-

Posts

988 -

Joined

-

Last visited

-

Days Won

43

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by MartyNZ

-

No change. The Air France plane had an autopilot disconnect in cruise as it got extreme icing in a super cell. The crew must have been half asleep, and stalled it all the way into the sea. Loss of situational awareness. The pitot icing was gone in seconds, and just re-engaging the autopilot would have saved them. Sorry Chuck, didn't mean to hijack the posting from a Weather God.

-

Nah mate, remember that commercial aircraft are flying on autopilot most of the time. Then airline procedure demands that only one pilot is flying if flying manually. On an Airbus, if both sidesticks are used at the same time, the inputs are algebraically added (with limits), just the same as manual inputs to B737 control wheels, except digitally instead of hand force. If both sidesticks are used, two SIDE STICK PRIORITY lights on the glareshield come on, a loud "DUAL INPUT" message is played every 5 sec, and a post flight report goes back to the airline. Not only can both pilots see each other's sidesticks, three computers are monitoring as well. The pilot can't hide on a modern aircraft.

-

When I was a young apprentice, I "salvaged" a 25litre drum of 100/130 (green Avgas) from a DC3 going into maintenance, and put it in my Honda CB450. It felt faster, so I tested it. It reached 1000rpm more in top gear at the bend on Harewood Road on 100/130 than the "96 Super" of the time. I previously thought that higher octane was only worthwhile with higher compression or a blower, but there it was going faster. Obviously there was some other difference than just octane rating for this fuel to give noticably more power. I had just fitted new 1st oversize pistons and rings, and XS650 cans, but otherwise the 450 was standard. I know that Avgas has less volatiles to avoid boil-off and vapor lock at altitude, and I assume higher calorific value ingredients which made such a noticable difference. Note that avgas is not the same as 100 octane service station pump fuel. As for using 100/130 Avgas in a V11, I agree with the comments that the TEL additive, even in the LL (low lead) variant, will harm a catalytic converter and oxygen sensor if fitted. If not fitted, no harm to the engine, and possibly more power.

-

I suspect that a new V11 did not have a 3k snort. @docc do you remember? I believe that you should complete Docc's tune-up guide first before tweaking the ECU. TPS setting, timing sensor gap, cylinder synchronization, and slightly looser than book valve clearances are important. Decent Tune-up - How to... - Moto Guzzi V11LeMans.com Forum Also look for signs of a worn timing chain tensioner affecting ignition timing. Point a timing light into the porthole in the bellhousing and watch for erratic movement of the timing mark at various revs.

-

While the sideplate is off, you could burnish the edges of the cam tracks in the cam wheels. I think Pete Roper suggested this. Then I shimmed the cam wheels inwards to maximize engagement with the shift fork pegs.

-

Tim, I fitted three pairs of drilled pucks in alternating recesses. See picture. No problems after 3 years. The other 3 pairs I sent to you in 2017/2018. Yours have slightly less rubber removed.

-

Drilling the cush rubbers was Greg Field's idea. I tried it, and never went back. Making a Cushier Cush Drive - Technical Topics - Moto Guzzi V11LeMans.com Forum There are 3 places that need lubrication while you have the drive plate off. The input spline to the wheel benefits from Kluber Staburags NBU 30 PTM grease, the rubber pucks and retainer plate spacer benefit from dry-lube spray, and the drive plate bore needs waterproof grease. Should I lubricate my rubbers? - Technical Topics - Moto Guzzi V11LeMans.com Forum More discussion here: Cush drive lubrication - Technical Topics - Moto Guzzi V11LeMans.com Forum

-

Possibly that weld can be as good as the original material, but not stronger. Because the weld attaches to original material, strength is limited by that. The weld looks good, but a strong weld depends on lots of things. Paint & oil contamination, incomplete weld penetration, porosity, and variations in any residual heat treatment all make restoration of strength difficult. But if it was me, and since the plate looks like the improved version, I'd leave it there. Watch for oil weeping through the weld after a long run.

-

I had to look up what a W123 was, and yes, now you mention it, there's a lot of them on the road in NZ. MB seems okay, but many recent models of European cars don't seem to age well. Great when new... The Volvo is an obvious exception. Great cars, similar reliability and durability to Japanese and Korean cars.

