-

Posts

5,686 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by belfastguzzi

-

Good advice, thanks.

-

Its great to be English

belfastguzzi replied to Guzzirider's topic in Special place for banter and conversation

Hmmm, sounds like the Erin rally. -

You mean, butler? I know you're not posh enough to call your serf a sommelier.

-

You're way off topic, Bendy. That thing ain't got nearly enough pointy-out cylinders for this thread.

-

The AJS, don't you think?

-

It's obese.

-

There's an idea. Must seek some out.

-

Yeh it would be a hard choice if Santa was offering something from either AJS or else Vincent / Norvin V the fabulous Nogbad will like this one must have inspired Lord Hesketh and this has a certain brutish charm

-

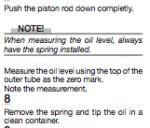

Unfortunately I didn't. From what I can make out, the older Ohlins manuals recommend springs out, while the newer method is spring in. I measured with spring out, because 1) I looked at the older manual 2) it's hard enough to see the level accurately, even with the spring out. It's more difficult to measure down the side of the spring when it's installed. When refilling I filled to 165mm (spring out). Somewhere in a manual, stock seemed to be 170mm. That can't be right, as you have measured stock gap as 141mm w/o spring (? = 85 with spring in ?). I found the volume of oil in a leg to be slightly over 500ml. When refilling to a gap of 165mm I didn't use as much as 500ml. The various figures that I have noted, from the other suspension thread in particular, don't all equate to each other properly. Could some more people post figures, to get a better picture of what the gap measurement range is? What gap(s) is used at MI (springs out)?

-

Not yet. It's on one of my many long lists. I did top-up the engine oil today though and was surprised by how much went in, so you were probably right about low level causing the oil light to come on last time.

-

Thanks. If I understand right, you answered the main query with: There is a saying in mechanical engineering circles that you can tighten to failure, but you cannot tighten a screw to fail. So if it's in place and didn't cause damage while tightening in, things will be ok, as far as the threads are concerned anyway. I'm aware of the warping danger, but tend to think that it's less consequential if the head is tight down even if not perfectly balanced, than in its prior state when it was at the original torque settings but allowing oil out somewhere. BTW, as it happens, my next car job at home is to get a broken exhaust manifold stud out of a VW Polo motor.

-

One of the Hundred Best.. Cartoons, this time.. happens to be on tv – Noggin has just come on! Olaf the Lofty made a fire machine (early Hesketh) and it ran away, over a cliff. Brill!!

-

Don't eat it all at once.

-

!!!!! I wasn't referring to Heskeths!!!!!

-

I din't know that you're evil

-

Yes. I was referring to my old thread, one of the first that I posted here, which noted the familial relationship between the two bits of machinery (in my eyes). That's my Scura! Can't find the thread, but that's the pic from it. What's happened to the Search facility anyway? It's accessed in different places, in different ways, depending upon where you are on the board. Is there still an advanced search function somewhere? Er, it's ok to love obsolete machinery, isn't it?

-

Hesketh – uncanny indeed. uncanny adjective: 'the Hesketh was uncanny' eerie, unnatural, unearthly, preternatural, supernatural, otherworldly, ghostly, mysterious, strange, unsettling, abnormal, weird, bizarre, surreal, eldritch; informal creepy, spooky, freakish, freaky.

-

Oh look. An elephant family at the National MC Museum.

-

The loosening top plate on the Quat box has been commented on before I see that the sealing fibre in mine is now well blown out and the plate sits loose with loose rivets, exhaust blowing out through it onto back tyre. Should speed-up tyre warm-up. Ho hum. What's anyone done for a longer lasting (permanent even) repair solution? The big flat top of the box makes a superb frying pan, for the continuously leaking gearbox oil. Ho hum. Still sounds great.

-

He'll be using a figure appropriate for that, which presumably is a bigger gap at that stage than the figure for when the spring is in. The manuals are a bit confusing as there doesn't seem to be one for exactly the fork model that Guzzi's (02) have and the different models' manuals give different advice. Dominant advice is that springs must be in. MG's own manual adds to the general confusion as it gives completely wrong information on where the compression and rebound adjustment is. Springs in, or springs out, can't be a crucial issue. The correct oil height / air gap for either situation would be the thing that matters. Is the revision kit just the updated Ohlins seal design? The Ohlins tech that I spoke to said that you couldn't keep up with the original seals and that the revised design has been a great improvement. However, controversy as usual: Baldini has said that in his experience the newer seals are no better. So far, my replacements are ok... so far. BTW in an older thread there was mention of the importance of using Ohlins green grease to keep the seals lubricated. Again the manuals are a bit confusing as some say green grease and others say red grease. One is older than the other, I can't remember which way round it is. But the point is --- that Ohlins race people don't use it. They take a dab of whatever they have. It's not important to use Ohlins grease.

-

Fascinating stuff alright. Back to domestic scale, Ryland's info makes me wonder again about the head bolts on the car I'm driving. It was weeping oil so I tightened the bolts. I didn't want to go through a whole head loosening and tightening procedure. I put a torque wrench on but it clicked pretty much straight away. Not sure how much I could trust the click I tightened the bolts, some of which took more than others. I was very worried about pulling the threads out of the aluminium block. Tightening by feel isn't the best thing in this application, but it did the job and the block is still clean and oil free. – How much danger is there of stripping the threads in an aluminium engine block and when, roughly, is the danger point approached? Presumably oil in the threads makes that danger more likely. – How accurately can the original bolts that are in place be torqued to a good tension, with out starting again from scratch, sequencing-up with new bolts and clean threads? Is there any point in using a torque wrench at all in a situation like this? – In the real world could the sort of uneven and possibly over-tightening that I have done be causing a problem for the longer term?

