Leaderboard

Popular Content

Showing content with the highest reputation on 07/18/2023 in all areas

-

5 points

-

The only country that speaks better English than the English themselves is, of course, Australia. No accent, no dialect, no slang, just perfect unadulterated English.4 points

-

It's Shakespeare docc. It means it might be a "rule" but it rarely is adhered to or used. If you are holding up the empire state building or the gas turbine on the wing of an aircraft where you want to be assured the bolt will achieve it's ultimate tensile strength if needed then it makes sense to use the same nut material. Thing is in the motorcycle world fasteners don't fail because they are subjected to loads beyond their yield strength they fail for other reasons. If you applied the female threaded component must be of the same material strength as the bolt or stud then our engines would all need to be made of steel. The torque arm bolt failures wouldn't have been due to a lack of bolt strength in shear it would have been a fatigue failure initiated by wear from the bolt being loose and or corrosion I would think. The torque arm doesn't carry a lot of load in reality. Phil3 points

-

Ok folks I finally found my electrical problem and it was probably self inflicted. After initially checking all the fuses and replacing each relay EXCEPT the START relay, I removed all of the body work and began checking each individual junction plug to include disassembling the ignition switch. When all that failed I called a friend who went thru each circuit. We then discovered at some point I must have inserted a 4 blade relay into the STARTER relay plug. This relay also supplies energy to the brake light, headlights and horn relay via the green/white wire. PROBLEM SOLVED!!!! We also learned the fuse for the fuel pump activate the starter when I discovered a brand new faulty fuse. Thanks so much to Docc and everyone, especially for posting the wire diagram!!!!!2 points

-

@Art My guess is no upgrades have been done, as many times owners don't spend the time or money. With that said, I'd adjust them to stock settings and start from there. Ride for some miles, then decide if they are too harsh, too soft, etc.2 points

-

And Guzzi content as well.....! Wonder what it'd be like with a big block motor? 1400 Cali maybe...2 points

-

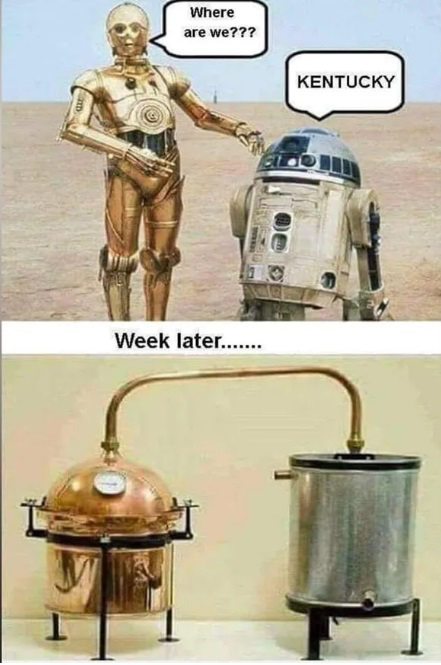

2 points

-

2 points

-

2 points

-

1 point

-

The new wheel is a 5.5 X 17 and fitted with a 180 tyre is around 6kg lighter lighter than the old 5.5 x 17 with a 170 tyre. That's with the hub drives and disks fitted. Then there is the axle and the brake bracket machining which was done for looks not weight saving. Then whatever is saved by machining off the bevel box flange maybe 150gms. 6kg is a decent weight saving swinging on the rear axle. I forgot to measure the weight saving on the front wheel and tyre assembly. Phil1 point

-

As doccs image shows the steps are normal. Makes it easier to remove and install the axle. The steps are only .5mm on the dia where there is no interface with bearings. Phil.1 point

-

You haven't seen a busy rear axle until you pull the wheel off an early carb Sport..1 point

-

Yep, normal axle steps. I replaced my axle for that reason, but wasn't necessary . . .1 point

-

Don't worry about it . You WILL know a bad axle when you see it . Also , when you slide your hand up & down the axle shaft length (while wearing a brown jersey glove) and if you feel bad spots om the show up , replace it .1 point

-

Hi Phil, Your steel axle appears like the wheel bearing had spun on it....Is that normal? My rear axle looks like that, I can feel a slight steps/ridges on mine. I attribute the wear to the misplacement of the large washer that normally goes between the rear drive and swing arm being improperly placed between the wheel external drive splines & rear drive internal drive splines. Yep, you read that right. I'm just glad I caught it before it ruined the any splines since the washer only allowed partial spline engagement. Anyway, back to the "stepped" axle....to me, it obviously looks worn due to a bearing spin. I'd like to replace the axle if I come across a good used one but haven't been successful at that yet. Maybe i should get off my wallet and buy new, if available??!! Or if you're satisfied with your engineering and make a run of axles please place me on your list of potential buyers. Thoughts? Oh, my wheel bearings feel ok and I couldn't detect any unusual wear with the bearing i.d. Art PS - Nice job on the Ti axle!1 point

