Leaderboard

Popular Content

Showing content with the highest reputation on 11/09/2021 in all areas

-

Boy, do I know that feeling sometimes! Well, I stopped by Seacoast Sport Cycle (love these guys!) last week to drop off my Roper Tray which they will install for me. All seems to be well with my V11 Sport. Should be done this month and dropped off with a totally dry fuel tank for my Winter storage. Their report is all the fluids before draining were really clean, except the brake and clutch fluid. Those were a wee bit dark. Fork oil was changed, seals on them were good. Drive shaft was greased, as were the chassis/swingarm bearings. No signs of terrifying glitter in the bevel box, trans, or oil, so...a big whew at that! New Pirelli DIablo Rosso IIIs got installed. All fuel and vacuum lines were also changed (they were 20 years old). There was a breather hose/valve on the engine that needed replacing, so they replaced that. Valves were adjusted, new plugs, and throttle sync is the next job w/the Roper Tray and a quick road test before I get her delivered back. They did say the tank swelled a little bit but drying it while empty out over WInter will let it shrink back into place. I am relieved I didn't buy a pile of junk. She has just under 13k miles, and the speedo and odo drive both still work. All in all, they said I got a great machine that needed hardly anything. I should have her delivered to me by the end of the month. Come Spring, I will top her off with some new 93 octane, put in the charged battery and start really riding her. I am so excited to finally have a Guzzi V11. April/May can't come soon enough!3 points

-

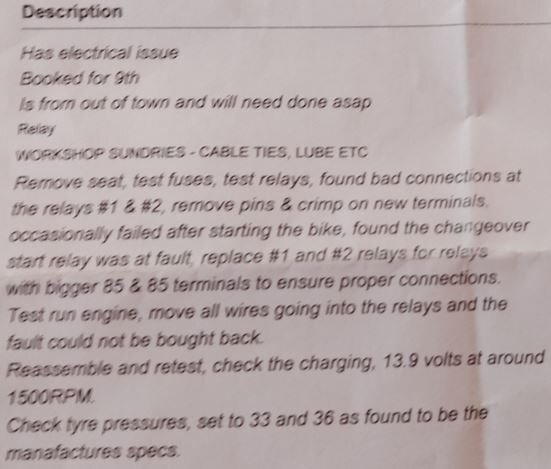

All fixed. Bike shop found relays 1 & 2 not contacting. Invoice has full explanation. I can't up load it off my phone but I've emailed it to MartyNZ. Maybe he can. Back on the road soon. Off to Wanaka3 points

-

Not sure docc as I try and avoid venturing into the Periodic table and "theoretical outcomes" if my personal experience indicates it's not an issue. Titanium is 22 aluminium is 13, is that bad? Uncoated Titanium can "gall" against itself as in a TI nut on a Ti axle but I've never had an issue on aluminium. Having said that it's recommended to use a copper based anti seize on the threads which I always do. You may remember I used a bit of Ti for bolts and bushes I machined up for my tank mount on the V10 Sport. I'm also considering making Titanium axles for my bike. I've priced the raw material and it's not a massive cost so if I can locate some KT forks I'll do that. Ciao2 points

-

I got the good news today, my V11 Sport is done. Nearly $2k, but she's in top running order for next Spring. Next week she will be delivered to my storage unit with a totally empty tank. I will remove the battery and keep it on a maintainer, and I and my V11 will be ready for the warm happy roads ahead in 2022. I want to thank Seacoast Sport Cycle in Derry, NH for getting my bike in and taking good care of me. They aren't cheap, but you usually get what you pay for. Love these guys.2 points

-

If the threads were to strip out it won't be the SS bolt, you'll be repairing the engine block or what ever the bolt screwed into. I used to think they were cool. As to the turning out the Allen head, do you have good hex wrenches? some (craftsman) are just slightly too small for a snug fit. Do you use anti seize? I rarely ever had a problem with Allen heads unless they were in there for 20 or 30 years on some old clapped out Tonti frame.2 points

-

2 points

-

I have put TLM on my bucket list, for the next time I am in The Netherlands. I also found out they rent Moto Guzzi bikes. I lived and worked in Alkmaar in 1982; lots of my local colleagues motorcycle fanatics!2 points

-

While I’ve been careful to apply a good coat of grease to the SS threads to prevent the galvanic corrosion, the apparent fact that it will be the aluminum that is lost, not the cheaper and easier to replace SS fastener, steered me away from SS in aluminum. Does titanium not have this same corrosive characteristic in aluminum?1 point