-

Thanks to Jaap whose comment about oil spills under Brit bikes made me think of this ------- Came across this very nice little piece. Similar story to the Guzzista love affair. (**One of the first pics that I posted on this board was a Seagull and V.11 together ) > The British Seagull outboard motor is no longer in production,with the last of its parts-and-products inventory having been bought out by Seagull fanatic John Williams in 1996. (The company had been producing the engines for 65 years.) Yet the motors live on, and many of them remain in service of their owners around the world. When asked about the Seagull heritage, Contributing Editor Chuck Husick poured forth with the following eulogy: "They are much too heavy, make far more noise than they should, drip enough very oily gasoline to calm an aroused sea, can be difficult to start, lack a neutral or reverse gear on all but a few of the larger models, can't be swung around to provide reverse thrust and, unless equipped with an optional and very heavy recoil starter, enable the operator to hit anyone nearby in the face with the starter cord. Still, they are loved by those who own one. "The Seagull is an excellent example of early Industrial Revolution engineering and design. There is nothing delicate about them. To most eyes, they are ugly to a fault. But they provide more low-speed thrust than motors twice their size. Put one on a soft-ended inflatable dinghy and watch it compress the aft tube as it moves the boat forward. If a mechanical problem arises, a screwdriver and a pair of pliers will be just about all you will need to fix it. The carburetor is simplicity itself and can be disassembled, cleaned and reassembled in about three minutes, and there are no gaskets to lose. Open up the powerhead and look at the safety-wired cap screws on the connecting rod end: looks like an aircraft engine. Want to check the lube in the lower unit on the 2-hp model? Why bother? There are no oil seals, and the box was filled at the factory with something that resembles warm tar. A bit of salt water likely makes it run better. "The engine uses an 18-mm sparkplug, making it easy to clean the plug with whatever size knife you may have at hand. As for plug gap … whatever looks good. The specified oil-to-fuel ratio is 1:25, or is it 25:1? Does it matter? The original fuel tanks were painted steel, guaranteed to rust through in no more than two years. (Blockage of the little fuel-filter screen hidden in the tank outlet valve kept many a Seagull from running past the first year, in any case.) A fine plastic fuel tank was offered as a replacement for the original steel, but it lacks the cachet of the dark blue paint on the original. "Let's face it. The Seagull, at least my 2-hp Seagull, is totally obsolete, far, far too heavy, makes more noise than a modern 25-hp engine, makes me want to hide from the oil-spill inspectors and, once started, can only be stopped by putting your finger over the carburetor air intake, which both stops the engine and keeps your finger from rusting. But, I love it. Where else can you operate a piece of machinery that looks like it was designed in the early 1800s and built in a blacksmith's shop? Last, but not least, it is known, at least in our family as the only outboard motor in the world with no moving parts." **Can't find the old thread now: this was one of the pics

-

General, not specifically Guzzi, but I came across this and thought it was interesting: > These studs are rated at 190,000 PSI (consider that Grade 8 is less than 150,000 PSI). Included washers are hardened, and the 12 point type nuts are of the aircraft type... .......30 cwt. engine oil, or the recommended ARP lube, part number L99 should always be used, and the different torque specifications for each type of lube followed. The tension obtained in the fastener (which is what we need) is affected by how well the lubricant being used is coated evenly on the threads. When using oil, and especially when using the ARP low friction lube, it is highly recommended that the following technique is followed: - Coat the fastener with the lubricant, and especially with the lube, try and rub it into the threads as evenly as possible. - Screw the nut down and pull up snugly with a wrench (spanner), repeat this three times. - On the third go torque to the recommended torque setting. All of the above might sound a little odd, but many carefully controlled tests have shown that this method distributes the lube evenly between the friction surfaces, so increasing the tension each time for a given torque. The difference in tensile load between step #1 and step #3 can easily be well over 1000 pounds on a 3/8" stud or bolt… very significant! Always run a tap down each threaded hole prior to installing the studs. Use a bottom tap (called a plug or #3 tap in England). Where possible we recommend using a 60 degree counter sink into the top of each stud hole. This will help stop the top threads being pulled up above the surface. We don’t recommend using Loctite type compounds on studs or bolts, but if you feel you want to, then be sure to complete the job, including final torqueing before the compound 'sets up'. Studs should not be screwed into the block very tightly, only about 4 ft lbs is all that is required (not much more than hand tight). The torque figures we recommend will give a preload equal to 75% of the yield strength of the fastener. ........like many other things in life, sometimes when you get into it a bit, you might find there is a little more involved than just "screwing it together"!

-

Hmmm... there's no rain either... could these be Japanese copies??

-

I would say, D.I.Y. Nog – delete it and re-post – EXCEPT that is one ugly bike! You can't be serious, surely? Hesketh was a Brit who did it bigger, not better (in the style dept. anyway). Too late for days of Empire: and elephant hunts. AJS is Essense of Motorbike. Hesketh is Essex Motorbike. Know what I mean? Edit: actually, I protest too much. The V1000 that you showed isn't that bad, but he did generally favour the elephantine. Know what I mean?