-

Posts

5,230 -

Joined

-

Last visited

-

Days Won

268

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Lucky Phil

-

I didn't want to get into "pumping losses" and drain back speeds etc. Honda RC30's when they first started racing them were destroying big end bearings because the oil pumped into the heads couldn't drain back to the sump fast enough so the oil level dropped enough to cause cavitation. Robert Dunlops bike in the pits at the WSB round back in 88 or so had extra external drain back lines from the head to the Crankcase but I think the real fix was to reduce the qty pumped there to start with. Honda had excess oil going to the heads so they fitted restrictors in the end I think. Ciao

-

Probably because it's a more indicative indication of the level when running as opposed to the level when every last bit of oil possible has drained back to the sump which is not really the case in operation. Could also be because for long journeys and top offs the engine is more likely to be warm when oil is added, who really knows they are Italian and I doubt there's really that much thought or science involved along with the typical translation vagaries. It's of little consequence whichever way you do it really. Might reflect a few hundred ML of difference. Not sure the differential expansion between mineral and synthetic has anything to do with it as I doubt there's any real difference between the two anyway. If anything I would have thought it would be the other way around with the Mineral oil relying on Viscosity Index Improvers that expand as the oil temp rises unlike Synthetic oil which doesn't need them. Ciao

-

Sounds like my brush cutter to me docc. Ciao

-

Sorry but you and I are on different planets with regards to what sounds good. That Video is bordering on obscene on several levels. Ciao

-

No. Ciao

-

True, generally through the right handlebar at around 3800 rpm. Ciao

-

I've owned both the RC30 and the 851 with the reverse cone megaphones. They were way to loud for the road though and I ended up with a full alloy can SP2 system on it. The RC30 sounded nice at WOT mostly due to intake noise. If you've ever heard a WSB RC30 running in the pits without the backlash gears fitted to the cam drive gears which is how they were run back in the late 80's you'd be shocked at the mechanical racket once they got warmed up. Ciao

-

From the album: lucky phils V11

-

From the album: lucky phils V11

-

No match for one of these esp with hi comp pistons and race cams. The Panigale V2 WSB's sounded the best of all the twins at race speeds At PI they had a sharp rasp to them at WOT and full revs down the chute and downright dangerous but the best bit was the initial crack of the throttle out of the slower corners like Southern loop. Even from 100 metres away as the rider stood it up on the fat part of the tyre and went WOT for the first second or so you could hear the induction roar from the twin 70mm throttle bodies easily over the exhaust. A truly evocative sound. Big twin sound is as much about the throttle body noise as the exhaust. Older versions like my 1198 had a much mellower sound on the track but sounded muscular and serious compared to the screaming 4 cylinder WSB bikes. They just sounded fraught. These sounded OK. Ciao

-

One way up it drags on the cover. Ciao

-

So you have aligned the dots on the gear wheels and then shifted the mechanism into neutral to fit? It's hard to see on your low res image but it looks to be a tooth out to me. Ciao

-

With a LiPo battery in cold climes you need to turn the headlight on for a minute or two before you try and crank the big twin to warm the battery up. This is the accepted process. Ciao

-

This is why I never run anything other than clear scratch pads. Even if you can't use an identically shaped replacement it doesn't matter as there will be no fade line. I guess you could always source some material and make the shape to suit the fade lines. Ciao

-

How much fuel in the tank? Full? sounds like the breather hose is restricted/crimped and return fuel is pressurising the tank. Ciao

-

Hard to say about the pinging but if your shifting into 6th gear at anything below 100kph/60mph then you're looking for trouble in that department. Ciao

-

Thats why you buy adjustable ones. Ciao

-

You will probably only be able to get 1st and neutral without turning the back wheel to line up the dogs on the gears and drive sleeves. Find the neutral position on the selector assy and move all the drive sleeves in the gearbox to the mid position between the gears and dry fit the cover and make sure it seats. Then carefully remove and apply sealant and install. make sure the cover seats by hand, don't use the screws to "pull it into the seated position" Read this. Ciao

-

It's not only the tread that wears and degrades but the carcase as well. New tyres feel and steer nicely because the carcase isn't fatigued and degraded through millions of flex cycles and is it's true shape and stiffness. Ciao

-

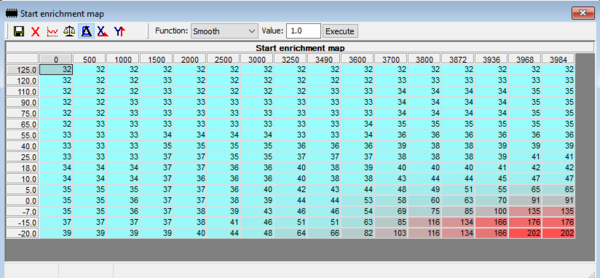

All true. A 10 min warmup!! thats not good for fuel economy. Remember as I've mentioned before and most now know stopping and starting the engine especially from cold chews fuel in a major way due to the cold enrichment mapping. So 10 cold starts commuting to work and back will see the fuel economy dip alarmingly on that alone never mind the suburban traffic. Also every time you shut it down and start it hot it also goes onto the rich 3986 revolutions start mapping. So a 10 cold start week commuting with a few hot starts thrown in there for buying milk or whatever and the economy is going to suffer big time. Ciao

-

From the album: lucky phils V11

-

Bike runs great...then misfires...then, minutes later...

Lucky Phil replied to VtwinStorm's topic in Technical Topics

Well docc it's 3984 to be precise. Ciao -

Bike runs great...then misfires...then, minutes later...

Lucky Phil replied to VtwinStorm's topic in Technical Topics

4000 revolutions docc. Ciao -

Transmission Level Indicator Window Removal

Lucky Phil replied to PDBoulder's topic in Technical Topics

Just throw the thing in a small jewellers ultrasonic bath to clean it. Ciao -

Bike runs great...then misfires...then, minutes later...

Lucky Phil replied to VtwinStorm's topic in Technical Topics

So the issue was the electric fuel tap connector wasn't connected correctly? Ciao

.png.d2f786a0119378431262c85878da2b15.png)

.png.3c686043b6059b579b1f1ddf8ce44e05.png)