-

Posts

5,215 -

Joined

-

Last visited

-

Days Won

268

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Lucky Phil

-

So I weighed the V10 Sport today. The bike has a wheel/tyre/axle combo that's 9KG lighter than stock and a single plate aluminium clutch and flywheel and about 80% Titanium fasteners for reference. It also has the chin spoiler, bikini fairing and a Wilbers full spec shock with remote hydraulic preload adjuster. Total weight......231Kg with all fluids and no fuel. Front 114Kg- Rear 122Kg minus 5KG for fuel. The centre of the wheelbase is in line with the gearbox to engine interface. I've never liked those scales. Phil

-

Not quite right. The ratio area of the master to the slave cylinder determines the force that can be applied (and the lever ratio as well but we'll leave that) and the "travel" of the master and therefore the volume of fluid displaced determines the travel of the slave. Phil

-

Thats about 20% what the rest of the world want for them. I think AF1's pricing might be a little suspect. Phil

-

ANSWERED Acceleration Enrichment Map-2004 Rosso Corsa

Lucky Phil replied to Rob NZ's topic in Technical Topics

My point is when you mark the throttle housing to give you a rough indication of the throttle position don't mark the fully closed position as zero or you'll be even further out in your already rough and ready attempt to indicate throttle opening. Yes a multimeter is required because GD isn't accurate enough. Phil -

From the sealing face on the sensor flange to the centre of the sensor is 135mm plus the 2 mm thick sealing washer so 137mm total. I made the sealing washers myself from HDPE and will make any plastic components I need from the same if the final design needs a plastic component. Phil

-

ANSWERED Acceleration Enrichment Map-2004 Rosso Corsa

Lucky Phil replied to Rob NZ's topic in Technical Topics

Just see what Guzzidiag indicates as closed throttle degrees. The fuel map has throttle position break points below the actual throttle blade degrees at the set idle position. So your bike will probably have a throttle angle of 4 degrees or so at idle. Dont assume that the lower throttle break points like 2, 2.4 2.9 etc are a factor when you are estimating your throttle percentage from fully closed when riding. Your base line closed angle is probably around 4 degrees not zero. Just sayin. -

That is misguided. Phil

-

ANSWERED Acceleration Enrichment Map-2004 Rosso Corsa

Lucky Phil replied to Rob NZ's topic in Technical Topics

Don't forget to calibrate your throttle closed position to the angle guzzidiag reads out as a closed position. It's not perfectly accurate but it's not zero either remember. Zero out the Co setting as well. Phil -

Yea. Guess what look you get when you tell a club racer that before he starts drilling shift levers and foot peg brackets to save weight he may want to consider shedding the extra 20kg he's carrying. Phil

-

It's a cumulative thing at the end of the day. On my bike the wheels and axles have saved 9 kg's and the clipons a bit as well as the mufflers and cross over and various Titanium bolts (In fact just about 90% the bolts on the bike) A 4-5 kg weight saving on the battery would be quite a nice reduction in one hit added to the other stuff when it comes time to buy a new battery. A good saving in dollars/KG esp if you need a battery anyway. Free weight reduction. I still use the std battery but next time I'll go to the Lithium I think. I must weigh my bike and see what the total is. Phil

-

The plastic housing isn't optimal as it eventually becomes impossible to seal. As soon as you remove it and reinstall it won't reseal in some cases. So aluminium housing is what I'm planning. looking at the original design gives a clue to the fact it's not a no brainer situation. Many of the thermistors which are easy to source have an external earth wire soldered onto the case which won't work on the V11 sensor because the external earth wire wont go through the tank fitting dia wise. So that needs to be removed and the earth done via the fitting at the top as in the std version which I have disassembled. It's one of those things where when you pull it apart and study it the details become apparent and the complexities involved in remanufacturing obvious. So the original plastic housing has an aluminium fitting pressed into it and the thermistor is crimped into that. The aluminium housing has a drain hole and an earth lead crimped into it and the insulated live wire through the centre. The plastic housing is hollow down to the drain hole in the image and the rest is filled with an epoxy resin encapsulating the wiring where it exits the tank fitting. The dia must be kept std as thats all that will fit through the tank fitting opening. Basically it's a case of making the plastic fitting in aluminium and the thermistor is either crimped in place or maybe a small pair of set screws below flush. Fuel proof epoxy, wiring and heat shrink. Phil Body drain hole Thermistor in place but with with crimp machined off Back side of aluminium fitting with earth wire crimped onto fitting, drain hole in fitting and supply wire through the fitting in the middle. Top and bottom of thermistor canister has drain holes.

