-

Posts

4,482 -

Joined

-

Last visited

-

Days Won

21

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by al_roethlisberger

-

...hrmm, I wonder how much that spec above about "3 Bar" matters, and what it references exactly? The reason I ask is that after talking to the folks down at Evoluzione a while back about their kit to make the fuel-pressure regulator adjustable, they recommended bumping the fuel-pressure up to about 3.5 Bar(~50psi) over the stock 3 Bar(~45psi) once one increases intake or exhaust capacity/flow significantly. I had read this somewhere else before as well. So, I have a 3.5 Bar pressure regulator I am about to install, and wonder if the spec above means that the injectors aren't rated for over 3 Bar? I'd hate to "blow them out"... although Evoluzione has had their pressure cranked up on their Tenni for a long time, so maybe it's fine... al

-

There was a discussion on either Wildguzzi or MGCL regarding FBF cross-overs cracking, but I'm not certain if it was the cross-overs for the cruisers and/or for the V11 Sport models I know that doesn't help much ...but you might post the same question there to see if anyone has any experience. I do know that the cross-over for the cruisers, which is more of an "H" pipe design, does seem to have an awful lot of welds, which isn't reassuring al

-

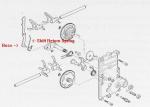

Moto Guzzi V11 Sport/LeMans Transmission Shift Pawl Failure FAQ **************************************************** Introduction: ------------------ Many owners of V11 Sports and LeMans have experienced a failure of the shift mechanism where the transimission will no longer shift out of the current gear, often 2nd or 3rd. Upon inspection, the cause is found to be the "shift pawl return spring" breaking where it makes a tight 90-degree bend. For many owners, this has been happening around a 5k mile interval regularly, and often happens again with factory replacement parts. At this time Moto Guzzi has not addressed this problem, although there have been rumors of an official updated part that have yet to be verified. However, after investigation by several other owners, looking into spring design and linkages within the transmission, it now appears that the culprit is not the spring itself. It appears that a manufacturing lot of shift linkages with 16.5mm diameter spring bosses, instead of the prescribed 15mm, were delivered to Moto Guzzi, and installed on primarily 2002 V11 Sports/LeMans, but may show up on a few earlier and later bikes. This outsized boss causes the shift return spring to bind and not cleanly rotate around it's shaft, reaching coil bind, and putting undue stress on the tab at the end of the spring itself. Over time, this stress causes the spring to break. The solution is to either replace the shift arm link with one using the correct 15mm diameter boss, or grind down the boss on a defective unit to the correct size. Sources for alternative springs as listed below are still relevant, as supplies from Moto Guzzi can be time consuming to source, however the root cause seems to not be defective spring materials or manufacture, but the boss on this shift linkage. As of April, 2005, Moto Guzzi issued the following Technical Bulletin, which confirms that the oversized boss is the problem: Part nos: 04 23 51 01 for the new arm, 04 23 83 00 for the OEM spring. However, be aware: Listed below are URLs and contact information for general information and several online discussions. Information: ---------------- A purportedly improved aftermarket spring is available from: Bonnie at (405)524 7223 - Request a "Moto Guzzi shifter spring." Cost is $12.50USD Hank Blackstock's Replacement Springs(Same as above) Project to special order a complete set of custom made springs V11 Forum Topics: ------------------------- Spring Failure and Boss Diameter Detailed - With Photos Spring Boss Diameter Issue - Final Solution Transmission Shift Pawl Spring Failure Gearbox Spring Thread with Schematic Transmission Shift Spring Failure (more) Detailed Disassembly Photos FAQ Administrative Contact: -------------------------------------- Please feel free to contact this FAQ's administrator via email or a Forum Private Message to submit new information or suggest corrections. Al Roethlisberger

-

So, which spring are we talking about having failed on everyone, the one on the far left or right of the diagram? They both appear to have a worrisome 90-degree bend. al

