Leaderboard

Popular Content

Showing content with the highest reputation on 10/18/2021 in all areas

-

Most of the time...its " Sweetheart".. Occasionally .. it's "You heavy bastard"3 points

-

best way to acquire spare nuts + bolts + doodads you didn’t know you had!3 points

-

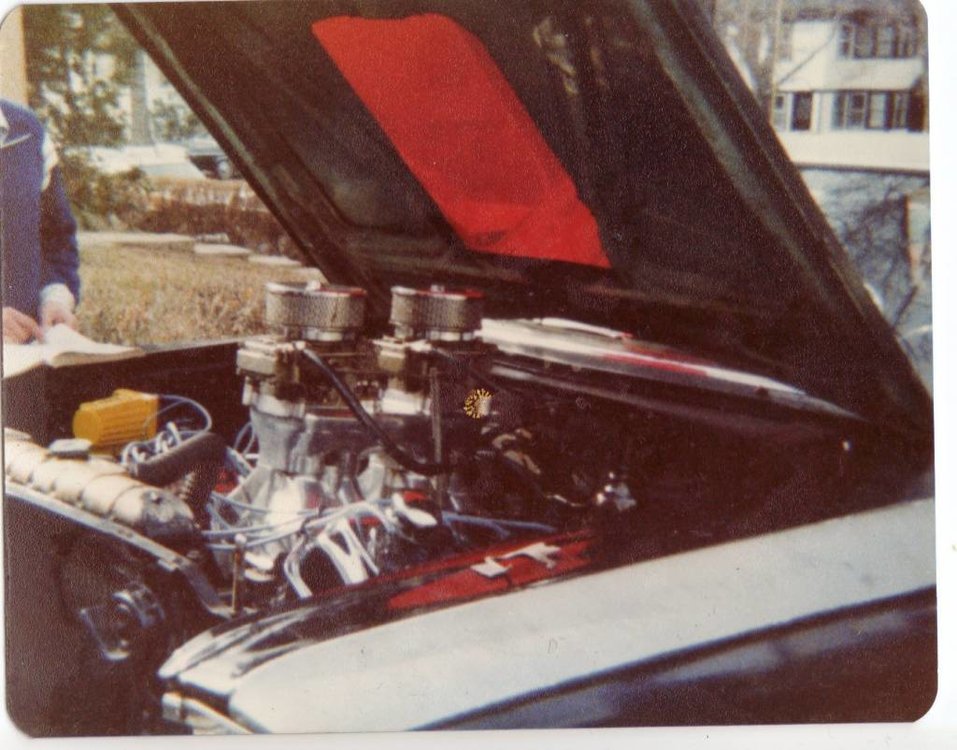

Electric(al) on cars makes sense to me. Like this insane yellow (Accel?) coil that @Tomchri shared with us last year. Pretty sure "dual quad Holleys on a tunnel ram" offer up emotion enough! Maybe some "Hooker Headers" to stir the mix . . .3 points

-

Hibernation is approaching for me as well. Once November arrives and the gritters start salting the roads, that’s it for me until March, unless we have a mild spell when the roads are free of salt. Oh to live in a warmer climate…….I was originally intending to go out for a ride today, but it rained most of the day, & apart from moving a bike in and out of the garage, I didn’t venture anywhere3 points

-

That's a question for the factory cause that's what they did and the answer is a simple one. It's more in their interest the bolts never come out unintentionally than it is to make any replacement/maintenance straight forward. Future maintenance years or miles down the track is of zero concern to the factory. As a matter of fact if components get damaged during future maintenance then they make money out of spares. Witness the Weber throttle bodies 5mm screws fitted with green Loctite for goodness sake. Weber have zero concern for anyone disassembling them in years to come but are quite interested that screws dont loosen any time in the near future which may bite them. Blue Loctite would be understandable but Green just says "we have zero regard for future maintenance" Ciao2 points