-

There's some discussion here that might help you. https://www.guzzitech.com/forums/threads/bike-wont-start-dsb07-dsb08.2717/

-

Is Throttle Rotation Necessary For Cold Starts?

MartyNZ replied to guzziart's topic in Technical Topics

Art, my bike needed a twist to start, just as you described. It came alive with a Ba-boom to wake the neighbors. I always felt bad about getting rpm above idle with low oil pressure. Then I loaded Meinolf's BIN file to the ECU. After that it starts and idles without touching the throttle. -

Anybody know which ports on the broad sump to the cooler is which?

MartyNZ replied to Weegie's topic in Technical Topics

As Tom suggests, a bike without a temp indicator is normal. You know what your oil temp is and it bothers you. Maybe you actually don't have a problem. Engine oil needs to get up to 100°C before water condensation evaporates. Cheap oils can tolerate 150°C without degradation, and Group 3 & 4 PAO/Ester oils handle over 200°C. Some engine oil additives don't work until the engine is up to temp. Hot is good -

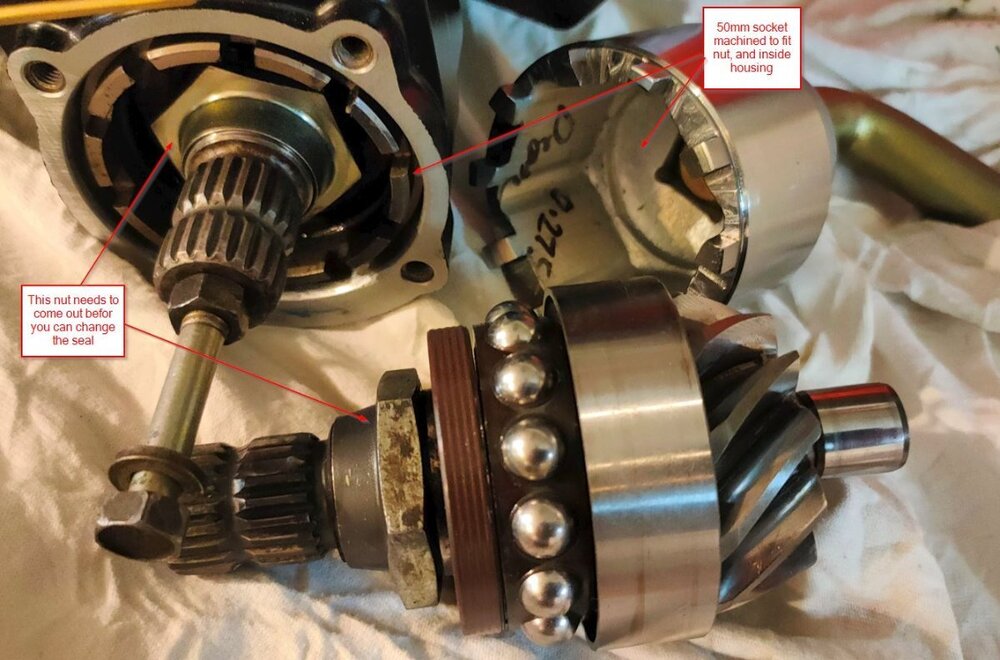

I made a ring-nut socket from a 50mm hex socket. But first, channeling my Father "if it isn't broken, don't fix it". I think you should only remove the pinion if you must change a leaky seal on the pinion shaft. Anyway, you would need to remove the #13 nut, as the seal is behind it. I used a hot air gun and heated the housing around the pinion bearing to 100°C. Nut #18 undoes easily then, and a gentle biff with a slide hammer and the pinion assembly will pull out. 100°C is safe for the seals and O-rings, but don't get much above 120ish°C. If you don't have a IR heat sensor, then a temp where you can touch the housing but can't hold your hand on it for a second is about right. Nut #13 is staked into a slot, and is tight. I drilled and split the old nut, but then of course I needed a new nut... and a shaped wood set of vice jaws to grip the pinion gear to tighten it back up. Lots of swarf spiraled off the outer end of the nut as I tightened it, so good cleaning is needed.

