-

Posts

2,744 -

Joined

-

Last visited

-

Days Won

48

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by GuzziMoto

-

I have two different old beam style torque wrenches, the ones with the pointers are typically called beam style torque wrenches because they use the flex of the wrench beam compared to a reference to gauge torque. One is a classic beam style, with the pointer (probably like yours). The other uses an interesting setup, possibly called a split beam torque wrench. It has a two piece beam in something of a scissor arrangement where instead of a pointer it has a sliding scale where it scissors. I don't think it is any better, but it is interesting. While I have two beam style torque wrenches, I rarely use them. Occasionally they are the right torque wrench for the job, but usually a clicker or digital torque wrench is the right torque wrench for the job. Beam style torque wrenches have a couple advantages, including they generally keep their calibration where as a clicker or digital style can loose its calibration over time. But for general work, like installing a wheel, the clicker style or digital torque wrench is far easier to use and get the right torque value. It is hard to apply the required torque using a beam style wrench AND look at the reading while doing so. Far easier to just apply force until it clicks or beeps. I have had to have a second person when using a beam style torque wrench to watch the reading and tell me when I hit the required torque. Much easier to just muscle it until it clicks.

-

My two cents..... Or just remove the valve. The valve only allows venting in one direction. There are legitimate reasons why the tank needs to vent in both directions. From the factory the valve should only allow venting from the fuel tank to the charcoal canisters, pressure can escape. But as fuel is used, air should be allowed back in to the tank. Otherwise you get tank suck, a vacuum developing in the tank as fuel is used. That can result in the tank suck phenomenon of tank suck when you open the tank and the tank re-expands back to normal. But you clearly don't want the one way valve installed in the other direction either as then it would not allow the fumes to vent out of the tank, potentially causing a build up of pressure inside the tank. That could end poorly. An even worse idea. If the valve is installed, you should only be able to blow through it in the direction of from the fuel tank. You should not be able to blow through it towards the fuel tank. If you open the gas tank filler, you should not be able to blow through the end of the vent line to the fuel tank with the one way valve installed. The one way valve is to meet EPA requirements in the USA. The EPA wants the fuel system to be captive, any fumes venting the fuel tank are supposed to be directed to the charcoal canisters, where they are kept until they are feed back into the engines intake tract while the engine is running. In other countries they do not have the one way valve in the tank venting system. It is just some countries like the USA that they do that for. Some people remove the canisters, others remove the one way valve. Some remove both. I would say removing the one way valve is a more important improvement than removing the canisters. I would rather the fuel tank vent goes in both directions. But for racing it was common to run a one way valve that only allowed air to flow into the fuel tank and not allow fuel to escape in the event of the bike being on its side. That was more about keeping fluids off the race track then making the fuel tank work as well as possible. In a perfect world the fuel tank vent would go in both directions.

-

how much engine mileage/life can a well taken care of V11 have?

GuzziMoto replied to fastaussie's topic in Technical Topics

My wife's V11 still has one, has had it for years and many miles. No issues. Some people seem to be able to make a Power Commander work, others can't. But nowadays there are better ways to play with the tuning of a V11. Back then when we bought it there weren't. -

Not sure if they come in the right size, but another option might be a needle zerk fitting. They need a different grease gun nozzle, but are inherently low profile. https://www.amazon.com/Low-Profile-Grease-Zerks-5-Piece/dp/B07B8WM3QZ I don't do Amazon, but this link is primarily so others will understand what I am talking about. Again, I don't know if they come in the required size, but if they do a needle fitting could actually work better in this application.

-

It never ceases to amaze me how often my grease gun ends up empty. And since it has decent heft, it doesn't FEEL empty. So I tend to assume something else is wrong when it turns out I just need a new tube of grease. That said, I have seen a zerk seize so that it won't allow grease in. As others have said, always clean a zerk before trying to pump grease into it. And in some cases you might need to push on the little ball in the middle to get it to pop in. If it won't pop in, it won't allow grease in and may need to be replaced.