-

From the album: lucky phils V11

-

From the album: lucky phils V11

-

From the album: lucky phils V11

-

ANSWERED Acceleration Enrichment Map-2004 Rosso Corsa

Lucky Phil replied to Rob NZ's topic in Technical Topics

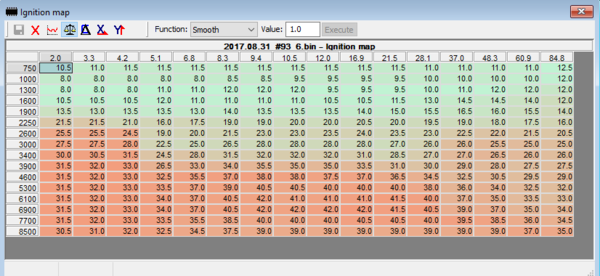

This is true. 15M running a Daytona engine with my own map. Phil -

ANSWERED Acceleration Enrichment Map-2004 Rosso Corsa

Lucky Phil replied to Rob NZ's topic in Technical Topics

I suggest you leave it alone. So all the V11 maps I've looked at, Meinolfs custom map, the std v11 from 2000, the Rosso Mandello, the factory map for the Titanium exhaust all use the exact same acceleration map numbers. I've never touched my accel map which is the same as the std V11 2000 map and all the others running a Daytona engine. The std 16M Daytona and Centauro maps dont even have an accel map. Phil -

I bought one of these a while back and used it to mount the new tyres to the PVM wheels on my V10 Sport. I've looked at various tyre changers over the years such as the No Mar etc and was always unimpressed by the size and the fact you still need to lever on the edge of the rim and unless they are bolted down you seem to chase the unit itself around the shop floor. The Rabaconda is brilliant to use. The force of stretching the tyre is directed into the ground so it's very stable and the ratchet system is easy on the body and the "ducks head design which is basically the same as a powered machine keeps the rim safe. For people that do miles and the cost of tyre fitting these days it's a good investment. I rate it.

-

Yes easy to miss a cable connection on the v11. Phil

-

Ignition switch. Phil

-

ANSWERED Acceleration Enrichment Map-2004 Rosso Corsa

Lucky Phil replied to Rob NZ's topic in Technical Topics

A few things. Lambda sensors were fitted to, well most injected vehicles for a few purposes and in V11 terms none of them were to make for a particularly better riding experience. They were installed for emission and to some extent fuel economy related reasons and for CAT considerations. So at "steady state throttle settings" and a certain rpm band the O2 sensor trimmed the fuel to stio correct or whatever it's target happened to be. Generally this area was what we would call the cruise area. Steady state rpm and throttle angle. Freeway cruising in the main. The other area Lambda sensors are advantageous is for Long and short term fuel trim applications to trim the fuel system as the name suggests. So the ecu can compensate for engine wear and various other mechanical degradation and trim the main fuel maps accordingly, LTFT. It can also adjust short term fuel trim STFT to compensate for things like dirty air filters etc and also general driving habits. The STFT can be " nulled" by pulling the ecu fuse or disconnecting the battery as it's a volatile memory. Commuting will in a lot of cases influence the STFT and affect the riding/driving experience in a slightly negative way. Pulling the ECU fuse will reset this and the STFT will revert to the original zero setting and improve the engine running slightly until the trim shifts it again. It's an arguable thing but lots of people do it. Wide band sensors work better than the cheap narrow band sensors that's been a fact for many years. So basically the LAMBDA system in the V11 context and most earlier generation motorcycle systems were for emission related reasons combined with fuel economy not for a better riding/driving experience and in car applications for the same reason plus the afore mentioned LTFT and STFT ability because cars do a lot more miles than motorcycles generally with a lot less attentions to keeping them tuned and serviced and running well. If you have a V11 with the later 15RC ecu and Lambda fitted then simply disconnecting the Lambda and mapping the ecu will give you a nice result without the Lambda system complexity. Maybe the fuel economy will be slightly worse, not sure but then again if it's nicely mapped it will be slightly better than stock probably. Phil -