-

Whoo-hoo.... so my more intuition and less scientific results of moving the pump above the spine seems to have been verified as having a positive effect Thanks for the objective and very detailed testing Gio! Awesome al

-

Just ordered two from Bonnie "just in case".... She was laughing that apparently this thread has really piqued interest, as she's sold a bunch recently, where she hadn't sold any for a long time. She says their springs are made from a slightly larger material, and modified a bit. And although so far they seem to be working fine, they suspect that the fundamental design of the spring lends to their eventual breakage, so even theirs may break eventually at the bend al

-

I'll have to head home and check the "chassis number", but does this relate to the engine number? I do have that handy. - Engine Number: KR 015765 Whaddya think, am I "in" or "out" BTW, do we have a Service Bulletin or Recall # to reference? al

-

...or for the super "anal".... you could get one of those cool GPS mounts, and permanently mount your TwinMax and it's two hoses at the handlebar, with a remote TB balance cable/drive so you could adjust TB balance on the fly al

-

....no one doubted you, we just asked if you had more info as it's hard to follow-up with so little to go on from the initial post But yes, thanks al

-

.... eeeeeeeeeenteresting. Do you have a Service Bulletin # or Recall # to reference so I can call Moto Italiano with that? It would make it much easier for them to cross-reference to check my bike's status. If there is a connectiing rod issue, maybe I will just go for the Carillo rods and see if they'll credit me something... Thanks al

-

I have also heard that applying white(or similarly bright colored) fingernail polish is a good way to mark the high/low points on any of the dipsticks, stock or aftermarket. I also have the "thermometer" dipstick, which honestly is more show than utility ....but hey, I like it... anyway, I scored the high/low marks with a pipe cutter(very very lightly) but it's still hard to read sometimes. I may clean it and apply the nail-polish as well. Posts to that effect on MGCL seem to think it's a safe method, as no one has had the polish come off, or cause a problem al

-

....so I wonder what NAPA managed to do to the injectors?? al

-

....right, if MI actually made a custom map for the bike, they would have run it on a Dyno with the Dyno Tuning Link software to make the custom map for the PCIII. This usually runs about $300 and takes 45min or so. Just for clarification: are you sure they didn't provide you with a generic "custom map" designed for any bike with similar modifications? ....one they had handy, or perhaps downloaded from Dyno or Guzzitech? This is very common, and a workable solution if a Dyno tuning center is not available. The reason I ask is that I didn't think that there was a Dynojet certified tuning center in your immediate area. I could have sworn Jason was complaining about this some time back They should have provided you with a before and after Dyno run and graph, peak HP and Torque numbers, as well as the map itself on a floppy(or emailed to you). If not, and it wasn't run on a Dyno, then you unfortunately don't have a true custom map for your bike. If not, I suspect they just installed a close "custom" map saved from past customers with similar setups, or downloaded from Guzzitech/Dyno. And if so, that's not a bad thing BTW. A good close map downloaded from the Internet may work well. But it's always best, but more expensive of course, to get a map made just for your bike and it's own peculiarities. Since you have some unique items like your "bow wow" filters, a truly custom map may make some positive impact over the generic "custom" map you may have. Anyway, just something to consider... BUT, if I am mistaken and you did indeed get a true custom map from MI, we'd love to see a scan of the Dyno graph they provided, the HP/Torque figures, and Todd Egan will no doubt want to archive it at Guzzitech al

-

...holy sh#t, Hare thought your cans were considerably LOUDER than my Leo's?! Good lordee, can you still hear? I thought the darned dyno doors were going to blow off when they were running my bike, and I laughed about how darned loud the thing was at 7k RPM... almost embarrassed Wow, the FBFs must be very loud I can't imagine al