-

What Twin AH said. A vacuum bleeder can work, and they are cheap and readily available. But a positive pressure bleeder works way better. A vacuum bleeder tends to suck air into the system. While a positive pressure bleeder will force brake fluid from the reservoir through the system and out the bleeder. Trying to bleed the brakes by pumping the brakes and opening and closing the bleeder is probably the least efficient way. And if you aren't pumping brake fluid in the master cylinder it won't work. That said, if you suddenly lost brake pressure, something went wrong. Have you identified the issue? You may have a leak. That would explain where the pressure in the system went and why you have air bubbles when you try to bleed it. The system is pretty much a closed loop system. The fluid level in the system should only change as a result of pad wear, and that change should be small and gradual. Does your Norge have ABS? Most do, I believe. That adds complexity to the brake system, and in some cases requires telling the ABS system that you are bleeding the brakes so it will hold its valves open. Once you get air in the ABS system it can be difficult to bleed the air out. But for sure a positive pressure bleeder would be a good start. Some are pneumatic, and some you have a pump to pressurize them. The pump up versions are fairly inexpensive. https://www.fcpeuro.com/products/power-brake-bleeder-motive-mot0100 An old trick in a pinch is to remove the brake caliper and force the pads back into the caliper while holding it so the brake line is at the top. That forces fluid (and air) backwards through the system to the master cylinder. You can then work the fluid back and forth using that method, ending up eventually with all the air out of the system.

-

Depending on the battery, 12.75 isn't perfect. For the factory battery, for example, at least 12.8 and change would be full charge. Then there is load, having a full charge voltage wise doesn't mean there is enough amperage behind that voltage. Have you measured voltage at the battery while trying to start? A simple test is to hook up a second source of voltage, either a second battery or a battery charger, and see if the problem goes away. It is usually from the system sensing low voltage during the start attempt, and low voltage can either be from a lack of voltage on the positive side or a bad ground. If the extra 12 volt power stops the issue, it is likely a lack of 12 volt power and the battery is to blame. If the problem is still there with the additional 12 volt power the problem is likely that you have a wiring issue. You should remember that what can happen is if during a start attempt the ECU senses voltage below its threshold it will abort the start attempt. The ECU measures battery voltage through a fairly long and small wire, so there is some voltage drop at the ECU. You can see that by setting the dash to display voltage and comparing that reading to measuring the voltage directly at the battery with a meter. Typically the meter will read higher than the dash. Also to consider is measuring voltage always requires a ground to make an accurate measurement of voltage. A weak or poor ground will typically mean a lower voltage measurement then what it really is. That you both have the same bypass makes me suspect perhaps the bypass is not done right, as with a proper bypass it separates the starters draw from the battery vs the ECUs measurement of battery voltage. That dramatically reduces the voltage drop the ECU sees when you try to start the bike. From the factory the ECU measures battery voltage on the same circuit that supplies the starter as I recall (it has been a while).

-

If you have the 4.5" wide rear wheel I would recommend the 160/60 rear tire. It will fit the narrower wheel better. The wider tire is a bit pinched on that size wheel. That leads to a poor profile shape and a less than optimal contact patch. Later V11's have a 5.5" wide rear wheel and it fits the wider tire fine. Still not my favorite, but it is what it is.

-

Glad to hear it is working out well. Suspension setting are almost always a compromise. It is hard to get one setting that works everywhere. But at least now when you turn the adjuster it makes a difference. That is a major upgrade in my opinion. And I also agree with Pressureangle, getting spring rates right is a fundamental aspect of suspension tuning. and setting your sag should give you an idea of how close your spring rates are. That process has been discussed fairly extensively here, but if anyone wants to dig into that can of worms just let me know.