-

Docc, I think he means something like "you're technically correct but meh, does it really matter?" A bit like the susceptibility of titanium to embrittlement & stress cracking when in contact with cadmium; it's true, but at normal temperatures it isn't very important.1 point

-

If I had even just one Titanium nut . . . Oh, wait, I took that "somewhere else" . . . I asked about matching the bolt and nut metals from learning that a 10.9 hardness bolt should be matched to a 10.9 hardness nut, maybe even the washer, to insure proper torque and no galling or distortion between the metals' differences.1 point

-

No never an issue. I use copper anti seize on Ti Parts but don't usually bother re applying it once it's on there and I remove and install bolts etc. Phil1 point

-

1 point

-

1 point

-

Good point on upgrading the Lambda probe! That was brought to us in 2020 by valued member @ScuRoo. Check out the good stuff he reported to us in his thread:1 point

-

1 point

-

That video is getting around fast. I just now saw it linked in the german language forum that I am involved in.1 point

-

1 point

-

G'day mate Yep I realised after I posted that Chuck's Scura has Ohlins suspenders so not relevant to our set ups. Funny though his settings aren't far off mine all the same.... Cheers1 point

-

My official Waddington Effect shakedown riding for the XIX/SSR began today after having to re-bleed the rear brake that I didn't get right the first time. Waddington was right, ya know.1 point

-

Putting "Rear drive: far right side needle cage.: on my list now. Thanks docc for the reminder. I just did brake fluid flush on my '02 clutch/brakes. The '03 is now saying "Hey, what about me!"1 point

-

Also the parts that might look ok now, but should at least be in your bin of "parts that I may need soon": > Crankcase Vent hose from bell housing to the top of the spine > Hose couplings between the throttle bodies & the intake spigots > TPS Sensor > Phase/Crank position sensor > Oil pressure Switch > The improved gearbox shifter return spring1 point

-

1 point

-

I didn't like the fact that I had more doors than anyone there & my hands would not cooperate . One thing I can say , we could have changed out wheel bearings (Kale's) , changed oil pan gaskets, clutch job , adjusted valves , synchronized TBs ,replaced swingarm bearings and just about anything else because I can do one thing right . Load a truck up for a service call ! Oh yeah , jump box , battery charger and scanner for overheating vehicles .1 point

-

1 point

-

I'm the one who brought and rode the V11 and 14 Custom. My son Gus rode the Norge and our buddy Tim rode his Harley. We packed them tight in that configuration for less wind drag at 75 mph. with 175# tongue weight. Was it overloaded, YES. Tim and Gus rode the cruisers on the way home, took off almost 2000# towing weight. SKIP1 point

-

Rick, how about this car? Old school MotorWeek Flashback video, super cool Alfa.1 point

-

1 point

-

May we all get to take our own shortcuts from Nayook to Noojee! I tried that from Dowelltown to DaleRidge on the way to this KSR and rode the worst "road" in my riding career. It was some combination of a Trials Course and a bombed-out battlefield. I ran off the "road" (just) once and only noticed as the surface improved up the local's driveway!1 point

-

This place is and has always been a god send as far as keeping these bikes on the road! Especially in the early days of ownership when having ah teething issues and getting them sorted! Even when you have it sorted it's still a bloody great place to hang out as I get the feeling we're all kinda like-minded! Anyhoo it's a credit to both Jaap and Doc and long may it continue to be such a beacon! Cheers Ps actually I see new members keep on joining so definitely doing it right....1 point

-

1 point

-

1 point

-

Quite a spread. I'd love to see the Alfa and the rug it's on. @Goofman1 point

-

Been using it for years. It's best for components that need to be removed fairly regularly, such as rocker covers, sump gaskets etc when used in conjunction with the correct gaskets. Easy to clean off too.1 point

-

ThreeBond is a brand name. I have two of their products, based on Pete Roper's recommendation. The products use 4-digit codes as product names. So my tube of ThreeBond 1211 is white, flows easily, takes several hours to cure. My tube of ThreeBond 1184 is grey and tacky and stringy, a little more challenging to apply, but cures quickly. I used it recently on my transmission pre-selector case - filled it with oil and rode it after 15 minutes. When I sealed all the cases on my Scura transmission, I used Permatex Right Stuff, which can be had in grey or black. I also have a tube of Permatex Gasket Dressing and Sealant, which is blue - and they say "compare to Hylomar Blue" on the package. I got that when I was trying to find some Hylomar gasket dressing. There is a dizzying array of sealant options. All the above I used recently seem to be improved over the red or black RTV silicones that I used a long time ago.1 point

-

You can use it on any mating sufaces you want . It is this good. You can use it with a gasket or as a lone sealant. There is an assembly procedure you must adhere to for it to be effective .1 point