Miro Kacur

Members-

Posts

13 -

Joined

-

Last visited

Profile Information

-

Location

Slovakia

-

My bike(s)

V11 Ballabio 2004

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Miro Kacur's Achievements

Rookie (1/5)

13

Reputation

-

So in other words, I cannot rely on GuzziDiag mV reading when physically adjusting the TPS ? I was getting +8mV higher reading on GuzziDiag vs the voltmeter (521 mV voltmeter / 529mV GuzziDiag) The question is, which of these two instruments should be taken into account the GuzziDiag (v0.60) reading or the voltmeter ? Thank you for clarifing.

-

You are right. That means I might have to rely on my gut feeling in this case. That is unless someone will clarify his/her experience on this topic.

-

Anybody please know the torque setting for those big lock nuts that go onto the pivot bolts. You know, those lock nuts that tighten the pivot bolts to pork chops... Thanks a lot!

-

This might seem obvious to many. When I was reassembling the swing arm into the frame I found useful to put a wooden stick thru the frame hole and swing arm pivot hole on one side – to align them as much as possible (please see the picture). Then I was able to correctly screw in the pivot bolt on the opposite side more easily. Of course, I had the swing arm top section already attached and fixed to the shock absorber.

-

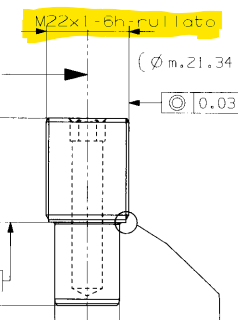

Dear All, I got a reply from Piaggo regarding this and the thread for the pivot pin is M22x1 with 6h tolerance - please see the drawing attached. So I am assuming that the correct tap for recutting the female thread in the pork chop hole would be M22x1mm 6H (Metric Fine Thread) Miro

-

Thank you Marty, Just for the clarity, here I found a similar thread in this topic: https://wildguzzi.com/forum/index.php?topic=104932.0;prev_next=prev#new

-

Hello everyone, While installing the pivot pins I have accidentally cross threaded the left one. In my opinion it’s nothing major, only the first two threads are affected however it is enough to prevent the pivot pin to line up and to easily screw in. (please see the pictures included, the damaged thread is at about 6 o’clock in the very entry to the hole) I am thinking about rethreading the pivot hole from the inside with a relevant threading bit. Does anyone have experience with repairing the swing arm pork chop pivot holes? I am assuming it’s M22x1 of metric fine thread – but I will gauge it properly of course. I am expecting to screw in the threading bit from the inside, where the threads are ok. This way the threading bit will line up with the existing threads and it will probably go thru easily for about 95% of the hole length. Only then it will hit the damaged threads and cut thru them. So much for the theory 😊 Anybody attempted to rethread these swing arm pivot holes? Thanks for your advice/opinion.

-

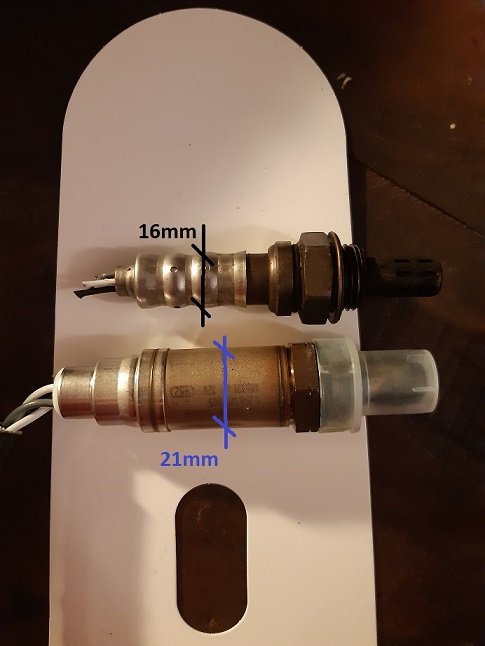

Dear All, After weighing all the options I found the most feasible solution to replace the faulty stock O2 sensor with the BOSCH Type LSH 24, LS 6206, part.no 0258006206, length 325 mm The „collar“ of the above mentioned sensor is 18mm which is slightly wider than the original stock sensor’s 16mm (for full details see my post from Sep 2 above), nevertheless, it fits in the place. I don’t have any info about actual performance because I need to reassemble the rear drive, put the wheel back, etc… So to recap -> if you are to replace your stock O2 sensor on V11 Ballabio 2004 (in the post above I have wrongly stated that I have Ballabio 2003, but in fact I have 2004) with stock cross-over, you might have to opt for the BOSCH Type LSH 24, LS 6206, part.no 0258006206, length 325 mm which is the one that can fit in the tight space and does not interfere with the engine block frame. Miro

-

Thanks, I will evaluate the options and let you all know which one worked out for me

-

Hello ScuRoo, were you able to fit the Bosch LSH24 0258003805 sensor in place of the original O2 sensor? I have a problem with the diameter of the Bosch sensor collar, it is pushing against the frame in place where the original O2 sensor was ok. Please see my reply to the topic at the end of this thread – there are pics explaining the issue. Thanks for advice

-

Hi all, What is your experience in fitting the Bosch LSH24 0258003805 sensor in place of the original O2 sensor? I have a 2003 Ballabio with closed loop O2 sensor and original exhaust. I have discovered that the original O2 sensor was faulty so I am in the process of replacement. I was following the recommendations of ScuRoo here on this thread I acquired the Bosch LSH24 0258003805 sensor, however, the Bosch LSH24 sensor has slighly wider collar and I am not sure if it fits in the exhaust hole. The collar is simply too wide in diameter and is pushing against the frame bar. Please see the pictures for better explanation. The original O2 sensor collar is 16 mm in diameter and the Bosch LSH24 0258003805 sensor is 21 mm. Anybody experiencing the same problem and if so what was your remedy?

-

Thanks Kiwi_Roy, I have made my own marks on the joints. Along the way, I have also marked many fasteners just in case that I wasn't able to find out the correct torque settings, I could just tighten them to their original position.

-

Hello there, Being a new here, let me start by thanking you for this and many other threads I have been consuming on this forum. I have followed your instructions and decided to take off the whole swing arm, just to grease the drive shaft. No problem with that whatsoever. After inspecting the drive shaft I have notices small flakes of paint peeling off (pics included). Nothing major, but still, me being a detailist, I would like to treat, just to have a peace of mind. I don’t think I need to go as far ar coating the whole drive shaft. I was thinking about applying a small amount of coat only locally where needed. Have you treated the shaft (or maybe other parts such as frame, et al) with locally applied paint and if so, what paint did you get the best results with? (If this topic belongs to other thread, I will be happy to remove it from here) Thanks in advance. Miro