Leaderboard

Popular Content

Showing content with the highest reputation on 07/24/2022 in all areas

-

Or go to a bearing supplier and source a Unidirectional seal of the correct dimensions. These bikes are so old now that the Guzzi shops just source general stuff like seals etc. The Guzzi factory hasn't stocked v11 parts for years. Sorry by OEM I meant the original type of seal fitted. Phil2 points

-

Can't make RPM without air, it's getting in there somehow. Spray some liquid- I like WD40, or alternatively a combustible carb cleaner etc.- on the intake manifold gasket area and also the boot sealing joints. If you hear any change in RPM, you have a leak. Check to see your idle air screws haven't fallen out (never heard of such) The last time I had a high idle, it took a minute to figure out I'd left the 'choke' lever partially engaged. Regularly, my Kaoko cruise control drifts enough to make a high idle. This is one with simple answers, as fuel and spark cannot make RPM without air.2 points

-

2 points

-

That may indeed be what will happen. If the gauge wasn’t working properly, getting it off to Joel would be the ticket i think, and then may as well do the proper straightening. But if the MGcycle part addresses the reset issue (which from what I see now is common), then no other reason at this point to tear into it, so the JBweld may be the most reasonable answer. the outer plastic cover that goes over both gauges also is cracked around the area where the odo reset goes through, so will be looking at some crafty epoxy work there, while also looking for another new-to-me housing if one can be had.2 points

-

Are we talking about the oil lines that feed directly into the head as in this picture? If so, you just need a slim spanner (wrench) - not a big clunky one. If you have a cheap spanner that you don't care much for, you can grind it down till it fits. (disregard the measure tape - that was for a different purpose a while back, but it's the only pic I could find of the fitting in question)2 points

-

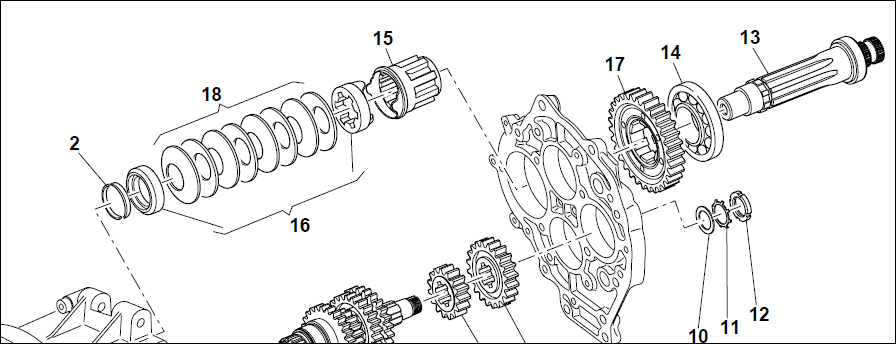

I have been reading this link closely as like KenBlake I have a 2004 Ballabio and the shifting has really detracted from the enjoyment of the bike. Lots of false neutrals and a lot of effort shifting. I am new to this bike and only have about a 1000 miles on it. My hope was to put off pulling it apart till winter. However, I found this trickle of transmission oil which looked like the area of the lever seal but turned out to be the eccentric just above it. The nut was loose and trying too tighten it was turning the eccentric which by this time was at anyones guess. I tried to tighten it figuring I had a maybe 1 in 10 shot at being close. It wasn't close and now would not go into 3rd. So I pulled it apart, adjusted it to ~0.032" at it closest point and of course changed the oil. It all seemed okay otherwise. I also cleaned and greased the shift mechanism. I only have about 30 miles on it but it is much, much better. Time will tell!2 points

-

No, the big tank was used on some flat tappet models BUT if it is plated as a '13 it should be a roller motor. For the full skinny on who, where, why and what I suggest you read my thread here. https://www.grisoghetto.com/t5879-the-definitive-guide-to-rollerisation In the tech section of the Ghetto you'll also find accurate info on other stuff that you should be aware of if considering a CARC bike. Notably things like swingarm bearing and shock linkage greasing and how to recognise if the throttlebodies have been monstered by a shaved ape. Although Griso-centric owners of all models are welcome. Some of the tech stuff is only viewable if you are registered.2 points

-

Out of the blue my beloved 2000 V11 Sport with 20k started idling at 3,000 - 4,000. Above that sputtering and stalling out. Throttle linkage closes completely. Cleaned the throttle bodies and injectors. Replaced the boots. Even though the TPS spec'd out I replaced and calibrated it. Valves are to spec. Still no love. The manual and various forums talk about software I do not posess. Does anyone know a good mechanic near Chicago? I'm shocked not be able to find one. The only dealership is new and not up to speed, Former dealerships no longer service Guzzis. Joe at The Guzzi Doctor no longer works on bikes newer than 1986. Any help would be greatly appreciated. Thanks1 point

-

It's what separates the Engineers from the "mechanics" the details. No one should be worried about this job, it's pretty straight forward.1 point

-

1 point

-

I changed my original oil tight seal when I did the gears and fitted a new one when I built the daytona engine, both are fine. You need to use an OEM Unidirectional seal on these and the rear seal or any difficult to access seal for that matter. Thats what the original factory fit seals are not bidirectional seals. Same for the gearbox output shaft seal. make sure the seal sleeve isn't damaged on the sealing face. Phil1 point

