-

Posts

975 -

Joined

-

Last visited

-

Days Won

43

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by MartyNZ

-

It's a good time to repaint the tube and clamping block while it is apart, to repair the road grit damage caused by that inadequate front guard.

-

Yes, the damper is repairable. A visit to the local seal shop is needed, then fill with ATF fluid. My damper is always on the lowest setting, so you may not need it on the long frame bike.

-

Any guesses which port on this air-cooled cylinder head is the exhaust port? Once water cooling is introduced, the exhaust port orientation becomes less important

-

My airbox is off at the moment, so I took a look. The hex head bolts holding the airbox lid down are 6mm dia x1mm pitch, length 82 & 30mm from under head to end. The screws attaching the side panels to the airbox are button head chrome or SS 5 x 0.8mm 12 mm length. The brass nipple is for the engine breather hose from the banjo at the top of the spine. Any oil resistant low pressure hose will keep oil vapour from making a mess. There should be an air temperature sensor on the front of the airbox. If it's not there, the ECU will assume a default temp, and the engine will be out of tune if the air temperature is not 20°C. The 2 screws on the rear of the airbox attach angle brackets going to frame mounts. You need those. The engine is sensitive to air leaks, so replace the cracked intake boots. The designer took some trouble to optimise the intake system, and you are restoring to that. Expect the engine to run better over the rev range, and with proper air filtration, when you finish.