-

Cheese curds are the beginnings of cheese. They are what you think they are, a result of separating the curds and whey. Then, in most cases, they undergo additional processing to make various kinds of cheese. But you can eat them as they are. They have less flavor typically then the cheeses that would be made from them. But they taste fine as is. In a way they are like concentrated milk. I love meat, but am not much for the various organs and other parts of an animal that aren't "meat". But certainly if I have to eat stuff like that it is better to have more spices involved, rather then less.

-

Scrapple and its relatives are what they sound like, making use of the parts that no one wants (at least that is the way I see it). And while to some they are a delicacy, to me and my wife (who used to have to eat Scrapple as a kid growing up on a farm) they are to be avoided. The wife tells me the way she would eat her Scrapple is to smoother it in Ketchup. Poutine, on the other hand, sounds like something good to eat. I really shouldn't put Poutine in the same boat as Scrapple, Pannhass, and Puddin'. But for some reason I got started down that road when Poutine was mentioned.

-

We don't have Poutine, we have Pannhass, which is like Scrapple. You can also find places around here that serve Puddin', not to be confused with Pudding. Puddin' is also like Scrapple. I actually like Cole Slaw on a BBQ sandwich. It is a common side for BBQ around here, and when eating a sandwich instead of a platter it is common to put it on the sandwich. It is usually optional. But the flavors go well together.

-

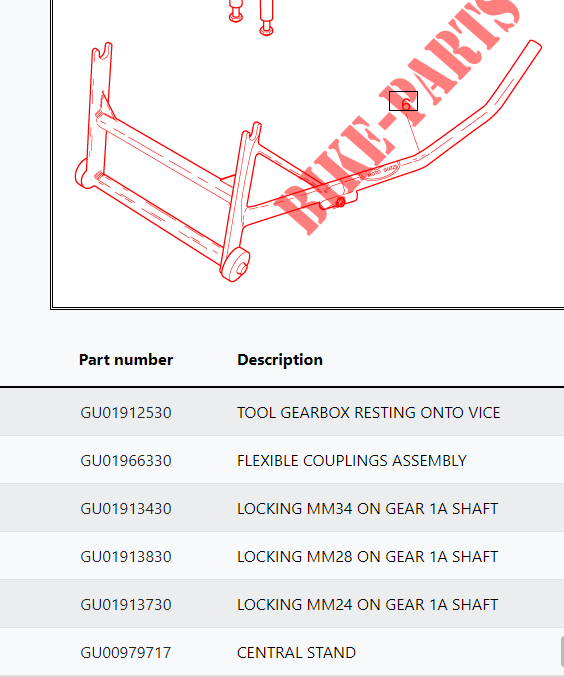

There isn't anything special about a Guzzi as far as stands go. There is that model specific stand that Guzzi sold, I believe they called it a central stand. Item #6 in the parts catalog under Tools Not sure if you can still get that workshop stand. But most any generic stands will work. Some stands require bobbins be added to the rear swing arm, that requires additional work. But a stand that just uses rubber coated wings to pick up the rear swing arm, like this one, will work. https://www.cyclegear.com/accessories/oxford-big-black-bike-rear-stand?sku_id=978434 That one is just a cheap stand, not one I specifically use. The ones I use are old and no longer sold. If I were buying one today I would probably buy a stand from PitBull, as they are a quality brand. But they are twice what a cheapy stand will cost you. On the bright side, not only are they better designed and built than the cheapy stands but they are modular so you can upgrade it later to spools if you add spools to the swing arm. Spools will be more secure.