-

Lovely. You know docc for me the sound and "feel" of a vehicle are massively important and why if I'm forced into a situation where every vehicle I own has to be an EV I'll just find another hobby/interest. Don't mind an EV Daily Driver in the slightest as a conveyance to get me from A to B but I could never become an EV "enthusiast". Too much character missing. As an aside my car has FENG ( fake engine noise generator) which is fake exhaust sound through the audio system, totally pathetic and it doesn't really need it anyway. That's maybe the EV future, a fake " emotional" system. You'll be taking your car to the mechanic because it "doesn't feel good" and he'll reboot the "emotion" generator. God help us all. Ciao2 points

-

2 points

-

Not everyone would watch (and listen!) to 27 minutes of car noises. Admittedly, I have a decent sound system to play these sonorous tracks through. I got hooked in the first six minutes thinking, "Nothing here wants to idle or run at less than 5,000 rpm!" (Just like mySport . . .) Then, they turned them all loose!2 points

-

Some things will not be forgotten. Old HEMI'S do have a spesial way of singing to, she was a Keith Black edition. Fresh battery was a must, serios carb fire every startup, hi lift cam. Hit the starter again and suck in the flames,, there we go. Chrashbox, was it AP 833 ? And yes Doc Hooker headers. Fuel lines = garden size hoses, but fun fueling that Belvedere, real family car. Wish I had a sound track. First dragrace in Norway was in 1978, runner up there with a 71 Charger R/T. Bla bla campfire talk. IPA time. Cheers Tom.1 point

-

I have done a few over the years as well............ The big trick on these is saving the very hard to duplicate finish on the wheel. Ciao1 point

-

If it is restricted to a relatively small area, some of the more volatile chemicals can be used on a Q-tip or cotton swab. I have found that some experimentation is needed to remove various stains. If it can soak, it will come off better, but how to soak fins? Maybe soak a strip of paper towel and wrap it around the fin.1 point

-

Don't have a V11 but my Bellagio is "Bella." And something else in Italian if it doesn't start....1 point

-

I learned about SuperClean® from @Chuck. Carefully hose it off after it sits a few minutes and use a blower to dry the engine and everywhere the hose splashed. For baked on oil, I will sometimes use mineral spirits and a soft Nylon brush (toothbrush or parts cleaning brush).1 point

-

It's easy to remove the broken bolts to the rotors if you have a mig welder, just place a 8mm washer or nut over the broken bolt and weld a bead to fill the hole (try not to over heat it). The heat usually is enough to release the locktite and can be removed easily unless it was cross threaded. I have done a few over the years this way.1 point

-

OK.............. so no one has a decent 5.5 wheel for consideration??1 point

-

1 point

-

Quite disturbing to imagine the shaved ape who is given the job to "Bust it to the smallest bits and tie toe tags to the results." Reminds me of a guy we hired to "deconstruct" our kitchen. That he did. Yet, we never intended to offer up the debris for sale.1 point

-

Even worse, the "breakers" that take assemblies down to their smallest bits to re-sell each little part individually.1 point

-

IDK why these people have to Loctite these rotor bolts to the wheel ? It is an effort to get these loose/off in less than 6 hrs. time .1 point

-

Sounds feasible. Something like this may work but why not buy an original Ohlins and do as I suggested. Take the guess work out of it. https://www.suspension.com/9.91491 point

-

Last ride before hibernation today, l think. Nice weather with 6c. Home 6.30,, 2c = V cold knees. Cheers Tom Sent fra min SM-A525F via Tapatalk1 point

-

This Sport officially made 200.000 km today. In fine form. I pulled over to record the moment. The most poignant feature in the image? The road ahead!1 point

-

Consider it done! Glorious 133 mile day on hilly backroads, almost no traffic (I did pass that one Porsche. Because I could.) Perfectly clear, dry 60ºF/ 16ºC. Not the greatest view, but gives an idea of the roads here. This is the point that mySport posted an honest 200,000 kilometers. And ran sooooo great all day!1 point

-

https://www.ebay.com/itm/133447808196?hash=item1f121bf4c4:g:-fkAAOSwB5Fe87WI Used, but it's a start. Paul B1 point

