-

Posts

123 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Onibaka

-

Hi friends, I rarely come here lately. A couple of years ago I bought myself a KTM 1290 and I was already thinking about selling my V11, since it was standing idle in the garage, but the KTM breaks down more often than I expected and while it is being repaired I ride my trusty Guzzi. Recently the motorcycle has become difficult to start when cold even with the throttle handle. I have to crank the starter for a long time. Also, my regulator relay bracket was torn off and it flew under my wheel while driving, tearing out the front wheel fairing. So for now I ride without it and secured the regulator relay with cable ties to the oil supply hoses. Otherwise, everything is fine with me, I am alive and well, glad to see familiar nicknames here and I hope you, my dear friends, are also okay.

-

Hi all. I'll update this thread so I don't create a new one. Recently, on the go, the motorcycle began to stall and lose power, I thought it was a problem with the TPS, but then I heard how, after the engine was turned off, fuel began to drain into the tank. As I understand it, the fuel pressure regulator does not hold. I took it apart and found pieces of some kind of plastic. I have no idea what it is or how it got there. Could it have been something inside the regulator originally and it fell apart?

-

Hello! Only this season I put this mod. I am delighted! Such clear shifting! And using the quickshifter has become much more comfortable.

-

Something went wrong. Thanks po18guy for the help. Hello everyone

-

-

Yes, I put my old TPS and now the V11 works fine

-

The problem is found and resolved. Everything turned out to be very banal: the TPS sensor died. I checked all the relays, sensor resistances, ignition coils and all harness connections, grounding, fuses, and only at the end I decided to check the TPS. You may ask: "why I did not check it first"? Last year I had a very similar problem and then I ordered a new PF3C sensor. As it turned out then, it was a wire to the relay, and I left this new TPS. And I did not expect that he will serve me less than a year, I traveled on it for about 4,000 km. He returned his old PF4C sensor from Harley and everything is great again! In fact, I thought that I would sell it to hell and buy a Japanese motorcycle. He got scared and earned

-

Another problem After rain, the engine runs intermittently, as if the spark does not always fire. This already happened after the rain, but then after 10 minutes of malfunctioning the problem went away and he drove as if nothing had happened before the next rain and now the problem does not go away. The engine starts only with the gas handle open and stalls when the gas is closed (at idle). The engine itself works coughing and unevenly. Maybe there are places where moisture can get after the rain, which could lead to such consequences? I connect this problem with the rain, because it happens the second time after the motorcycle gets wet. I exchanged relays for working ones and before that I was pressing contacts. Grounding on the box is also ok. I inspected the candle high-voltage wires but did not find signs of wear. Valves have been regulated recently. There are cracks on the connecting horns from the air filter, but it seems to me that could not lead to such consequences. At the weekend I will check the readings of the sensors (TPS, temperature), the pump contacts (it is new). Maybe R.P.M. AND T.D.C. sensor? I found forum posts with a similar problem. Just until I realized how it can be checked. Glad to any advice

-

I wrote a letter to Chuck ordering one for myself Before that, I could switch up using quickshifting, briefly dropping gas at high engine speeds. Maybe it will be more convenient

-

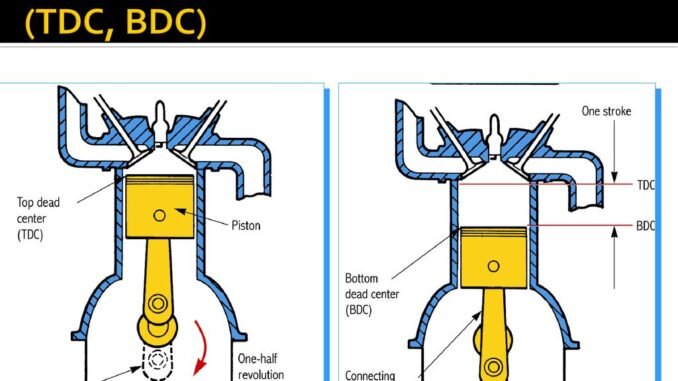

I adjusted the valve to 0.15 / 0.20. Everything seems to be fine) Maybe in vain I started a discussion here, but we talked and you know that I know what TDC is

-

I do not quite understand what you are taking off for, but probably something useful. I read a little later and can join

