-

Posts

5,220 -

Joined

-

Last visited

-

Days Won

268

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Lucky Phil

-

-

From the album: V10 Engine

-

If you need to use a hose clamp around the filter then there's something wrong with the filter the filter threaded adapter or your installation technique. I dont feel the need for a hose clamp around any of the other 6 vehicles I own apart from the Guzzi why should it need one? Ciao

-

I just do it through the round port access cover, and yes it can be tricky to get the thread started. Ciao

-

Just some feedback on the timing gears. Rode into the city yesterday for lunch with my wife which entailed about 60klms of freeway riding at 100 klm/h in 26 degC heat at around 2900-30000 rpm indicated. It still coughs and stumbles at around 3000 rpm occasionally. So the gears aren't the answer to that it seems. looks like mapping. Ciao

-

Well its been a busy time with other stuff unfortunately such as my lathe breaking down and requiring motor disassembly and centrifugal switch work and a new start capacitor. Its still a work in progress as I await the new capacitor.The rocker shims arrived and a new learning in the form of a rocker arm with end faces that aren't machined perpendicular with the pivot axis so getting the end float right is a matter of using the smallest gap. Its too awkward to hold in the lathe to machine the faces and I dont think it will be an issue so I'll leave it as is. The new Oil pressure spring also arrived so it was onto testing the crack pressure with that fitted. It wasnt a successful outcome I'm afraid. The new spring is around 2 mm longer than the old spring but its still not enough to get me the required 70psi crack pressure. Even if I shim the spring to a silly amount its still not enough. So after time spent lapping the valve and getting the sealing faces as perfect as they are ever going to be I'm here to say that there is no way 70 psi of oil pressure is possible with this spring. I figure that the valve will need a minimum of 6mm of stroke. The spring with 18mm of preload will accomplish that but all I can achieve is 55psi crack pressure. The new std spring is in the 10.8lb of seat pressure at 18 mm of preload. So either I accept 55 psi or look for a heavier spring. So here's one for the more knowledgeable than I. I have tested the new springs at 0.6lbs/mm ( I know mixed parameters) so at 18mm of preload I'll have a seat pressure of 10.8 lbs. My calculation for spring pressure required is as follows. Assuming I need 70psi, for crack pressure and assuming I had 1 sq inch of piston/valve area then Id need a spring that provides 70lbs of seat force. What I actually have is a valve that presents 95.4 sq/mm to the oil supply which is 14.8% the area of 1 sq/in (which is 645.16 sq/mm) so 14.8% of 70 pounds is 10.36 pounds of seat pressure required. The new spring is giving 10.8lbs of seat pressure and I'm nowhere near the 70psi crack pressure. Any Ideas? Is my spring rationale calculation lacking? Spring tester. New spring Old spring New spring Old spring Ciao

-

Thanks Kevin, I'll go with .2. I managed to juggle shims around as they are all a little different and got 2 rockers in tolerance but 2 are nowhere near. It seems the inconsistency is in the rocker length not the carrier Ciao

-

Do you mean that because technically the V11 pictured here is below sea level, its like a boat anchor docc Ciao

-

Thanks for your input Pete, we are all in furious agreement then I've ordered some custom shims which I should have next week. Ciao

-

Thanks Chuck, I tend to agree, it certainly feels more correct and wouldn't be as noisy either I don't think. I just gave Brad Black a call and he was of the same mind so that's 3 to zip so I'll go with that. Brad also gave me the number of a local business that makes shims to order which is also a big help. I'll submit and order for a quote from them and see what the damage is. None of my Ducati gearbox shims are quite right unfortunately, nor are my stash of general shims. Ciao

-

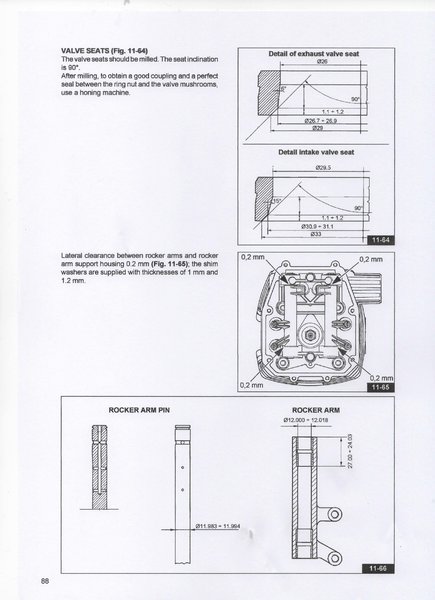

A question for those that have been inside the Daytona engine. Rocker arm side clearances. The original Daytona manual advises 0.2mm clearance with no image support which feels about right. However checking the later Centauro/Daytona manual the text is the same but the image seems to show 0.2mm clearance at each end giving a total clearance of 0.4mm. Now the shims come in 1.0 and 1.2mm thicknesses and achieving the 0.2mm overall total is close to impossible without making some shims myself. Anyone ever experienced the end float on these? I didnt note the clearances when I pulled the engine down all those years ago and 0.2 seems to "feel"' good while 0.4 "feels"a bit loose. Not sure if the manual is saying you measure 0.2 at each end or you can measure either end. Why wouldnt they just give you a total. Ciao

-

From the album: V10 Engine

-

They got it right in the end though didn't they Pete? I like the Griso roller lifters better than the V10 flat tappet design. You could convert the V10 engine to roller lifters, it wouldn't be outrageously difficult. I looked at it with that old Griso lifter you sent me and then the images you did for the roller conversion. A couple of tricky bits but nothing that someone like Chuck with his machinery and engineering talent couldn't do. One thing though, none of them look better than the V10 high cam engine. Its a pretty sexy looking thing. Ciao

-

Component rich:) Ciao

-

L/H head ready to fit. One for the detail people and if it ever arises for those getting inside a 4 valver. Different spring retainers and although not really apparent in the image fractionally different keepers. The black retainers were from a pair of heads I bought from Paul Minnaert and are slightly different in dimension to the silver ones from my original engine. The keepers are also a slightly blacker tone and have slightly different dimensions. It may be just different time and suppliers but I kept the black keepers with the black retainers and likewise. Using the black ones gave less spring pre-load and would have required shimming the valve springs. The black keepers with the silver retainers also didnt produce a solid feel when installed without the springs as there was a slight rocking. Fine with like ones.I used the silver ones in the end. New rockers pins and adjusters ready to fit after the head go on. Ciao