-

Posts

4,002 -

Joined

-

Last visited

-

Days Won

247

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Scud

-

ANSWERED I give up, where are the fork mod threads?

Scud replied to Craig's topic in Technical Topics

Perhaps you've been eating the wrong king of cactus. Check with Chamberlin. I think he might know a reasonable-cost way to get into a set of Öhlins that are cross-compatible with another bike. I don't recall the details. -

No question is dumb so here goes: Anybody ever paint their forks?

Scud replied to Goosed Again's topic in 24/7 V11

So your bike is like this one in the gallery? So much potential for darkening... Yep, just like that but the previous owner stripped the pork chops so I'll need to repaint them as well. Sounds like you might be embarking on a project... Maybe you should start a project thread about your bike (and post some pics). Is it new to you? FWIW - I got a lot of great advice when I did a project thread for my bike. I ended up doing a lot of important things that I would not have thought to do on my own. Staying in the dialogue on the forum also pushed me to get everything done faster than I probably would have otherwise. Now I am "chuffed to bits" (to borrow a British expression) with my bike, I know my way around it, and I have a good sense of things to watch out for. -

Looks like a useful accessory. I just ordered one. Thanks.

- 61 replies

-

- TPS

- TPS connector

-

(and 2 more)

Tagged with:

-

I just threw out the question to get us started. My question has been answered beyond my expectations, and I don't feel any need to make rules about where it goes from here. Some stories about actually using what you carry to fix it and make it home sounds like fun though. Perhaps the stories will jog someone's memory about something else to add to their kit. The idea for this thread came to me for two reasons: I carry a lot on my dirt bike - in fact, I try to do all my at-home maintenance with only the tools I carry. I haven't had to spend the night in the woods or desert yet - but I also carry stuff in case I have to - food, water, plastic poncho, mylar emergency blanket, lighter, etc.. I had to fix the Scura on the road within a few days of getting it. I wrote about my Scura misadventure in another thread already, but here's the summary: The bike was idling higher and higher at each stop light - and it got up to about 3,000 or 4,000 RPM. So I shut it off, twisted the throttle wide open and released it several times. Then started the bike again. It instantly revved to redline. Hit the kill switch and pushed it out of traffic. The problem turned out to be that the grease on the throttle linkage had hardened (the bike was in storage 12 years and this was within the first few miles of putting it back on the road). I used the stock tool kit to disconnect some linkage and isolate the problem - which was on the left side. Luckily, this was next to an auto parts store, so I bought some penetrating lube, worked it in and rode it home (instead of needing to load the bike in a truck). Not a terribly interesting story or complicated repair, but maybe somebody's now thinking "When's the last time I lubed my throttle linkage?" or "Should I throw a little lube in my kit?" or "Can I fit a plastic-bag poncho under the seat?"

-

That poetic description also works for my use of the Cycle Gear stand. With the sidestand down, I get on the right side, pull her up and close up to me with my right arm and use my left arm to prepare to sweep her off her feet with the swingarm stand. I had help the first few times, but I can do it alone now. The lifting surfaces of the CG stand are two square rubber blocks that rotate. I added some leftover surfboard traction pad foam to the brackets to prevent damage while lifting. When it's up, I secure it with two clamps, as shown in the picture. Again - probably not the "best" option, but it works and it doesn't slide off. I have left the bike on the swingarm stand like this for well over a week (while the sidestand was getting powder-coated).

-

Chin spoiler is soooooo easy, all pre-drilled and easy to get to... only two sizes of allen wrenches needed... possibly some sanding required if it buzzes like mine did. So if Chamberlin is putting on a chin spoiler and Craig is putting on a rear inner fender... Craig will be doing more installation and Chamberlin, perhaps, more partying. More info about ordering in V11 Chin Spoiler Search

-

No question is dumb so here goes: Anybody ever paint their forks?

Scud replied to Goosed Again's topic in 24/7 V11

Wraps are fairly thick 0.003 or so and soft. That would increase the diameter of the fork 0.006". You would have to avoid wrapping where the triple clamps mate to the fork. I can imagine lots of badness trying to clamp over the vinyl. I agree that a soft layer between the fork and triple clamp sounds like a bad idea - they might not even fit with the wrap on them. I assumed the wrap would be done with the forks still on the bike - and trimmed at the triple clamps. That would require wrapping four sections. You might have to remove the wrap from the sections between the triple clamps before removing the forks for service. Thinking more about the process... it seems like it would be difficult to join the edges of the plastic wrap, because you'd have to go all the way around the fork tube and try not to leave a gap or get a raised seam. Lines up the back look good on some kinds of legs, but maybe not on motorcycle fork legs. -

No question is dumb so here goes: Anybody ever paint their forks?

