Leaderboard

Popular Content

Showing content with the highest reputation on 07/19/2023 in all areas

-

Just as an update, we're evaluating the costs of restocking these plates; We had them cut at a local laser shop last time, which requires a minimum order (if the material comes in 4x8 sheets like many, that's ~36 pieces) vs. buying cut squares and machining them on our own equipment (much less up-front costs) as we can set up and run one or a hundred as required with only the raw material as overhead. It took 3 years to find homes for 50 pieces, I don't expect demand to increase so unless cost or quantity discount go down, we'll probably take route 2. That comes with a different set of problems, primarily edge finish as Stainless doesn't cut as cleanly as normal steel. Truly, sharp edges don't much matter once installed, but there can be no burrs or bits to interfere with sealing or become loose debris.5 points

-

This is a goooood time to install 5 pin relays in all ports . Glad to hear you are up n running !5 points

-

Runs strong with 94500km. Paoli handle bars, Roper plate, Jefferies ECU, Omron relays, comes with new clutch, hub,sentering tool, 5th gear repair set, V11 forks, titanium GPR exhaust +++. I better buy a lottery ticket, parts alone easy 20000kr+, everything 35000kr [emoji3]. Yes another IPA. Cheers Tom. Sent fra min SM-S906B via Tapatalk4 points

-

I had this done during my G&B Sport Monza build. Together with the light OZ wheel, it made quite a difference.4 points

-

The new wheel is a 5.5 X 17 and fitted with a 180 tyre is around 6kg lighter lighter than the old 5.5 x 17 with a 170 tyre. That's with the hub drives and disks fitted. Then there is the axle and the brake bracket machining which was done for looks not weight saving. Then whatever is saved by machining off the bevel box flange maybe 150gms. 6kg is a decent weight saving swinging on the rear axle. I forgot to measure the weight saving on the front wheel and tyre assembly. Phil3 points

-

Quite. Unless they ingest some horrible shite why would they wear out? They're probably the best lubricated thing in a motor!2 points

-

1 point

-

Nothing wrong with having that rebuild kit in your spares pile. Glad to hear you are back in the saddle!1 point

-

1 point

-

The kit arrived but I decided to give it one more shot before the M/C rebuild. I bought a cheap Harbor Freight brake bleeder vacuum. Success in about 6 minutes! I Guess I needed to spend unnecessary money and waste a bunch of time like usual. With the benefit of hindsight, I'm glad I didn't burn the garage down. Thanks Doc1 point

-

1 point

-

Yeah, much simpler to only use the 5 pin relays. That way all relays are interchangeable, and if you carry a spare or two you know it will work in any position.1 point

-

1 point

-

As doccs image shows the steps are normal. Makes it easier to remove and install the axle. The steps are only .5mm on the dia where there is no interface with bearings. Phil.1 point

-

Ok folks I finally found my electrical problem and it was probably self inflicted. After initially checking all the fuses and replacing each relay EXCEPT the START relay, I removed all of the body work and began checking each individual junction plug to include disassembling the ignition switch. When all that failed I called a friend who went thru each circuit. We then discovered at some point I must have inserted a 4 blade relay into the STARTER relay plug. This relay also supplies energy to the brake light, headlights and horn relay via the green/white wire. PROBLEM SOLVED!!!! We also learned the fuse for the fuel pump activate the starter when I discovered a brand new faulty fuse. Thanks so much to Docc and everyone, especially for posting the wire diagram!!!!!1 point

-

The only country that speaks better English than the English themselves is, of course, Australia. No accent, no dialect, no slang, just perfect unadulterated English.1 point

-

1 point

-

That was shocking noise, wasn't it @kalev11 ? Apparently, the dramatically mis-set TPS caused such running imbalance at idle that the cylinder firing combined with the wear of my flywheel to sound like nine monkeys fighting their way out of a steel barrel with ball pien hammers . . .1 point

-

I have Penrite Pro Gear 75W-90 in my gearbox. No oil mist. The troublesome vent hose can split at the outlet on top of the bell housing, which lets oil vapor into the clutch area. When I bought my bike, it came with an oil drip at the witness hole at the bottom of the bell housing. Replacing the vent hose fixed the leak, but I couldn't see the cracks in the hose until I took it out. I have a part used bottle of Shockproof Heavy with about 750ml still in it, not quite enough for a gearbox. I bought it from Brake n Transmissions BNT1 point

-

I have seen less than four oil pump problems im 50 yrs of tinkering w/things. Historically , oil filters n o-rings are at the top of the list .1 point

-

Well G-I-V , what did you find out ?1 point

-

1 point

-

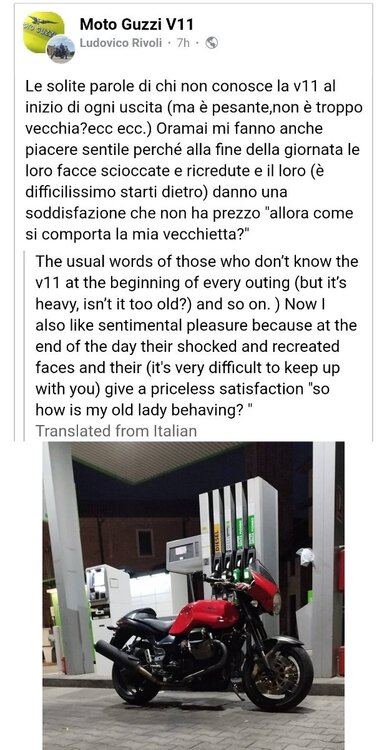

The photo was pretty dark which made it more difficult. And that red is a tough color to match on a good day. But this should be close:1 point

.thumb.jpg.6ca2ad474f505dd9ad78d32a82ac6c8a.jpg)