-

Moto Guzzi V100 Sport Tourer: water cooled, 120 HP (26th of August 2021)

GuzziMoto replied to p6x's topic in Newer models

My two cents, several factors appear to be in play there. For one, the horsepower and torque graphs are using different scales. So a line indicating a given amount of power indicates a different amount of horsepower than the same point wound indicate for torque. Also, it is in different scales for power and torque than horsepower and ft/lbs of torque. Not sure how that transfers. Next, the power measurement is not in rpms but in kilometers per hour. There is rpms across the bottom, but the measuring is actually by rear wheel speed. One more, once you switch to a calculated value, like when they calculate power at the clutch vs their measurement which is at the rear tire, all bets are off. I don't read Italian, but I believe the red line is actual power measured at the rear tire and the other two lines are calculated horsepower and torque at the clutch (we would normally refer to that as power at the crank, but whatever). Either way, the blue and black lines are calculated and not real measurements. That, combined with the different scales for HP and torque mean all bets are off. But that is okay, it is still a good spread of power, and it looks like the new engine is a good one. I hope it doesn't suffer the design flaws of the one it replaces. The 8v motor had good power, but ate its valve train. -

Yeah, righty - tighty more dampening. Lefty - loosey less dampening.

-

What docc said, clockwise / turned in is more dampening. More dampening is slowing down movement of the fork in that direction, so the compression adjuster turned all the way in would be maximum compression dampening and the slowest compression of the fork it can do. The rebound adjuster turned all the way in would be maximum rebound dampening, meaning the rebound of the forks would be as slow as possible. Normally the reference point is the adjuster screwed all the way in as that is a positive stop where the needle hits the seat. When you turn the adjuster out, counter-clockwise, there is often not a positive stop as the needle is simply moving away from the seat. So where it stops is not always identical on one unit to another. It should be, but maybe it isn't. But turned all the way in, all the way clockwise, will always be the same because in that direction it stops when the needle hits the seat. Usually on the street you want as little dampening as you need to control suspension motion. At least that is my take. But if I paid someone who knows more than I do to re-valve the forks I would start with the adjusters where ever they put them. I would turn them all the way in, counting how many clicks out they are, and then put them back to that. From there I would adjust them in or out as required for best results. You could then use that info to have further adjustments made to the valving. If you had to turn the compression adjuster in to get the desired ride quality that would mean the valving maybe needs to be a little firmer, for example. @LaGrasta, just so you know, without blocking off the bypass holes as @guzzlersaid he had done you may find the adjuster has very little impact on compression dampening except in the last inch or so of travel (when the piston has gone by the bypass holes). By blocking off the bypass holes you force more oil to pass through either the valving in the piston or the adjuster. Without blocking off the bypass holes the fork oil is pretty much free to bypass the valving and the adjuster until the piston goes past the bypass holes, which is in about the last inch of suspension travel. The forks can work much better with one or more of those bypass holes blocked off. This seems to be mainly the earlier 40mm forks. I don't think the later 43mm forks have the same issue. But it is hard to say for sure, as has been mentioned you never know which parts are on a given Guzzi.

-

If you are curious, add a temp sensor to the intake inside the airbox. You can get a datalogging temp sensor if you want, or you can just run a temp sensor that displays temp and read it. See how much warmer, if any, is the intake air temp vs the ambient air temp. It should be straight forward. If there is a difference in temps, you will see it. How large the difference is would indicate how big a difference it is making. For sure, warmer intake temps mean less hp. That is what it is. But if the intake air temp of a Guzzi isn't much higher than ambient air temp you aren't going to gain much from reducing it. On the other hand, if your intake air temp is 60 degrees warmer than ambient air temp or more there is clearly something to be gained there. And being temp, it is easy to measure. No point putting in the work to reduce intake temp before measuring to see if intake temp is an issue. Side note, when you run a V8 with a forced induction like a roots style supercharger the supercharger leads to higher manifold / intake temps. At a point, adding more boost by running the blower faster raises manifold temps more than it increases boost, so that the gains from higher boost levels are offset by the losses from higher intake temps.. Running a fuel high in alcohol like E85 cools the intake air, dramatically lowering manifold temps. Measured boost levels may even decrease, because the cooler intake air is denser. But power goes up. A lot. Engine Masters, a tv show on Motor Trend Network, did a show on that where they run a V8 with a roots blower on different fuels, with and without an intercooler. The best combination is the blower on E85 as it cools the intake temps more than the intercooler. It even cools the intake temps below ambient air temp as I recall.

