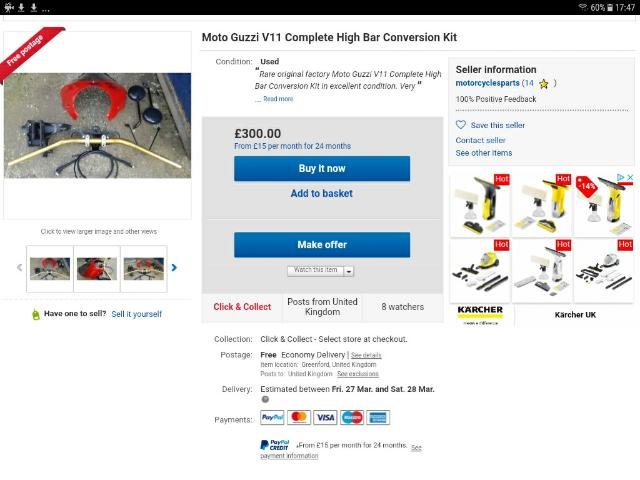

I spent a lot of time and mental energy trying to find a solution for fitting an internal pump to an older external pump tank and shelved the idea. Like most things its probably possible but just too hard to physically do. My criteria was to be able to fit a pump and filter inside the old style tank without modifying the tank itself. Ciao1 point

-

The Stelvio does not have a US plate, but the lad's calves aren't big enough for it to be the Scottish coastline . . .1 point

-

1 point

-

I have a couple of jobs coming up where i’ll be the sole person on site so, assuming I can purchase the materials I need, I may be able to crack on somewhat. We’ve our 17 month old spud, who’s 30% whingepig/70% delightful, at home so spending time with my family is a pleasure. Seeing society go thru phases of panic, madness and mis-information is weird though... What was that phrase: “Any society is only three missed meals away from chaos” (or something similar)? Makes sense, whereas “Any society is three sheets of bog roll away from chaos” has a different ring to it. Social media has made me realise that the world’s actually full of experts...1 point

-

1 point

-

I have check it when i separated the engine from the gearbox, it all looked okay!1 point

-

You would need to get an aluminium mount plate made up to mould into the new tank. Easiest way would be to take a mould from the later tank. I've made fibreglass fuel tank moulds and tanks from scratch as well. The wiring for the internal pump is no big issue just a wiring splice and plug for the level sensor and pump. Ciao1 point

-

1 point

-

Everyone seems to be forgetting that when the engine is fitted you get a massively rigid structure esp with regards to twisting. The truth is this thread is all a bit crazy to be honest. From someone that has bought around half a dozen wrecks and repaired them the only way to be sure how straight they are without alignment tools is to check the vulnerable areas like engine/gearbox mount points for cracking and steering head area for distortion and eye up the forks in relation to each other and put your hand up at the auction. Get it home and evaluate properly stripped down and hope you got it right. Its always worked out fine for me. Most bikes dont get bent unless they hit something fairly solid or cartwheel and then you generally get frame member distortion and or engine mount damage and bent forks. Ciao1 point

-

I found the laser alignment fight club thread. Looks like the intent is to shift the whole swingarm across rather than each end fore and aft?1 point

-

Full circle. If both wheels are plumb up and down at the same time then both wheels should be pointed in the same direction. Anything else is frame twist. Can the rear swing arm adjustment screws accommodate a bit of that twist? Do they do that in the factory as a final assembly step? I never heard of it before.1 point

-

Forgot to mention: It can be critical to make certain the fairing is not pre-loaded when mounted. If the mount bolts pull it into the mount, that creates surface stress that can lead to cracks. I shimmed mine with rubber washers, so it is not sprung either out or in and has just that much more vibration dampening.1 point

-

1 point

-

I have no idea where I would find 8ft fluorescent tubes let alone the regular kind. I invention mode, I could make a couple of crude bow strings. Nothing as straight as a line tight between two points, save the sag in the middle. I had no idea there is adjustment available in the swingarm! Is that on a particular axis? A chalk line is pretty straight? That would be a lot easier. The bike sits on a nice concrete floor presently but not a whole lot of room around it. There's no hole through the porkchop and frame on a Tenni to poke a pipe, ideal as that would be. It is doubtful how much I can get the wrecker crew to play helper. They will have a hoist but whether it has an engine hanging off it when I get there is unknown. I remember I used to ride a Vespa. The front wheel was parallel to the back but a good 1.5'' out of straight line! I think it might counteract the off centre weight of the engine. So the defining characteristic is parallel axes? Even harder to measure. Pausing for thought. Manipulating coffee cups... ...doing head in with the 3D nature of it all. Leaving it for a bit. Keep the ideas coming.1 point

-

1 point

-

Never thought of that, didnt realise they were dead straight. You learn all sorts of things here:) You can of course source yourself a piece of 50X20 aluminium rectangular tube and adjust it for dead straight then drill 4 holes with bolts 2 at each end that are spaced to rest on the fwd and rear edges of the rims to check the alignment. Then you can use it on any bike by just drilling extra bolt holes to suit differing wheel bases and use longer/shorter bolts for different wheel width combinations.The vertical you do with plumb bobs. The trick is knowing how much misalignment is production based. Ciao1 point

-

Some of the later injection systems are a variable pressure arrangement that vary the speed of the pump via the ecu as a primary control of pressure and therefore dont require a return circuit and regulator but you could in principle use any pressure source and reg you like,BUT take it from me after years of experience with these sort of things its wise where possible to not mix and match components from different manufacturers and systems to this extent. If you use the later V11 system you take out a whole lot of possible variables on a whole lot of levels and when and if you run into an issue at least you know you are dealing with a system that is proven to work on your specific installation. A large access hole is an advantage not a disadvantage foe maintenance and possible repairs. If you want the cheapest possible solution then go with an external pump,reg and filter for sure. Just 2 simple and cheap spigots to incorporate into the tank. Ciao1 point