-

Posts

5,000 -

Joined

-

Last visited

-

Days Won

257

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Lucky Phil

-

I've been there Chuck, should have dealt with something when I was in San Francisco when I was over there but didnt even think of it till I got home. I happened to buy 2 of these granite plates at the same auction and gave one to a good friend with an engineering business. His was nicer looking than mine with a green hue to it and a return around the perimeters. Apart from the obvious dimensional stability compared to steel he pointed out that if you do happen to damage one it will chip and not deform locally so although if damaged its still dead flat. Its a bit like owning a lathe, you dont use it all the time but when you need it you really need it and it nice to have there. The lapping plate is great to have, many of the crankcase surfaces, heads and barrels get a session on that to clean up the finish and confirm flatness. I even managed to use it on the crankcase sump surface, the plate was just big enough for that as well. I love the independence having equipment gives you and in reality I dont have much really. I'd have a lot more if I could afford it, justifiable or not:) Ciao

-

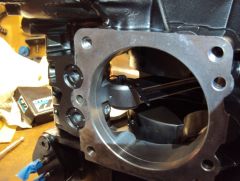

Progressing slowly. Cylinder and pistons fitted along with sundry cam drive bearings and spacers. New tensioner rollers and bearings fitted and seals replaced although it looks like I need to turn the tensioner rollers around for some reason looking at the shop manual images. No idea why it matters as they are dimensionally the same whichever way around they are fitted. All the ring gaps were measured and fine without adjusting. Piston to cylinder clearances were both 0.04mm and cylinder barrel faces given a light lapping on the lapping plate. I'll probably move onto the sump next and leave the heads until last just for the convenience of fitment and having the engine on the bench. A proper engine stand is what I really need. The plan is to have it all together with the exception of the timing cover and oil pump drive so I can spin the pump with a drill and prime the oil system then fit the pump gear and front cover. I expect it to be a bit messy this approach. Ciao Here's my granite surface plate and my lapping plate. I bought these about 20 years at a closing down auction for an engineering shop. Best money I ever spent. If you see some under the same situation snap them up. they come in handy for many things. Way to expensive to buy retail new, well back then they were.

-

Funny story. Couple of years ago they set the drug bus up on the hill coming out of Queanbeyan and were pulling over everyone. I was on the Griso with Mistral Hi-Pipe with dB killer in and the bloke in front was on an R6/R1 type thing. He had not only an open pipe but had tried that thing that 'tards do of mounting his numberplate inboard of the wheel in front of the shock. Oh my! That was fun seeing him get the third degree as they defected him on the spot, made him unscrew his plate, drug and piss tested him and then told him to @#!#$# off and walk home! They drug tested me but probably only because when they asked me if I'd ever taken narcotics I said "Shit yeah!" But then explained the last time was probably close to forty years ago and it was really shitty sulphate and I was ripped off! Not huge on the sense of humour that one! No issues with the noise though. Even though my Griso sounds like cheesgraters fornicating in an iron tank! Good one Pete. No sense of humor coppers. All about 18 years old these days and not enough mileage on them yet. I thought it was pretty typical when they were busted recently for fiddling the RBT tests to make their stats look good,sigh. Of course there are no booking quotas either. Ciao

-

When Pete says something, it pays to listen. He has worked on Moto Guzzis before. Looking at your first post, it seems like pic 1 oscilloscope trace shows a lower sensor voltage and lower speed than pic 2. The SENS813 is an inductive pickup, which would put out lower voltage pulses if the gap to the phonic wheel was large. I think you could try reducing the SEN813 sensor gap to the minimum, and temporarily leave the o-ring seal out, just to check. As I see it, the sequence of events in the ECU are: 1. ECU Power on, self test, sensor check, and pump prime. 2. The ECU then waits until SEN813 pulses reach a "run" threshold. 3. The ECU will then turn on coils and injectors as instructed by the BIN file program. If the SEN813 sensor is faulty, or if the gap is too large, the ECU will not power the coils and injectors. As Chuck mentioned, electrical connectors can cause problems, and it is a good idea to remove and clean the connector to the ECU. What does your instrument panel RPM display show during cranking when it is sparking and not sparking? Be aware too that your manual says "If in the wrong position, the bank angle sensor may lead to sudden engine stalling". You mentioned this at the start, but you could try disconnecting it. thanks marty. Today I heard from the owner, car hit the parked MGS! so reassembled the left engine head by ex-repair shop before. and that the engine did not start after that. If so, it would have been reassembled the timing belt. Fortunately,the valve and the pistons are not contact. there is strong doubt in timing belt assemble. i want to reassemble timing belt, but the contents of the manual are not sufficient. if there incorrect belt assemble, Could there be a difficult section of the starter motor running? (when Left piston do uprise, Right piston cause a pull?) I agree If starter motor running slow, it could interfere with the operation of Sen8I3 as pete said. As I said, troubleshooting step 1, what was the very last thing done on the bike before the issue? Ciao

