-

Posts

5,003 -

Joined

-

Last visited

-

Days Won

257

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Lucky Phil

-

I just wired the headlight with its own dedicated supply and a couple of mini relays to eliminate the voltage drop in the light circuit so the reg doesn't get fooled. Ciao

-

The alternator rotor is on a keyway so it will be in the same place. Ciao

-

Ok Pete so its now a solid pin apart from some maybe 5-6 mm drillings from the mains and the same size through the pin intersecting them. A largely solid pin then? 7.1 KG seems pretty light as well. Ciao

-

Nice Pete, not too impressed with the sludge trap omission. There's always quite a bit of rubbish in there and its nice to know you've got it cleaned out properly if you have the engine apart. Spose there's quite a few around with DLC coating living in the pin. Ciao

-

Yep. The way to go is use the dead stop method and if the flywheel marks are wrong the make your own. Only need to do it once. Ciao

-

You need to number these things Chuck, after all they are a "limited edition" May be worth a fortune in a hundred years:) Ciao

-

Here's how it works docc if it is indeed the case here. An overfull reservoir leaves no room for fluid expansion so you can sometimes to an extent get away with it until it gets warm/hot. So if the reservoir is overfilled when you pull the lever it will as usual squirt a little fluid back into the reservoir until the secondary seal is exposed to the fluid and the fluid connection hole is covered. The problem is now the reservoir is totally full and when the clutch springs/spring tries to back drive the master the master cant push the fluid back into the reservoir because there is no available room for the displaced fluid to return. Your hand pulling the clutch lever generates more force than the pressure plate springs trying to return the system to the null position so even with the system totally full the hand force can create enough expansion in the reservoir (up to a point) that allows disengagement but then there's not enough force from the pressure plate springs to do the opposite. If you were aware of what was about to occur you would probably have noticed the pull of the lever when the sticking clutch event occurred was harder than normal. The Focus I drive has had similar issues with the clutch for other owners, not I ( pedal sticks to the floor and a hard pedal for the first operation after a freeway drive without using the clutch for a while) and the dealers were replacing clutches and master cylinders and slave cylinders etc only to have the condition re occur. When I investigated my car and another one both reservoirs were way over filled from the factory. They have cast into the reservoir an arrow pointing down with a line above the arrow and the word "full" so everyone fills to the "line" which is in fact over full. When you fill to the arrow tip that's the full level and leaves expansion room. I dont think there's been a single event since i mentioned this on a forum. The natural thought is to "fill to the line" which in this case is wrong. The hard pedal push after a run without clutch use is due to the fluid heating up and expanding. Its a bit like the mal adjusted brake lever freeplay issue. Is this the issue here? don't know but its an easy place to start. Ciao

-

That would be good Pete, and an image? Ciao

-

For those interested in 78 mm crank differences. On the left a Centauro and later Daytona crank. On the right a 78 mm Cali crank. I think the earlier Daytona cranks that used the standard rods also used the Cali version with the balance adjusted but as can be seen the difference between the Cali 78 mm crank and the Centi/Later Daytona cranks is a lot more than just a dynamic balance adjustment. The 78 mm Cali crank is just a heavier version at 8.3 kg compared to 7.5 kg for the Centi and later Daytona Cranks. No wonder the lighter Centi crank and single plate flywheel feels like a Ducati engine. Ciao

