Leaderboard

Popular Content

Showing content with the highest reputation on 07/25/2022 in all areas

-

Well, the latest Lucky Phil Shifter Extender job is in the books. All have been shipped and all have paid. (!) There was an overpayment or two. One grossly over paid. (!!) Gotta love Guzzi Guys. To those guys that overpaid.. don't worry, I'll put it to good use. Most likely fuel for the helicopter that I use to take out to the yacht that I bought with Extender money.. or maybe beer. Thanks all! You guys rock..2 points

-

2 points

-

Heat can't hurt(up to a point) but if it's retained by red or green Loctite then anything less than about 180-200deg C is pretty pointless as that's the temp required for it to release. Heating the head of the screw is also a bit pointless here as the loctite on the end is so far away on a long screw. Try some boiling water on the throttle body itself where the screw threads into it but I don't think it will help. BTW treat those aluminium half moon injector feed line retainers with care they are easily damaged and have been unobtainium for years. When you get them out just have them professionally done, it's very cheap and they can give you a spray pattern and flow report. Cleanings one thing but the spray pattern is important as well. I'm only making my own rig because very few places clean and flow test side flow injectors. Everyone does top feed injectors like the V11 Sport has. Phil1 point

-

On my bike the injectors were held into a plastic housing with two phillips head screws. These screws were retained with locktite. Are these the screws you are asking about? Anyway, one way to remove tight screws is to use penetrating oil and heat. Heat softens locktite. With a plastic housing, heat conduction is poor, so heating the screw head with a soldering iron may help. How hot you ask? About 60°C max should be safe. You can hold your finger on 60° for a few seconds without burning.1 point

-

I'm going to try adding some Elmer's glue to the motor oil for a couple hundred miles to see if that works1 point

-

I'll check the balance but I don't have driveability issues like when I got the bike and the TB's were way out of sync. Anyway, give me a few days. Update: OK, I couldn't wait, I ran out to the garage, put the SyncPro on the Lemans, it's all good! TB's are balanced at idle and fluid columns rise in sync as throttled up (to 4k rpm).1 point

-

Gentlemen: Thank you for the tips. I'll go through the boots and gaskets looking for an air leak. Hopefully I'll have some news in a few days.1 point

-

I thought I might let my weeping timing chest drive the decision to go in there. But it has stopped weeping . . . (for now) . . .1 point

-

It's what separates the Engineers from the "mechanics" the details. No one should be worried about this job, it's pretty straight forward.1 point

-

1 point

-

Are we talking about the oil lines that feed directly into the head as in this picture? If so, you just need a slim spanner (wrench) - not a big clunky one. If you have a cheap spanner that you don't care much for, you can grind it down till it fits. (disregard the measure tape - that was for a different purpose a while back, but it's the only pic I could find of the fitting in question)1 point

-

Whatever. Cheer up y'all. I'm sure these ladies ain't singin' our song . . .1 point

-

The only time I've seen a cap blow off (or once, tore the cap's tip open) was from throttle body imbalance . . .1 point

-

FWIW. I removed the evap can T-hoses and capped the manifold ports with high temp vacuum caps bought from McMaster-Carr. The problem with the caps is that every so often a cap would blow off during cold start cranking. To prevent the cap from blowing off I cinched the outside diameter of the cap with small gauge ss lock wire. Then over time I noticed the high temp caps discoloring from heat, I eventually removed the caps, manifold nipples and replaced nipples with screws & fiber sealing washers....it's been fine since.1 point

-

The fuel injector cleaning was/is the best $$$ ever spent . They cleaned my nozzles in an ultra-sonic cleaner flow tested them and printed off the results . YEOW ! You have to start out w/this to end up with perfection !1 point

-

After removing the cotter pin, it is necessary to remove the lower part by force. Nothing holds it in, only sealing o-rings. There is a filter, I recommend cleaning it.1 point

-

I'm building this thing for something to do. It has been enjoyable and has given me something to do.1 point

-

Yes it did Running like a champ. IDK how it ran ok for a few weeks when I first got it, but the lines were connected wrong by previous owner and I didn't have enough knowledge at time to see the problem right before my eyes.1 point

-

With fuel prices up lately in the USA, someone mentioned my bike thinking it makes impressive fuel economy. I had to admit that it is almost double that of my passenger cars, yet . . . The commute to my office in the passenger cars is 9 miles/ 15km. On the V11 Sport, the commute is 50 miles/80 km.1 point

-

Today at our LunchSpot, a fellow asked twice about the year of the Sport, then twice more about the miles. Then, there was some comment about VooDoo. I glanced at his woman, sidewise, and thought, "I don't want her knitting a yarn doll of me." Out come the red pins and, well, you know: VooDoo !1 point