-

....the vaccuum caps unfortunately *aren't* the way to go, well based on my experience anyway Unless you can find a special set that are highly resistant to heat, any of the vaccuum caps you will find at your local auto-parts store will rapidly deteriorate from the heat, and expand, harden, and crack. Soon it will just drop off one day(even with the spring clip on it), and your bike will oddly start to run funny Anyway, the best solution I've found is to remove the brass nipples.. and SAVE them for the occasionally TB balance, and install some short hex bolts with washers. It will take only a few minutes to remove them for TB balancing, and will provide a reliable seal for these ports when not balancing them. This will eliminate one of many intake vaccuum possible points of failure Or of course, a "crossover" or "balance" tube between the nipples will work fine as well. It's just a slightly less elegant solution IMHO al

-

Sorry to hear about that Ray.... odd that the LEO said he would have to cite you just to write the report, not that it really matters I guess As far as the Buell parts. I don't know the part number, but if it's just the lens that's broken, any of the lenses from the late-model Buells will fit. If the whole stalk is broken, I'm not sure. Carl Allison may know. Carl also fitted a Ducati peg after his accident. I'm sure he can give you the part number, and the procedure for making it fit. al

-

Charles, Unless I am mistaken, I don't think the PIAA "extreme" H4 bulbs are HID. They are simply coated halogens to produce a more white or blue light similar in color to an HID. Unless the PIAAs came with a whole kit that included an external ballast, ignitor, and special adapter to fit an HID bulb(which is much longer than an H4) to an H4 base, then it's not an HID. Keep in mind that HID bulbs are much different than a halogen in operation. HIDs are more like an arc-light, and do not have a filament. Typical, but now illegal, H4 conversion kits are usually around $400. And those kits typically do not support high/low beam with one bulb, because with an HID bulb, since there is no filament(s) the high/low funciton cannot be in the bulb itslef. For those few kits that did support a single bulb high/low function like our bikes require, there was a motorized(solenoid) mount for the bulb that physically moved the bulb forward and backwards to change the focal point. But bottom line, the US DOT has been calling the vendors of these kits and threatening them with huge fines, so most have stopped selling these true HID H4 conversion kits. The link I provided a few posts above has a long discussion on this topic. BTW, how much "spare" Wattage do we have on these bikes for lights, vests, etc? I know it's not much... al P.S. You can get kits from places like Micatech that allow one to mount HID solutions externally like halogen driving lights. These kits are sold as both dual and single light solutions, with the dual-light kits running around $400. I believe that for the dual-light kits, the draw is about 85 Watts. More info here: http://www.fjr1300.info/howto/HID.html And here: http://www.micatech.net/Lights.html

-

...or you could put the pump "out in front" like most late '02's have, and as was the standard on the Sport 1100 and Centauro. I think most folks with this setup have avoided the "vapor lock" syndrome that have this arrangement. al

-

If accurate, that's unacceptable, as it's in the middle of the riding season(in North America). There's no reason why the cases can't be made available earlier. I'll call Moto Italiano and check with them and what they've heard as well al

-

Bubbling Engine Paint Service Bulletin

al_roethlisberger replied to al_roethlisberger's topic in Technical Topics

Heck, if you're bothering to do that... just scribe your name in it al -

...oooooohhhhhhh That seems a whole lot more reasonable, and is in-line with what we have seen with modifications of bikes like John's al

-

Yep, my airbox is long gone, and the fuel-pump relocated on top of the spine. I completed "Phase I" .... some months back, which was just relocating the pump and shielding everything. "Phase II" is some replumbing, and dressing it all up a bit better past the prototype/proof-of-concept first stage, and installing a "balance tube" for the tank. Here is the link to that discussion: Relocating Fuel Pump Thread al

-

What's the part# for the spring, so we can just call up a dealer and order one or two "just in case". BTW, can someone post a "how to" and a few photos of where this spring is, and how to replace it? This way if out on the road, it can be done without bringing a trip to a halt al

-

....gosh, do they mean 108hp at the rear wheel!? That seems pretty optimistic. Here is the link to their Moto Guzzi stuff translated to English(well, sortof ): Google-ized It looks like they are doing all the same basic stuff, so 108hp seems pretty stratospheric, unless they are talking at the crank? al