-

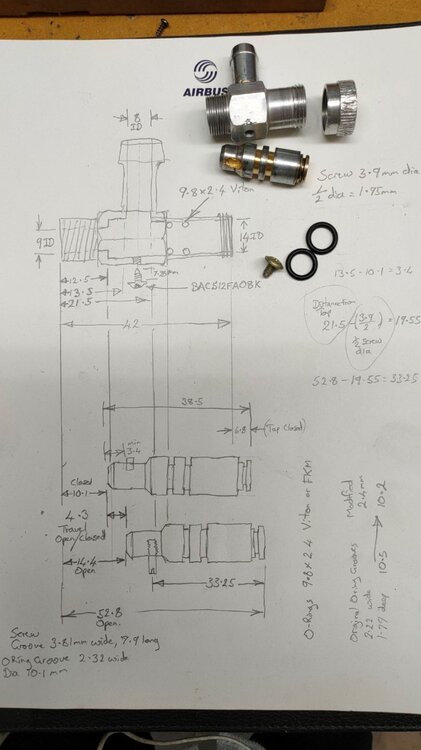

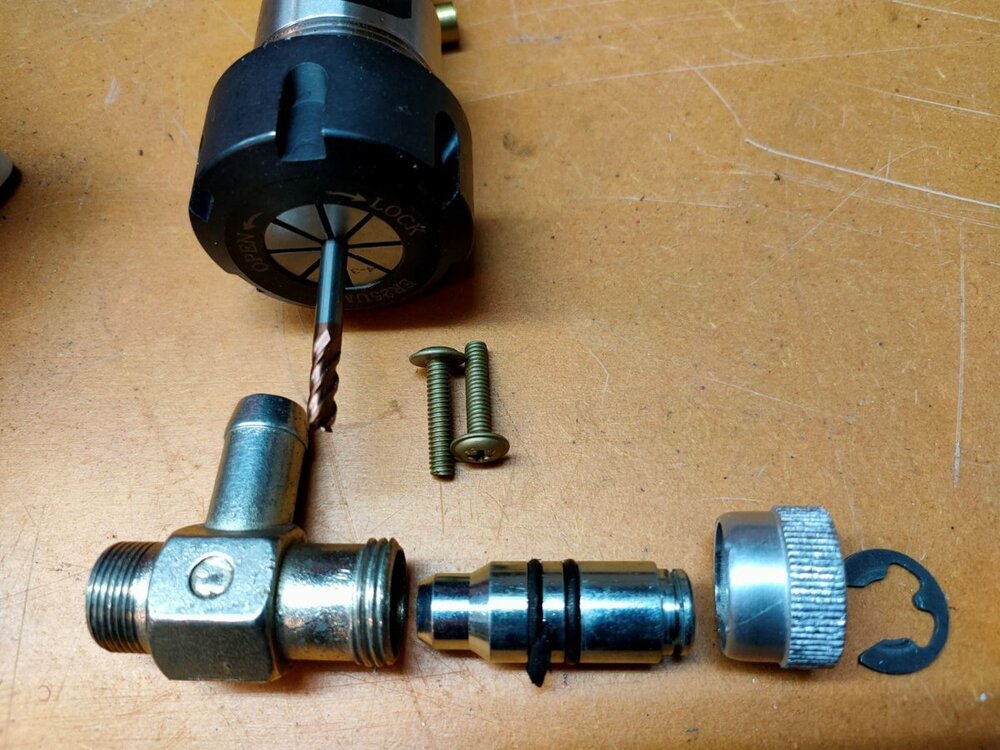

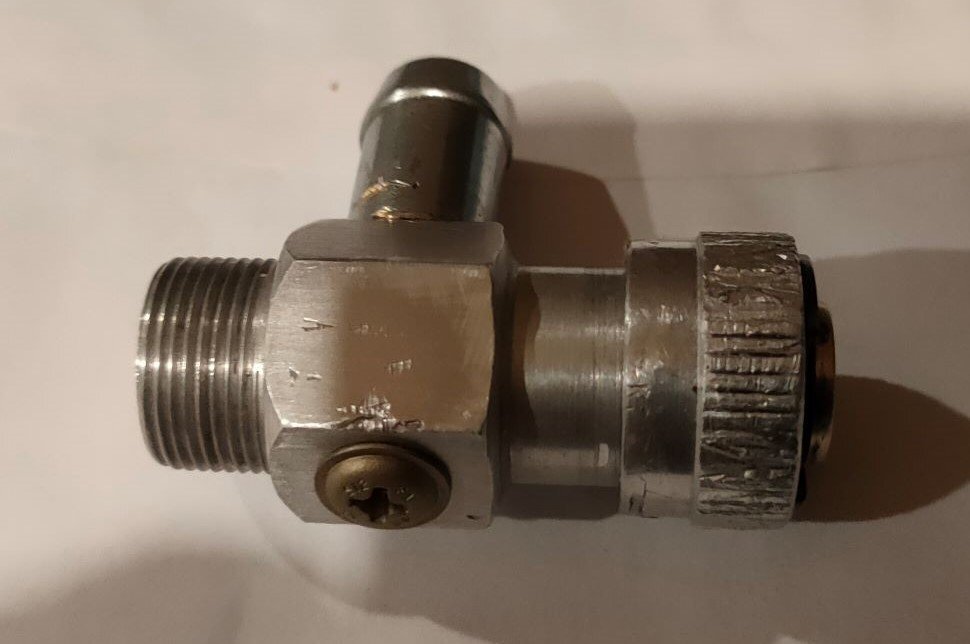

I followed @Lucky Phil's experience and advice and fixed 1 leaking tap. 2 more to go. Steps are: enlarge the O-ring grooves, machine an anti-rotation slot in the plunger, adapt screw to make an anti-rotation pin, tap a hole to the valve body, fit bronze anti-friction washers on each side of the knob, put sealant under the anti-rotation pin, assemble with fuel resistant grease. @cash1000 tells me that his modified tap is easy to open/close, and it doesn't leak.

-

Just out of curiosity, does that top cylinder interfere with your view of the airstrip on approach?

-

Have you read all the posts on this site that use the words "Startus Interuptus"?

-

Relays front to back: 1. START (5 Pin Relay) 2. LIGHTS (4 Pin Relay. 5 Pin OK) 3. NEUTRAL/SIDESTAND (4 Pin Relay. 5 Pin OK) 4. ECU (4 Pin Relay. 5 Pin OK) 5. FUEL/COIL/INJECTION (4 Pin Relay. 5 Pin OK)

-

You can save your original BIN file off the ECU using the reader. Saving takes about 15 minutes. Then you can load the Meinolf BIN. Loading takes about 10 seconds. Ride and decide yeah/no. Revert by loading the original BIN, or keep, it's a no-risk choice.

-

I wonder if washing the seal in hot water and detergent, then drying for a day or two, would let it shrink back to normal.

-

If you mean the ignition switch, then dielectric grease would work, but it is best used in static connections to keep water and oxygen out. I have had good results doing general cleaning/lubrication of switchgear using automotive electrical switch grease: Lubriplate DS-ES, but any white lithium grease is good. https://www.lubriplate.com/Products/Grease/Multi-Purpose-Greases/DS-ES/DS-ES/DS-ES,-1-75-OZ-TUBE/ I use dielectric grease on all exposed electrical connections. It is particularly good on ignition coil connections, but I have heard that it is bad in vented relays, where it can mess with contact resistance when contact sparking happens.