-

The bump stop. It's what prevents damage to the shock internals when it bottoms out. You need to remove the spring and the eye end to replace it and removing the eye end is no joke even for a "shock expert". It involves heating the eye end to get it hot enough to to release the thread locker then a shaft holding tool, sometimes even in a shop press to hold the shock shaft to undo the eye end. I would cut a shallow groove around the perimeter of a new bumper that will accommodate an electrical tie wrap then cut it so you can spread it and slip it over the shaft and use the tie wrap to clamp it in place again. Ciao1 point

-

1 point

-

Probably the ground to the ECU, This will fry pretty quick if you try disconnecting the battery terminals in the wrong order then accidental let your wrench touch the ECU Always disconnect the negative terminal first, reconnect it last that way there is no return path to fry little wires,1 point

-

John asked me to look in on this thread, I used to know quite a bit about these systems. Firstly the alternator wires can be a problem, they snap off where they solder to the coils. When this happened to mine the copper was so corroded it was not possible to re-solder them so time for some new wires, its quite easy to solder the new copper to the coils. The bullet connectors where the regulator plugs into the stator leads often overheat, if this is a problem just chop the bullet connectors off and join to the alternator with crimp links or a solder joint. Grounding the regulator is critical, all the charging current travels back from the chassis to the regulator case so it can return to the alternator through the other yellow wire. The factory supply a small black wire from the case all the way to battery negative but this is far too small for the current involved. Run a short wire from the regulator case to a timing cover screw, the engine and battery main ground are massive compared to the tiny black wire. The regulator has a rectifier set up as a bridge, 2 diodes and 2 Silicon Controlled Rectifiers. The rectifiers sometimes go open circuit, this situation is very easy to set for if you have a meter with the diode test function, The diodes are connected from each yellow wire to the red wire, it should show about 0.5 Volt, since the diodes are between each yellow wire and the red pair its possible to add a diode on the outside. The way they measure the battery Voltage is very poor, it taps off the feed to the headlight after the headlight relay and in some cases a normally closed contact of the start relay. The relay contact and socket resistance changes with time, the Voltage drop can be anything from 0.6 to 1 Volt, I have a theory that the reference voltage drop approaches 1 Voltmeaning the battery Voltage has to be pushed above 15 to supply the regulator reference, this high Voltage demands more current which overheats the diodes unit the leads melt off. A warning sign can be the headlight out or the tachometer not working, chances are the battery is not charging and of course the charge light also fed from the headlight relay won't be working either fooling you into thinking everything is ok. I often thought of getting the Voltage reference from a different source downstream of the ignition switch, off one of the ECU relays or from a dedicated relay direct from the battery. This would give the regulator a lower Voltage reference because it expects a drop through the relay but it could easily be compensated for with some resistance ora diode in series. I struggled with this flakey Voltage reference for years then I upgraded to a permanently connected regulator from Electrosport, there was one minor drawback a parasitic drain on the battery, I used to disconnect the regulator over the winter but if you don't remember to re-connect it next thing you know the bike dies with a flat battery. Electrosport recommend their ESR515, I dont agree, it still relies on the flakey Voltage reference and a good ground connection. I used the ESR510 it is wired direct to the battery and it has a dedicated ground wire I don't think it supports the charge light. Instead of a charge light I recommend just purchase a battery Voltmeter for ~ $15 and hook it downstream of the ignition switch this will leave you in no doubt. https://www.amazon.com/12V-Voltmeter-Color-Digital-Display/dp/B07HHTZ1L5/ref=sr_1_46?dchild=1&keywords=12+volt+battery+meter&qid=1633586264&sr=8-461 point

-

^ side stand switch is easily by-passable if you are in need. Same with the clutch-in-to-start switch. I carry a side-stand bypass plug (homemade) in my underseat kit. Hacked the connector off an old wiring harness and closed the loop. Honestly, to start this bike... ignition switch, kill switch, clutch switch, side-stand switch, neutral switch, starter button, relay, starter solenoid, battery amperage, starter motor... what could possibly go wrong?1 point