-

Guys, I’ve been trying to explain many times that adjusting valves for me is not a problem . I am sure that the piston is in the DTC position. I see the movement of the piston in the hole of the spark plug, I see the mark D (for the right) and S (for the left) of the cylinders. The piston during DTC is in compression. Both valves have a gap and I can adjust them. All the same, I have my Guzzi for the 8th year and I have done this procedure many times. doсc understood correctly. This is my question, I noticed that the valve clearance in the TDC position is not the largest for the entire crankshaft revolution cycle. That is, if the intake valve clearance in the TDC position is 0.15 mm, then with further rotation of the flywheel, when the piston leaves the TDC and the exhaust valve opens (exhaust stroke from the combustion chamber), the intake valve clearance increases to 0.20 mm. This is also true for the exhaust valve. That is, on the injection cycle (when the injection valve is open), the clearance of the exhaust valve is greater than in the TDC position I hope you understand me. I am sure that I am not confusing TDC. I just accidentally decided to measure the gaps in other positions of the piston (not in the TDC) and they turned out to be larger. Maybe it's me having some problems with the camshaft. Or maybe this is normal? I just want to understand this issue. Yes, I decided that there should be something themed

-

Yes ... I consider this as one option. Only, logically, the gaps in the TDC should have changed, but they remained at the level (it seems). Okay, set it up again and watch. Maybe the next time you adjust the valves, pay attention to this

-

Yes, I know about this fact. Adjusting the valves is not a problem for me. Oh... you don’t seem to understand what I was trying to explain Thanks, it will be interesting to try it

-

And the fact that the valve clearance may increase when the piston leaves the TDC is wrong? Or maybe it's okay and I'm worried for nothing

-

It seems to me that you did not quite understand the problem I described. I am sure that I put the valve in TDC, I took out the candles and rotate the generator nut to the D and S marks and to the desired engine cycle. I have adjusted valve clearances many times and this procedure does not cause me any difficulties. An initial reduction in clearance was expected, as I bored the valve and valve seats and changed the valve spring gaskets. All this sat down and finally worked out and the valve clearance decreased. After that I re-clamped the cylinder head (gaskets changed) and adjusted the valve clearances to 0.15 / 0.20. That was about a month ago The other day, I heard the knock of valves and decided to re-check the clearance. In the TDC position, the clearance did not change, it remained ~ 0.15 / 0.20, but if you rotate the crankshaft further, at some points (after exiting the TDC) the intake and exhaust clearance may increase by more than 0.05mm. For the video, I adjusted the valve to 0.10 / 0.15 in the tdc position (video 1), and you can see: Video 2 - 0.15 intake clearance, after crankshaft rotation (in tdc - 0.10) Video 3 - 0.20 exhaust clearance, after crankshaft rotation again (in tdc - 0.15) I think this is not very similar to the wear of the crankshaft. Perhaps it looks like he's bent, but I don't know ... I want to watch the gap situation a little more. Only I would advise in what position to adjust the valve. In TDC or each valve individually at the time of maximum clearance (this will reduce its clearance in the TDC position)

-

But I don’t think I have this case. In the TDC position, the gaps did not change much after tuning.

-

Mark "D" for the right cylinder and in the spark plug hole I see that the piston is at the top. In addition, this is the only location of the flywheel when both valves have clearance. The other two videos show that the opposite valve is pinched

-

I have a question on setting the valve clearance. This winter, I took off the heads of the cylinders to replace the o-rings that flowed. After assembly, I adjusted the valves, and after some mileage I checked them, they were tightly clamped, I adjusted the gaps in the T.D.C position again and later I was confused by the strong knock of the valves. I started checking gaps again and found that in the T.D.C position the gaps were not the biggest. When the crankshaft rotates, when the exhaust valve opens, the intake valve clearance increases (relative to T.D.C), and when the intake valve is open, the clearance of the exhaust valve increases (relative to T.D.C). Thus, at different positions of the flywheel, the valve clearances increase by approximately ~ 0.05-0.07mm relative to their adjustment in the position of T.D.C. It looks very strange, and I thought that there should be maximum gaps in T.D.C. If this is not a normal situation, then I do not know how to regulate the valve. Should the gaps be set according to TDC or according to the maximum clearance of each valve? The issue is both with the right and left cylinder. I will attach a video where I try to display the situation (usually I set the gaps at 0.15 / 0.20, but on the video they are set to 0.10 / 0.15) T.D.C 0.10 / 0.15: exhaust pinched - intake clearance 0.15 (~+0.05) exhaust pinched - exhaust clearance 0.20 (~+0.05)

-

So , you don't like the social distancing ?

Onibaka replied to gstallons's topic in Special place for banter and conversation

I am always near. I read the technical branch) Tomorrow I will open the motorcycle season!

.thumb.jpg.957a0814c9666a69e7425b4a495b055f.jpg)