-

Docc's second suggestion is the worst news, but is actually more likely. if the RH end of the crown wheel has rust pits on it, then the #10 seal needs to be replaced, after you blend out the rust (if minor) or fit a seal saver (if rust will chew out the new seal). Be aware of the seal orientation. It looks to be in backwards when correctly fitted. A leaky #10 seal allows oil to travel along the axle cavity inside the crown wheel, and the leak shows coming out the LH side of the box.

-

You should put the sensor back on the airbox where it was designed to be.

-

The air intake temp sensor should be in a position to measure the air going into the air filter. https://www.v11lemans.com/forums/index.php?/topic/19764-hey-you-guys-with-air-pods-and-ecus/#elControls_216472_menu DD mounted a sensor I made for him above the rear shock. Pictures and ride report here: https://www.v11lemans.com/forums/index.php?/topic/19831-air-temp-mod-for-no-air-box/ The longer sensor is just the equivalent thermistor wired to an extended loom, with the last 100mm or so stiffened with a 3mm steel welding rod, covered with heat shrink. https://www.v11lemans.com/forums/index.php?/topic/20032-pods-what-size/&do=findComment&comment=222872

-

I stopped buying Castrol when they started advertising Syntec as "full synthetic" despite the fact that it was made from a Group III mineral base oil. Because of Castrol, nowadays the advertising term "synthetic" applies to any mineral oil with extra processing and a higher price tag. All the manufacturers now sell a "synthetic" Group III mineral base oil. True synthetic oils are Group IV base oils made of polyalphaolefins (PAO) or Group V base oils made from esters (or other synthetic chemicals). I use an Australian oil in my air-cooled bike that is a mix of Group IV & V. I try to avoid products from manufacturers who imply lies in their advertising.

-

A flatmate years ago always wanted to mow the lawn when we had two stroke mower fuel mixed with Castrol R. It had an awesome smell. https://www.motorsportmagazine.com/archive/article/july-2000/55/castrol-r The storybook hero WW1 flying ace "Biggles" had to wipe castor oil off his goggles when flying his Sopwith Camel.

-

Ha, reminds me of an experiment I did as a school kid. I thought the nitrobenzene was related to tri-nitro-toluene (TNT), so I mixed up a batch of nitrobenzene in the chemistry lab, and poured it into the fuel tank of the big old Dennis school lawn mower. I watched the mowing for a long time before I realized I wasn't going to see anything exciting.

-

No problem Weegie, I was just surprised by how easy it was to pump oil through the oil pump.

-

Dunking them in boiling water, and using a smear of oil makes things easier. I think there is an order of left or right first that works best too.

-

How about this thing to beat the paint off your top fork yoke? Join the clan! PORTACHIAVI "THE CLAN" ORIGINALE MOTO GUZZI (motoitalia.it)

-

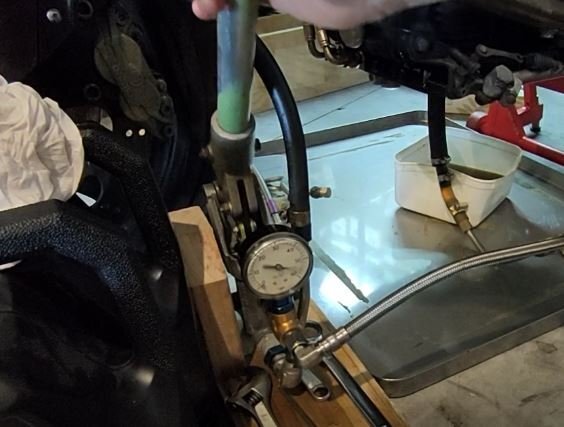

Using a hand pump, I could easily exceed the gauge range limit of 60psi, and, after 20 seconds got oil dribbling down from above. I don't have any concerns now about oil pressure. Thanks for the advice and comments. Helical gears explain why I could force oil past the main oil pump. Now I should be able to use that little hand pump to test a pressure regulator.

-

I did find a conductive resin (I know, too much junk lying about) and it was very conductive. The uncured "part A" measured at 2Ω over 10mm in a smear left in the lid. Nice, but I can't think of a use for it in my bike. It does tell me that a conductive paste is possible, but it would be bad in an ignition switch.