-

Posts

476 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by cash1000

-

After getting shattered bearing in gearbox replaced I found clutch wouldn’t work. So tried to bleed fluid as line hadn’t been attached to slave cylinder. When pumping clutch leaver I found there was very little fluid coming out. So ok master cylinder has failed so got a kit for it from Aussie. Gave it to a mechanic to do. He fitted kit but still couldn’t pump fluid through. There was no damage to the old kit parts. Clutch was working fine before gearbox problem. I had clutch line disconnected from slave cylinder because I couldn’t remove it from back of gearbox. Any thoughts on what is going on?

-

What's slippery-squirt?

-

Many Thanks Doc. I've just used your info to source a kit from Australia from Gowanloch

-

The saga continues Using syringe method I was able to inject brake fluid from slave to master cylinder. Trying to pump fluid back the other way not so good. Very little fluid being pumped through. Thinking I need to put a rebuild kit into Clutch master cylinder. Teflon tape didn't work so well so under advice from Speed Bleeder guys I've resealed with Permatex high Performance Thread Sealant. It's a 72 hour set time so still waiting. They supply their own sealant but easier for me to get the Permatex stuff

-

Many thanks for the advice. I think I will go with the syringe method with the teflon tape around the nipple to restore the seal. MartyNZ I will contact you about the syringe

-

Getting very frustrating putting V11 back together after gearbox work. I'm having trouble bleeding the clutch line. When I took g/b out I had to disconnect the line because I couldn't get one of the screws holding master cylinder undone. So line is full of air. I've got a speed bleeder fitted to the master cylinder so this should be easy. Nope. I've been pumping on the clutch lever for about 3 hours but I'm getting no pressure. There are air bubbles in the drainage tube and fluid is clear. It was dark when I started. Also there is fluid leaking from the bleeder when I've got it open so is air leaving into line? I got the guy who did the g/b work to replace the 3 screws on the master cylinder. Thought I would take cylinder off and raise it above the handlebars to help purge air. But I can't get screws undone. Tried a heatgun on them thinking he had used a threadlocker no go. He racing at Sound of Thunder meeting this weekend so will leave contacting him untill Monday. Any thoughts?

-

The differcultly was ring gear & clutch plate were in the wrong way around. Looking a picture's on phone didn't show ridge on plate and indent on ring gear. Printed photos out and bingo the problem was obvious. Gearbox now fits onto clutch- easy. Now in process of putting bike back together.

-

Good thinking on both ideas. I will give them a go

-

OK I'm going to remove gearbox & clutch and start again. Probably next weekend

-

Its only got a single clutch plate so that plate only needs to be centered. A twin plate would need 2 plates lined up & centered. I took note of all line up marks on clutch & flywheel before I pulled apart plus reference to Greg Benders video so that part should be good . I will try with trans in gear. I suppose I'm trying to hit 2 moving target's at the same time. How do you know when it aligns?

-

Not a different g/b Vince repaired original one. G/b proving stubborn to refitt. I'm obviously not getting splines lined up. I can get cases 2mm apart. I can move alternator nut. If I tighten nuts to join cases just a couple of turn's then I can't move alternator nut. If I ensure gap in between cases is the same all round then g/b should be lined up with clutch splines. I should then wiggle alternator nut untill splines join. In theory.

-

I'm reinstalling original flywheel & clutch. Plan is add a V85TT to fleet to do any long distance riding on so mileage on V11 will be less. I've used a vinier caliper to centre clutch plate. Have another go at gearbox tomorrow

-

Thank's Doc. Makes total sense when you think about it. Out come's gearbox again

-

I'm having trouble refitting the gearbox. I can't get the gap between the gearbox & engine cases to close up. Is it that the splines on the gearbox are not meeting up with those on the clutch plate? The manual talks of a clutch alignment tool. Do I need this?

-

From the album: Cash1000

-

Head lift stand compatible with v11 Sport or Lemans

cash1000 replied to al_roethlisberger's topic in Technical Topics

I use a DRC stand. The 15mm pin fits my RM fine DRC B2510 Road Front Stemup Stand – Cycletreads It's the opposite here in New Zealand 30+ C. -

Yup. When I removed it to drain oil it had metal fragments attached to it. Not a nice sight

-

Pick up completed gearbox yesterday. Great service from Vince. 2 weeks earlier than I expected and cheaper Got some painting to do before I re fit. Paint flaking off from top & bottom of gearbox plus some touch ups to swingarm etc

-

Many thanks for posting correct page

-

Yup my bad wrong page

-

Working on what needs to be done to install flywheel & clutch Found this on Greg Benders website for an 850T. The clutch is different for the RM but is the instructions correct for the flywheel for the RM? Install the flywheel and clutch - Roy Smith's Moto Guzzi 850 T3 engine rebuild - Project motorcycles - Topics - Gregory Bender (thisoldtractor.com)

-

From the album: Cash1000

-

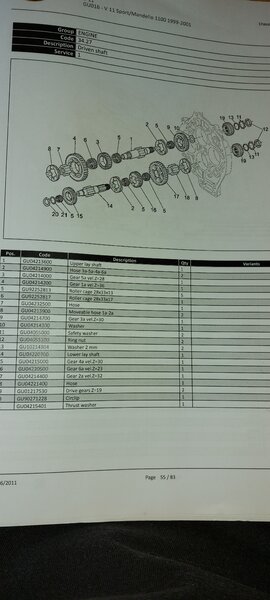

Just heard back from Vince. The failed bearing was rear one on upper lay shaft. Can any one point out in parts diagram which is the bearing that failed?