-

You mean @p6x I think. However, it is a Song Chan 871-1C-C-R1 made in China. I don't have any experience with them, but they seem to be readily available. 871-1C-C-R1-U01-12VDC-Song-Chuan.pdf

-

The relay bases have dovetail grooves to link each base to the next. You should be able to hook the bases together to align them by sliding vertically. Then you need another mount bolt as shown by P6x.

-

ANSWERED How many high milage bikes are out there?

MartyNZ replied to Art's topic in Technical Topics

Also the parts that might look ok now, but should at least be in your bin of "parts that I may need soon": > Crankcase Vent hose from bell housing to the top of the spine > Hose couplings between the throttle bodies & the intake spigots > TPS Sensor > Phase/Crank position sensor > Oil pressure Switch > The improved gearbox shifter return spring -

The piston rod can fall out, but if no brake fluid follows, then just put it back. If fluid comes out then you have a different problem

-

I can pry the forward UJ through openings in the shield, to pull the gbox shaft in and out almost 2mm. It needs a lot more than hand pressure. I expect that all the suspension movement that loads the driveshaft in rapid compression/tension is all taken by the sliding joint in the middle of the shaft. It would be a disaster if the gearbox is exposed to suspension movement. I'm going to give all 3 nipples another squirt of grease to make sure.

-

It is a good idea to replace nylock nuts after use if in a critical application, but there is an alternative. A check for "Run On" torque can tell you if the nut locking function is still effective. I'd call my Rear Axle nut critical, and the locking is a bit marginal, so one day...

-

See repair/overhaul advice here: http://www.largiader.com/tech/valeo/ http://bmwmotorcycletech.info/boschvaleostarter.htm http://advrider.com/index.php?threads/valeo-starter-refresh.954653/ You could also search this site for "valeo". You will be going down a well trodden path

-

I expect that a gearbox from a crashed bike could be cracked if the engine got a smack from the front.

-

I opened my TPS, and cleaned the inside with IPA. I reassembled it with a smear of lightweight white lithium grease. It was slightly better, but not really worth the effort. The contact wipers wear the resistor film, and nothing can save or restore that. I bought a new TPS.

-

Share your lithium battery experience; cold environment, durability, else?

MartyNZ replied to p6x's topic in Technical Topics

To be fair, a record cold temp at my place is only -8, and even so I'm too soft to ride in freezing weather. The bike alternator keeps the battery charged. The picture shows that the battery needs 20mm packing on each side to stop it rattling about. -

Share your lithium battery experience; cold environment, durability, else?

MartyNZ replied to p6x's topic in Technical Topics

I have a Shorai lithium battery in my bike. LiFePO4 (Lithium Iron Phosphate) is the most stable and least likely to catch fire of all the battery technologies. For cold starting, I have never noticed any problem, but Shorai says: "If starting at 5°C, headlights on for 30 seconds will help wake the battery and increase cranking performance. If at -17°C (1°F), leave the lights on for 4~5 minutes before cranking. The result will be a better first crank, and longer battery life. If the engine fails to start on first crank, that first crank has warmed the battery, and the second attempt will be much stronger." I've been told that it needs a "balance charge" once a year or so. It comes with a dedicated charger that plugs into a tiny 5 pin socket and manages the voltage of each cell. The charger also has a "storage" button that holds the battery at 70% for longer shelf life. The Shorai LFX21L6-BS12 cranks my V11 well after 7 years. LiFePO4 is also in my electric car, but outside temperature is not an issue as it has a liquid battery temperature management system. -

Did you disconnect the link rod between the two throttles? The rod-end on the RH side just pops down and off. Check to make sure that the idle-up cam under the RH throttle is not holding the valve open. Then you can make sure that the RH stop screw is backed off enough to allow the throttle valve to close completely. A feeler gauge helps here, as it's tricky to see. Then you can adjust the TPS to 157mV. Patience is needed as the voltage can change as you tighten the screws. Then you can reconnect the link, set the idle speed, and cylinder synch. A lot of messing around before and after this critical adjustment, but it's worth it.

-

https://www.v11lemans.com/forums/topic/21701-ecu-bin-maps/