-

1 point

-

Today, I tested; The old starter, when hit with the battery, actually turned- and intermittently spun, slowed, stopped, shook loose and turned again. I performed amp draw (best I could holding the meter and screwdriver) I used a good automotive battery on the old starter, so it may deliver more peak amps than the bike's Odyssey. That said, test results peak observed amp draw; New starter, 54a to start, ~40a turning the motor Old starter; 80a min turning, 394a siezed. I did not miss the decimal point.1 point

-

Looks like it comes in the original colors, so I assume it is made for the red-framed bikes. Does anybody happen to know the cost or whether it will also bolt up (without modification) to a longer, black frame? As exhaust, I have not heard the Magnis, but I've heard Mistral and Staintune. Those are nice, but the best sound, (IMO) is from the Moto Guzzi Factory Titanium Racing cans. Sadly, if you want a set of those, you probably have to buy a motorcycle that already has them.1 point

-

Yes, yes, those AC readings are between the two yellow alternator output wires disconnected from the wiring harness.1 point

-

No apologies necessary! Pretty sure @Weegie (and others) get as much out of these puzzles as I do. The V11 Workshop Manual give the following values for alternator output in AC volts: 1000 RPM 15 vAC 3000 RPM 40 vAC 6000 RPM 80 vAC If your alternator is not functioning, I don't think the regulator can be evaluated solely on the present voltage reading until the alternator is actually putting out. There are some resistance and diode tests that can be performed on the regulator statically, but seems reasonable to get the alternator around and recheck the running voltages at that point.1 point

-

Last thing from me If that was AC Volts and not DC Volts then it's definately defective, ideally the test is carried out using a good quality meter. In the thread docc pointed to you can see warnings about cheap meters having problems with AC ranges. If the meter was set on DC Volts I'd expect a small reading as there usually is a small DC component. EDIT Thinking about this some more I realized you still had the alternator connected to the Reg/Reg when you took the 3.5-4.5V measurement, if I understood you earlier. The Voltage test needs to be conducted with the Alternator "Open Circuit" (in other words disconnected from the Reg/Rec), so no idea what voltage to expect measuring that way. This is from the Centauro manual but I'm pretty sure the V11 runs the same alternator Alternator With the engine switched off, disconnect the two yellow generator cables from the rest of the system and then carry out the following tests with a ohmmeter: Check the winding isolation towards earth Connect one connecting point of the ohmmeter to one of the two yellow cables and the other connecting point to earth (laminar pack). The instrument should indicate a value above 10 M Check the winding continuity Connect the two connecting points of the ohmmeter to the two yellow cables. The instrument should indicate a value of 0.2÷0.3 . Good Luck with it, it does sound like it's defective and you're well on the way to getting it repaired1 point

-

I saw that on the link you provided. It's oddly beautiful, I'd feel bad burying this object inside the little alternator house. I'll print that out and show it to the local guy, sure he's seen a lot of hardware in his day, I'm thinking this one will melt his jaded heart.1 point

-

Certainly doesn't sound very promising, I'm curious about the 3.5-4.5 readings what was that Amps? Best way to check the Alternator is to disconnect the 2 yellow wires and put a meter on them. Set the meter for AC Volts range 60 or greater and rev the engine to 3k, you should see 40 Volts AC and 15 Volts AC at 1k or so if it's good. I prefer to run it up to 3k as you're not flogging the engine to death mechanically unloaded but have the revs high enough to ensure the Alternator should be giving you an output Of course when you disconnect the the Alternator you're running on battery only so top up the battery on a charger afterwards1 point

-

Very common for a yellow output wire to break off at the stator. It is rather hard to see. I replaced my last one with an improved stator from EuroMotoElectric, IIRC. It has improved heat shielding and strain relief. I should be able to find links to that thread, the supplier, and post images in a few hours . . .1 point

-

Quietly, softly, the recognizable tune of a Funeral dirge can be heard coming from somewhere, difficult to locate, in the workshop....1 point

-

I came across this delightful video of The Goodwood Revival. Something for everyone (even bikes)! Makes me so want a car that just will not idle . . . .1 point