Gigi has a history of liking to give riders he believes were treated unfairly, overlooked or considered has-beens a chance or second chance' Iannones signing is no surprise to me. Phil

-

What's my first rule about troubleshooting before you do anything else. Ask yourself the question "what was the last thing I did before the issue arose"? Wash the bike? fuel the bike? Have the seat off? replace the battery? You get the idea. Phil

-

MotoGP is fast disappearing up it's own arse like F1 has. Less and less relevant to the buying public and less and less about the riding and more and more about the tech and the "show". That's why WSB is so much better than Motogp these days. Aero and ride height devices have ruined MotoGP as smarter people close to racing predicted it would. It hasn't completely wrecked it but it's on the pathway. Now we have a situation where every rider is riding at 100% all the time and the difference in winning or not winning is down to the bike and what setting or tyre you chose or whether or not you got into a group and your front tyre overheated or you had a poor qualifying or someone got a tow from you in qualifying and although you were actually faster than them on a hot lap you towed them around and they gained 2 tenths on you thanks to your tow and you ended up two rows back on the grid to them because of it! When a rider can no longer "make the difference" in a race by shear determination and sticking his neck out to overcome a slight setting issue or tyre choice then it's going in the wrong direction. Speaking of qualifying we need to return to the one lap shootout system. Riders getting a tow off faster riders or riders getting shafted on their last "hot lap" because another rider has crashed and brought out the yellows is a joke. Now qualifying on the front two rows of the grid is mandatory for a decent race result because of the Aero and suspension issues you need to have a truer picture of who has the raw speed and award those riders accordingly. No point having a rider who should actually be on the 4th or 5th row on raw pace actually being on the front or second row because he used the faster rider for a "tow". The flag drops and he just gets in the way of the guy who's actually got the pace. Aero is the reason front tyres overheat and the reason overtaking is more difficult and it's totally a blind alley for road bikes. Same as squatting devices and front suspension launch devices. Because Dorna dumbed down the electronics and banned electronic on the fly suspension control which are a direct benefit and eminently transferrable to road bikes the MotoGP engineers turned their attention to Aero as another measure to claw back some of the loss. Problem is none of the Aero or manual squatting devices are useable on a road bike so the technical investment is a dead end to the manufacturers and the consumer. Don't confuse the aero on superbikes as useful they are almost entirely a decoration and a joke to the aesthetics of a road sports bike. Have you seen the ridiculous front wing on a BMW and they still can't win races with them. At the core of motorcycle racing is the rider NOT the tech. The further down the none relevant for the consumer tech road the less it becomes about the rider. It's what has always separated motorcycle racing from the joke F1 has become. If you are going to move ahead with the tech which is inevitable then at least direct it down the path that benefits and is relevant to the consumer. Speedway is one form of Motorcycle racing where the tech has deliberately been capped for 40 years or more to make it a "sport" about the racers NOT the motorcycle. Seems to have worked well. Not supporting those measures entirely but the current direction by Dorna is all about the "show" and not the sport. I see now the riders are forming a union so they have some say in the direction of MotoGP racing. Might be a good thing I think. Phil

-

From the album: lucky phils V11