-

Like so many have already said, if you are happy with how it runs now with pods, leave it. It could run slightly better and make a better spread of power if you went back to the stock airbox, but it sounds like doing so would open up its own can of worms as it sounds like it has been tuned to work well enough with the pods. Changing it back would likely mean additional tuning required to get it to run best with the stock airbox. The pods will give up a small amount of performance, but the trade off is a gain in the looks dept (at least in my opinion). If the performance with pods is good enough to you, I would leave it. If you aren't happy with the way it runs, I would put the stock airbox back on and go from there. But just as tuning is required to make it run acceptably with pods, tuning would likely be required to get it to run right with the stock airbox after it has been tuned to run right with pods.

-

Moto Guzzi V100 Sport Tourer: water cooled, 120 HP (26th of August 2021)

GuzziMoto replied to p6x's topic in Newer models

Fascinating. Very much a departure from the past for Guzzi. Truly a clean sheet design. The wet liners remind me of the Aprilia XV engine. -

We missed all this, we were off on a trip out to South Dakota with the Jeep pulling our RV trailer. Hit the Black Hills and the Badlands. While out there we had some good BBQ in the middle of nowhere, Kansas. Pete's BBQ. https://www.google.com/maps/@39.7851445,-98.7850115,3a,75y,345.3h,85.14t/data=!3m6!1e1!3m4!1sp87qiMvCS_rf1w9fgw_Shw!2e0!7i16384!8i8192?hl=en We nearly missed the place as it did not look anywhere near as inviting as it looks in the google street image. It looked closed and maybe abandoned. But the Briskets was really good, and I was glad we ate there. And I always prefer to not add BBQ sauce to what they serve. If they wanted it slathered in BBQ sauce they would have done so. If it needs more sauce than it is served with something is wrong. Adding sauce after cooking seems like the cooking process was lacking. Most of the best BBQ I have had required no additional sauce over what it was cooked with. Also found a great place to eat in the middle of nowhere western Nebraska. Next time out that way we will adjust our route to hit that spot again. Also found a great hot dog joint in Athens, Ohio. O' Bette's Red Hots.

-

Sorry no one else followed up on this last comment. Personally I think insulating the stock airbox is a good idea. My Daytona had an airbox that was under the seat, not wrapping up and forward to the V of the engine. But I think overall the V11 airbox is a better design. But one drawback of the V11 design would be engine heat. Anything that slows the transfer of heat to the airbox should help reduce intake temps. Reducing intake air temps should help make more power. Will it transform a V11 into a fire breathing monster? No. That ain't gonna happen. But more power is good.

-

Looks good enough to me. As I said, I would paint it, so I am not very concerned with the finish, as long as the shape is accurate.

-

I am a firm believer in "If it ain't broke, don't fix it". I would not remove a Power Commander if the bike is running just fine. But if the bike stops running fine, removing it would be pretty high on my list of things to do to resolve the issue. In fact, I will likely be removing the Power Commander on the wife's V11 shortly as it has some issues with the way it runs. I fear the Power Commander has starting acting up. Or not, could be something else. But removing the Power Commander removes a potential source of problems. More than a few people have experienced their Power Commander failing. Electronic devices do that sometimes. Or it could also be the TPS getting itchy and scratchy.

-

I am reluctant to jump into this shitshow, but here is something that some here may not understand. In the world of brakes, brake pistons, and brake pads, it is not about which one moves first. It is about pressure applied to press the pads against the rotors. Even pad wear is about managing the pressure of the pads against the rotor. The pads are never far from the rotors, the distance the pistons travel in a typical application of the brakes is tiny. So whether one moves first or not isn't really what it is about. It is about applying the right pressure across the brake pad(s). That pressure is a product of the ratio between the master cylinder and the piston applying the pressure to that brake pad. Different size slave pistons change that pressure applied for a given amount of pressure at the master cylinder.

-

Is there something wrong with the one you have now?