-

I have used s/s fasteners on all my bikes since forever. I learned early on to not rely on them for high torque spec applications. Also to make sure threads are de-burred and if the fit is tight into alm, I won't use it there either. Hard metal cuts soft metal, only takes once to learn that one. S/S in construction applications have shown them to be soft and easily broken when torqued a bit too far. Small or shallow allen head will round out easily and as has been said, use snug fitting wrenches. They work great for all bodywork, controls, footrests, switch-gear, number plate, etc where you normally get annoying rusty bolts.1 point

-

I was doing some research for Joe Caruso on the latest iteration of his aftermarket oil pump and was postulating along with him on the reasoning behind using helical gears in the std pump as opposed to straight cut gears. I was looking at one of my pumps on the bench and the only advantage I could see was that as the gear tooth passed the inlet and outlet ports in the housing it did so in a gradual manner due to the angle of the tooth and not open and shut as a straight tooth would. I thought this would lead to less pressure spikes and a more constant delivery. So after about 3 hours of research I found that I was indeed correct and even found a pressure graph demonstrating the differences. Another puzzle solved and the satisfaction of realising that I had worked it out myself and the thought that maybe just maybe all the time I've devoted to thinking about "engineering" over the last 50 years or so has actually taught me stuff. A rare moment indeed. I once read as a teenager all about the pros and cons of Georotor pumps but have forgotten what they were, lol. Time to revisit. Ciao1 point

-

Thanks for all the advice. But please accept that in over half a century of riding motorcycles I have never had an issue with stainless on engine covers. Will report back if my sump falls off but with 14 bolts holding on something that is about 300mm square I think that overkill comes to mind. Chris.1 point

-

Ever see a moment pass by when you have specific information, but wonder if it should see the light of day? This is one of those moments. There was a discussion about oil pumps back in the '90s when I was racing 883 Sportsters. They have a georotor oil pump. The question at hand, an academic one, is why H-D went to georotor after decades with a gear pump in that place. One guy who happened around during the discussion was an automotive engine builder of some renoun; he said he'd been told that gear pumps with high pressures had the problem of pressure spikes when they were too tight, and that bleeding mitigated those spikes. No consequence of those spikes was put forth. The trade-off was that idle oil pressure was reduced. Upon building a small-block Chevrolet for my pickup truck last summer, I saw offered a spiral-cut gear pump for high-pressure/performance applications, with the claim to reduce pressure spikes. The claim was that these pressure spikes increased hydraulic lifter pump-up particularly in 'stock' or 'limited modification' engines. Meh. Who knows? H-D went to the Georotor pump at the same time they started using hydraulic lifters in the Sportsters. I do know that in most American engines, distributor/oil pump drive gears are a point of failure, and it's critical to choose compatible components. Maybe there's something there on the durability scale. My daily navel-gazing.1 point

-

There's quite a bit of loss through a gear pump. There's the tooth tip to housing clearance and the gear end clearance to the crankcases. With the small volume your hand pump is delivering you'll notice these accumulated losses. I understand your reasoning here with priming but it's a bit of an overkill. The oil cooler really doesn't come into it as it's not in the oil delivery system until the thermostat opens anyway although there will be some leakage and that will gradually fill it until the thermostat opens. On a new engine it's worth running the pump off a hand drill when the front cover is off but otherwise not really necessary. Ciao1 point

-

1 point

-

Cheers for that MartyNZ! Those two gears sandwiched together just looked a bit incongruous especially when the gear in front is max’d out with all those lightning holes! Hmmm okay then... possibly more outlay in custom machining in the course of Joe’s gear installation. I mean, if you’re going to do it - right? Minimising rotational weight has additional appeal - makes sense if considering going to those extra lengths of investing in timing gear$ Do you think a someone’s been there done that...? Proportions may be a little large but here’s a quick mock-up of 10/tenths of extra squeeze!1 point

-

If I'm reading that right, then it would appear the switch is working. The circuit is simple, so forgive me spelling it out. Pos supply from fuse box to bulb, then bulb to switch, then switch to ground (inside the switch). No pressure, OP switch is closed and path to ground established, circuit made and bulb lights, <5-10psi. Pressure, OP switch opens breaks the circuit, no path to ground, bulb goes out, >10psi The switch has to have a pos supply to it and that path to ground for the bulb to light. You don't have a paddock stand, that's going to make life harder, but why can't you drop the sump on the sidestand? Does the stand get in the way of dropping the sump, as I don't own a V11 I'm unfamiliar with the specifics? With the sump off you should be able to check the filter for double gasketing, then remove the internals that live inside the spacer (4 cap screws to remove). With the internal assembly removed you can check the gasket condition of the sump spacer ensuring no oil way holes are blocked, as I recall the gasket can be installed 180 degrees out, or it could be torn or damaged. With the internals on the bench remove and test (or take it to a garage) to test the relief valve.1 point