-

1 point

-

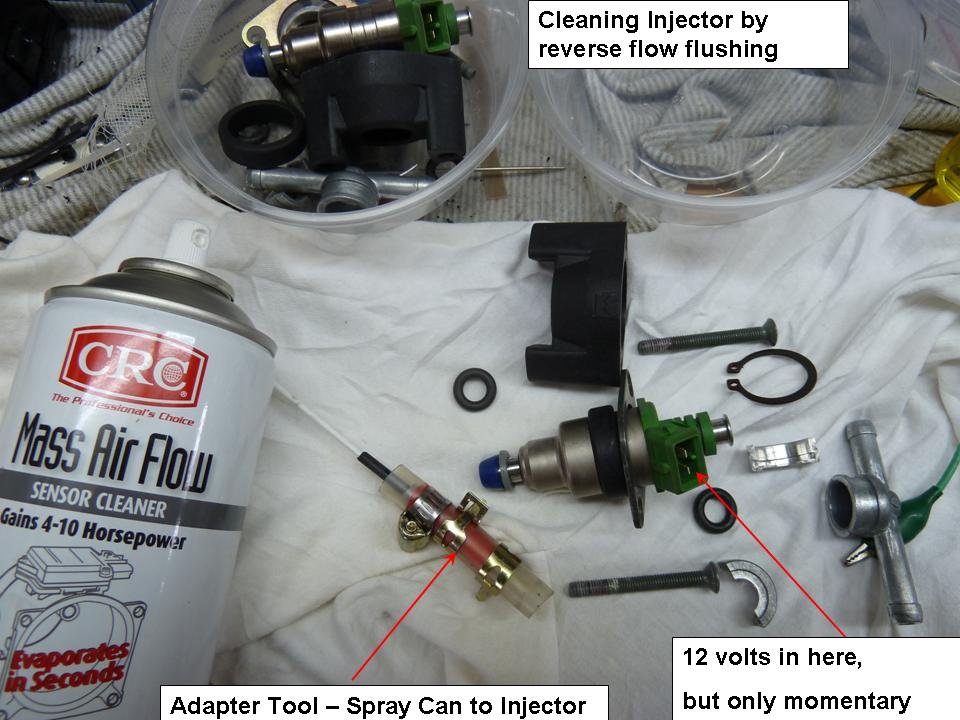

A little gizmo arrived today as part of my long and somewhat meandering process to build an injector cleaning rig. It was like $22US on ebay delivered and allows you to operated the injectors on various pulse settings while you run some cleaning fluid through them. So cheap to buy it wasn't worth messing around making up something less capable myself. The next mission is to organise a small pressurised container of about a quart of fuel/cleaning solution mix. The side flow injectors shown are a bit of a PITA to clean because you need them fitted to a throttle body to feed the cleaning solution into them. I have an old single Ducati T/B I can use for that. The top flow injectors on the V11 are far easier. Just connect a hose from the pressurised source to the injector top and have the other connector blanked off and stick the injector in a container and away you go. I'll update as I go along. Ciao1 point

-

Well I got my V11 all back together but it wont start. It cranks fine, fuel pump pressurizes, got spark but no fuel. If I squirt a little fuel into the manifold balance fittings, it fires. My diagnosis is stuck injectors, as the bike only has 5800 miles and has been sitting for a decade or more. The tank looked clean but was completely dry. My question is are there any tips for getting the injectors out? There are two flat head Allen head bolts that are extremely tight for each injector and I am afraid to put more torque on them. Or any way to un-stick them without removing them? Or is my diagnosis wrong?1 point

-

It's Alive!!! Tonight I had some time after work so I went out to the bike with my laptop and ran Guzzidiag. One of the actors is injector test for L and R. I already had the inner rubber manifolds off so I had a good view of the injector tips. I tested the injectors a couple of dozen times until I had a nice puff of fuel mist from each. At first nothing had come out. I also thoroughly flushed the fuel line and bled it from the lowest point and then at the regulator until I had a steady stream. Put it all back together and it fired first time. I wont have a chance to take it out on the road till the weekend, but I will report back again. Thanks for all the great suggestions.1 point

-

antmanbee have you got to the bottom of your problem yet? I had a similar problem when I refitted my tank recently, fuel pump made all the right sounds, just wouldn't start. I cycled the kill switch a few times every thing sounded good to go it just wouldn't fire at all. Given the fact the bike had always been a good starter even after long periods of not being used this was puzzling. I checked for spark using a spare plug, no problem there. After this I disconnected the fuel return line as recommended by MartyNZ then the obvious was plain to see, I simply had not opened the tap. Yeah I know..... Rob1 point

-

Try disconnecting the fuel hose at the regulator at the RH side of the tank. You should get a squirt of fuel out of the hose every time you turn on the key. If not, you have a supply problem. Tank valve, pump, filter, kinked hose. If you do decide to remove the injectors, you could try this: https://www.v11lemans.com/forums/index.php?showtopic=18805&page=18&do=findComment&comment=2153241 point

-

I have an identical injector cleaning kit available for loan to southern hemisphere Guzzi owners. You just need to send it back to me, or let me know who you sent it on to. Scud, the big question: did you compare spray patterns before and after reverse flushing? Those injectors can be difficult to get out, so was it all worth the trouble? I didn't think to check before I back-flushed my injectors, so I don't know. And just to confirm your Guzzi credentials, the hammer is just out of view in that picture, right? You don't want a moderator asking questions.1 point

-

0 points