-

Its not overfilled is it? Ciao

-

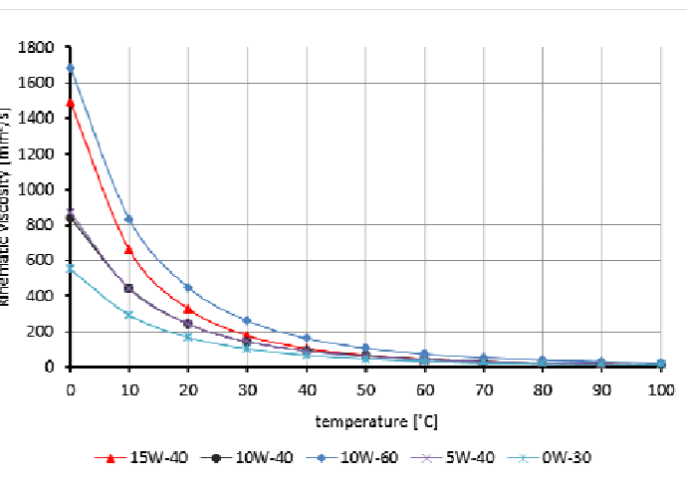

In your climate John your running oil temp even ( not traffic) in summer will probably only be around 100C maximum, probably a fair bit lower. As you can see from the graph below with regards to the change of viscosity from 80 to 100 deg C its very small. It's not a straight viscosity reduction but an exponential change so the difference between 80 and 100 isn't great. The issue you have though isn't going to be at the top end as you wont be needing max oil pressure when the oil temp is up around or over the 100 deg C point, that will be when you're in traffic and even if you did the pressure at 100C will probably now be around the 65 psi mark which is still plenty. Your concern is at the bottom end with the oil light coming on, or has been. Presently you have 32 psi idle pressure at 80 deg C and you wont have the LOP light issue any more even at 120 deg oil temp. From the graph you can get a reasonable idea. I'd estimate the top end at 120 deg C will reduce to around 55 psi and the idle will be around 15-20 psi. plenty in both cases. Of course this doesnt take into account engine clearance changes with temp so it will still be interesting to see what the actual figures are. Ciao

-

I'll get it out and post some images. This tanks paint is actually close to perfect. Certainly any minor blemishes can be addressed with a hand cut and polish of the clear coat. Looking inside the tank I dont even know if its ever had fuel in it. I bought it years ago and never used it. It will also need a pair of 30103730 vent fittings. There is a pair on ebay USA now for $15 new. Item # 324118401061 PM me and if your interested we'll work something out. I'm guessing the postage may well be around $100US as well. Merlins defect inspection......Pass Ciao

-

Yes I think this is a common issue with those tanks I think. Its Ethanol related from memory but remember it's not actually the Ethanol itself but the water it attracts. Thats what causes the leaching issue which affects the decals and finish. I have one of these tanks here which is unaffected but the paints not absolutely perfect you could have for $100US. The shipping might be the issue though. Chuck internally coated his tank quite a few years ago and I think it's still holding up. Ciao

-

For the experts: best sender locations for oil temp and pressure

Lucky Phil replied to po18guy's topic in Technical Topics

For those interested, here is the jackshaft from a Daytona/Centauro engine compared to the replacement from an MGS-01. The Centy jack shaft replaces the 2 valve engines cam shaft and is driven by the crank gear at the front which in turn drives 2 belt pullies mounted off the front of this shaft. The MGS-01 does away with the whole back end of the Jack shaft and plain bearing at the front of the cases and replaces it with a ball bearing. Smart move as it saves the friction of the jack shaft rear bearing and also replaces the front plain bearing with a low friction ball bearing. Ciao -

For the experts: best sender locations for oil temp and pressure

Lucky Phil replied to po18guy's topic in Technical Topics

No Pete the MGS is still a 78mm stroke. Like the needle bearing support at the nose of the camshafts instead of the plain bearings it's a friction elimination solution I believe.I like the later 1200/1400 chain drive arrangement better as well. Neater more compact and gives the cooling airfow a straight shot at the head. I'm not sure if the MGS used the big bolt carrillos or not but I'd be surprised if they did. It MAY also have used slightly longer rods I need to check that. The engine I'm building wont be the same sized bore as a MGS though I'm going to use 95mm pistons and probably the same length rods as I have a set of brand new H beam rods with oil squirters for a Guzzi in the std length. I'm sure the piston manufacturer can accommodate any compression height I want though so I need to look at piston to rod ratios and see if there's anything worthwhile to be gained by buying expensive longer rods. Ciao