-

Yes pretty much all except the 10mm suspension bolts and engine mount bolts. If you turn the heads out on a titanium fastener you're doing something wrong. The beauty of them is they look exactly the same after 50 years as they did the day they were made. If your keeping your bike long term they are worth the money and if you don't then you just spend an hour or so refitting the original bolts when you sell it and use them on the next bike. The majority of fasteners on just about all bikes is M6X25. I can tell you one thing, aircraft don't use any stinking SS fasteners. I'd use a passive plated steel bolt over a SS one every day of the week. Ciao1 point

-

That's the phonic wheel. As the teeth go past the rpm and TDC sensor, the sensor gives this information to the ECU. Now you mention it, it could be lightened, but just not the diameter or tooth mass.1 point

-

Steel bolts fit the price/performance sweet spot. Titanium is almost as strong, lighter, but more expensive, Stainless steel is shiny.1 point

-

Only that it makes a poor material for a fastener. It's a boating world thing and they need something that can survive a salt laden environment so put up with the negatives. If you want the gold standard in a fastener then use Titanium. All my bikes have a high percentage of Ti fasteners. Light, strong and ductile so they stretch and hold their tension. SS is too hard and lacks ductility so they don't stretch well so lose tension. Ducati tried them as engine cylinder studs at one time and I mean "one time" and had a recall to replace them after they started failing and they were 10mm studs about 180mm long. Junk for fasteners. Ciao1 point

-

Had no issues with stainless, but I only use them on light torque places. Check the sharpness of the treads of the stainless bolts, a fine file, or some 500 paper and a brush, just me. I use some alu smear for the clean trads in the block. Coud ad 20% of torgue, so nice and easy does it. And Valpolini gaskest where possible. Cheers Tom.1 point

-

There's a difference between a bench test at room temp and no vibration and a switch operating in a 100 degC vibrating environment. Buy a new switch anyway and check the filter and the oil pump pickup screen and the adaptor plate orings which do go hard after a while. Also have a look at the big ends to see if there is metal squeezing out the sides. If you still have no joy then it's likely you'll need to remove the front cover for a look at the pump and drive. Ciao1 point

-

Here's a post I made previously on charger use: https://www.v11lemans.com/forums/index.php?/topic/20617-charging-the-battery-hooked-up-in-the-bike-bad-idea/#elControls_236544_menu1 point

-

Okay, I had the similar idea yesterday to try to pressurize the oil light switch, and so today I jury rigged a tire hand pump to the fitting with duct tape (what else?) and hose clamps. With the ignition on and the oil pressure fitting out, no lit low OP light. With an electrical lead from the OP lead to ground, the light comes on, so the circuitry outside of the OP switch appears to be working okay. There was some leakage with the test set up, so no constant pressure reading was possible, but I think I could get up to a transient maybe 20 psi. Whatever, with the ignition on and the switch connected, the OP light went out when I pushed on the hand pump at about 10 psi or thereabouts. So the switch appears to be working, and the malady lurks somewhere else. I was hoping to avoid removing the inside oil sump shell, but that looks to be the next move after I remove the oil filter to check for a missing or double gasket. First I need to devise some way of keeping the scooter upright after removing the side stand. Sigh.1 point

-

@Admin Jaap shared this cleverly insightful tutorial about The Netherlands before. Worth reposting!1 point

-

Well, here's what I STILL HAVEN'T done to my Scura: 1. Figure out the "thin" clutch engagement / feel at the lever. Related to below .... ? Some say poor adjustment due to hydraulic master, but can't suss that out. 2. Get off my ass and commit to inspecting / replacing the clutch / clutch plate or give it to someone who can get there. Looking at the plate is more of of a sense of comfort than a redline requirement, I suppose. 3. Repair / replace the shift spring and pawl bits. 4. Cam chain tensioner upgrade. I'd hoped to have done this last winter, but just waffled. Everytime I come back to the forum and the related threads, I get the overhelming sense that a guy needs to be a master machinist with an M.E. to get to the finish line. I fear that I'll end up with boxes of parts and a roller in the bed of my truck headed somewhere to correct my errors.1 point