-

I'm hearing you Pete. I despair these days watching morons riding around on old shitters from the 70's and 80's stripped back with no guards,indicators or mufflers, just straight pipes and the type of tires shown in the OP image. Back then (1980's) I had to keep a sharp eye out for the cops and those pricks from the EPA that pulled you over for a random noise check all because I rode a bevel drive Ducati fitted with Conti's. Now apparently anything go's including Harleys without any form of muffler. I swear 90% of Harleys here dont have mufflers but you never see them on the side of the road getting a defect notice. Rant over. Ciao

-

Which fuel do you use, What ECU map and do you have any pinging?

Lucky Phil replied to antmanbee's topic in 24/7 V11

Mine stopped the cough as soon as I went to gear driven cams. Ciao -

All I can say is I'd decline any ride on a bike with a front tyre like that. Ciao

-

I've just got this feeling that something basic but unusual is being missed and we've jumped to the complex stuff to soon. Try the bump just for the sake of elimination. Ciao

-

I didnt actually see the video in the original post so I checked it out. How about you put it all together and try bump starting it. Its a pain bumping a big Vtwin but i'd be interested to see what happens with the starter out of the equation. Even to see if it tries to fire up. IE you get an ignition event. I suspect the starter itself or the starter relay pulling the voltage down even with the other battery. Ciao

-

I could have sent you one of Chucks springs. Anyone out there that has a broken spring let me know I can send you one as I have spares generously donated from from scudd. Ciao

-

Excellent, do they by chance also have a bar that serves up a decent red as well Pete? Ciao

-

Here's a basic question......what was the very last thing you did to the bike before it wouldnt start? You would be surprised at the answers you get at times......" nothing really, gave it a wash thats all!!! Water, electrical connections? you know what I mean. Think about the very last thing. Ciao

-

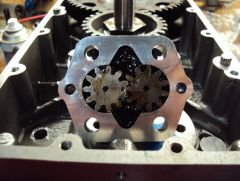

So some progress today. I managed to fit the rods and jackshaft, jackshaft gears and oil pump. My methodology with the rods was to fit the clutch assy temporarily so I could lock the crank with the pin in the position nearest the open sump and then fit the rods and cable tie the small ends together to stop them rotating about as I torqued the big and bolts. I had already torqued the bolts to 50ft/lbs and measured the stretch at between 0.005" and 0.007" so I knew what to set the wrench to to achieve the desired stretch. All worked out fine and I managed to get the mike in there and confirmed the stretch figures anyway. I have a Summit racing big end bolt stretch tool so you can pull the bolts up without the torque wrench and watch the stretch as you pull them up but it wont fit in the Guzzi cases so I did it the painful way. One interesting thing was that I noted when fitting the jackshaft ignition trigger phonic wheel that it comes quite close to the front main bearing flange. I pulled out the old front main and sure enough it had been shaving material off it. This is what happens when you run the old style jackshaft front bronze retainer without the oil reliefs. They wear quit badly then the shaft can move rearwards and the phonic wheel starts to contact the main bearing flange. Mine has around 0.9mm clearance and the new jackshaft retainer so I'm expecting it not to wear as badly as the original which had around 1.2mm of wear. I've seen people refit these with this amount of wear funnily enough. Here's what the phonic wheel does to the front main flange when the cam/jackshaft flange wears. 1200, oclock shaving of the flange. Here is the point of interference. Not a massive issue but it will start making metal when the jackshaft/camshaft front flange starts to wear. Its aluminium though so its not so bad. If you're in the front timing area and your engine has some yards on it it would be wise to replace the cam front flange with the newer type. Packed the pump. Here's what a badly worn front cam retainer looks like. Ignore my lock wiring hole drilling practice. Note the recessed thrust face. Its not supposed to be like this although I've seen many people refit these not realizing they are badly worn. You can get the mike in there but for some bolts you need to read it with a mirror.