-

Makes me reluctant to tackle this gear change, seal/ gasket installation.1 point

-

High idle cam (choke) underneath throttle body hanging up? If not, a can of WD40 might be useful now. Paul B looks like pressureangle beat me to it1 point

-

My grandmother had a '82 Oldsmobile 98. After about 90k miles the rear axle started clicking annoyingly. We opened it up and had a look, found nothing. It got worse for a while, and never got better- but never failed either. The boss said, 'Sometimes you just have to let it break to see what was wrong'. My experience has shown that more than a few times over the years. My own 'Sport 5 speed had a 'pop' or 'click' in the driveshaft (I thought) so when rolling in neutral or spinning the wheel on a stand you could hear an audible noise with every driveshaft rotation. I'd had the shaft apart, everything is in fine shape. No aberrations could be felt in either the transmission or rear axle without the shaft. I disassembled the rear axle recently, looking for something. The only change I made was to replace the outside axle bearing in the gear housing. Now, the noise is gone. I can't make any sense of it, can't assign a root cause, but it's dead smooth and silent now. <shrug> If it don't matter, it don't matter.1 point

-

1 point

-

That's the one! I found something on Amazon that should do it. Thanks to all who responded.1 point

-

You can test the condensors with your DVOM ( as long as it has a capacitive function ) or an analog meter . The DVOM will give you a specific # . Usually .24mFd is a good reading . The analog meter , you will put the r reading on the highest scale and touch the leads to the case and tail of the cap . Then swap the meter leads . You will see a "kick" of the meter before it falls back to O . Do this a couple of Xs to see what you are looking for . When using this test method , ALWAYS short the lead to the case to discharge the cap. If you don't do this , sometimes you can damage the meter .1 point

-

Should have made it clearer. Problem is not the banjo, but the other end where it fits on to the cylinder head. (I have the engine on the bench)1 point

-

I if you do a search on emissions and settings on google, you will find the basic info on air/fuel ratio, timing and atmospheric conditions that effect c/o, nox and co2. Your ecu is taking several parameters and trying to adjust for performance to keep those levels in acceptable range. All ecu's react differently depending on those variables and adjust accordingly Like I listed on mine, three different ecu's three different settings. Paul B1 point

-

Agreed. I would be inclined to steer these mounts into alignment, and JBweld them to the cup. Not sure why the PO would tape off the bulb connector. Looks like you'll need a bulb socket to restore that illumination, @Gmc28 . . .1 point

-

This won't work I dont think. It states for "custom console applications only" and I think the wall thickness will be too thick to fit the std V11 console. Others may be able to confirm my thoughts. Phil1 point

-

There special tools for this Banjo. Not all engine blocks are machined the same at the banjo oil feed point and even a thin walled spanner or socket won't fit on some engines. I know because I have 4 sets of cases at home and the machining clearance for the banjo fitting is quite a bit different on a couple of them. The tool on the top LHS is one I made for removing oil pressure switches on Daytona engines. It's between a long and normal socket in length. The others are for the Banjo. Why two tools for the banjo? Because the "swing" is restricted down in the "V" and to get that last 1/2 flat rotation you sometimes need the socket. Phil1 point

-

Hi Ken, I currently have three ECU's that I've collected over the years. About six months ago after doing a complete tune on my 2000 V11 I plugged in Guzzidiag to check all the parameters. I still had a little choppy idle and found the stock ECU c/o trim set at +65. I lowered it to get the best idle at +35 and bike rode very well through all throttle inputs. When I got back from the test ride I plugged in the other two ECU's and one was at-7 the other at+15. both idled o k but not as smooth as the original. I realize that without a proper analyzer I'm just doing it by "feel" but the ride is smooth without any hiccups.. My conclusion was that there are enough differences in the ecu's to adjust them individually for your best situation. My Paul B1 point

-

1 point

-

1 point

-

I have ZERO confidence that this 'mandate' is anything more than propaganda to push the sheeple into spending money on Chinese rare earth elements, enriching world investors who own portions of mining and manufacturing in China. Does anyone really believe that Politicians can cross the world petroleum industry? I might entertain a wager that BP and Shell own significant holdings in mining and battery manufacturing in China. The economics, environmental impact, and sustainability of battery powered vehicles is plain for anyone looking or even listening. It's non-existent on all 3 fronts. Yes, electric vehicles are interesting and useful. But they are in *no way* viable on a large scale.1 point

-

[edit: This OP asked that these posts be moved to create a new thread for the issues Tunus69 is having. A few of the new posts from the old thread did not make the trip. My apologies for that. ] > As to developing a running issue after gearbox removal, it occurs to me that the main electrical ground to the back of the gearcase on the right might not be tight or is otherwise disturbed. > I expect the airbox was also removed, so the air temperature sensor connection should be checked. > Since the tank was also likely off, make sure the petcock is now turned fully on. > When the tank is replaced, the clamp for the return line to the regulator on the right side has been known to foul the TPS. Likely something simple!1 point

-

1 point

-

When I put Caruso's gears in the 'Sport, I had no leaks. I replaced the front cover seal as a matter of course. The new one leaked. I replaced the leaking black seal with a new blue one. Just got it all back together again, went out for ~100 miles to find a few drops from the front seal again. I had to replace the front seal in the '85 LM twice also. Is it the Chinese Conspiracy? Are the seals crap, or have I simply become an ape? WTF, universe?0 points

-

The difference between an Aircraft engineer and a mechanic. Phil0 points

-

0 points