Scud replied to Goosed Again's topic in 24/7 V11

So your bike is like this one in the gallery? So much potential for darkening... -

No question is dumb so here goes: Anybody ever paint their forks?

Scud replied to Goosed Again's topic in 24/7 V11

Black is good. Hangers By rear hangers, I assume you mean the parts that go from tail frame to passenger peg and exhaust hangers? If so, I recently had mine powder-coated flat black and am pleased with the result. I had a bunch of parts done at the same time: posted in #126 of Brand New Scura. Also see warnings there regarding where to mask the brackets and passenger pegs. Forks Think cautiously about powder-coating the fork tubes; it will slightly increase their diameter, which could make it hard to fit back in the triple clamps. I thought about black fork bottoms too - but powder-coating them required too much disassembly of valves, adjusters, seals, etc. If, in future, I do get the urge to black out the fork bottoms, I would just use spray enamel on the complete parts, then some truck bed liner on the leading edges - or powder-coat them if/when they need to be totally rebuilt. Wraps are cheap and can be peeled off - and installed again. Seems like that would be worth an experiment... -

That's right, you have to take off the inner rear fender so you don't break the plastic with the weight of the bike. Some aftermarket inner fenders mount differently though - and don't have to be removed. Maybe we're not talking about the same thing, but I'll try to clarify. The stock plastic inner fender wraps the swingarm and does not bear any weight. I assumed that the part of the fender that wraps underneath the swingarm would break if it was still on when using a swingarm lift. It's easy to remove anyway - so not really a significant factor in deciding what lift to buy. Here's a pic from the workshop manual showing a swingarm lift in use - with the inner fender removed. It's interesting that MG chose not to recommend the factory stand for that. Seems to me that we need a few different ways to raise our bikes, depending on the work to be performed. Next, I am going to try some anti-gravity powder.

-

That's right, you have to take off the inner rear fender so you don't break the plastic with the weight of the bike. Some aftermarket inner fenders mount differently though - and don't have to be removed. On the Cycle Gear stand vs. the Harbor Freight one: CG has a handle/lever (HF doesn't - but the U appears to be bigger for leverage) CG has square rubber blocks that lift the swingarm and rotate when you lift the bike - I only added padding to an outside lip. On the HF version, the part that lifts the swingarm is shaped sort of like this: ] CG seems a bit sturdier (and costs a bit more) - but both do the job Anyway - the CG one is working well for me (especially because I replaced the stock inner fender). I'll stick with it for a while, possibly till I need to remove the swingarm, which, obviously, is a task the swingarm stand cannot do.

-

I also wasn't sure how to interpret the stroke. I figured maybe it's one of those words that gets used differently sometimes - like torch = flashlight. I'd never use a torch on my motorcycle - it could catch fire.... And when you do solve the case of the disappearing clutch fluid, I'll be curious to hear the solution. Wishing you the best in your recovery - and in the home brewing.

-

When you say you inspected the slave, I assume you completely removed the slave from the case so you could inspect the inside. Is that correct? If it's not leaking on the outside (eliminated the impossible), then it must be leaking on the inside (however improbable, must be true). If it is leaking internally, the fluid would go into the case, and this would be very hard to see - even with the entire slave cylinder removed (per illustration in post #4). Some further investigation ideas: The fluid is thin and almost clear. Maybe you could try dabbing some on a screwdriver to see how it looks on a part. A small flashlight might then help to search the bike again - it focuses your attention and the light will reflect differently off wet and dry surfaces. Docc suggested I used foot powder to investigate an oil leak on my bike. Maybe that would work for this puzzle too. You could try coating the master, line, and slave with powder and just squeeze the clutch several times - see if anything gets gooey. If not, go for a short ride and look again. The only differences between the stationary test and the riding test will be wind and heat. I don't see how wind would make a difference, so if it does not leak while cold and stationary, but does leak while riding, I'd focus on the parts that get hottest - the slave cylinder and any sections of the line that get close to hot parts. Until it's solved, stash a little bottle of fluid under the seat. If you keep riding it and the leak gets worse, it will become easier to solve.

-

A tube of grease.

-

Actually I went to Cycle Gear and took it out to the bike and couldn't make it fit. So I'd like to see what you did to it. Sorry, no pics possible right now. I'm away from home - giving the Husky a mud-bath. So here's a mental picture instead - the stand has a big U shape. When the bike is up on the stand, the U lays flat on the ground. Two uprights at the top of the U have brackets that are the lifting surfaces for the swingarm. As you noted, the lifting surface do not fit - even with the brackets adjusted to maximum width. Therefore, I reversed a pipe clamp to make it a spreader instead of a compressor. Then I put it in the U and spread it open a bit. Looks like Gottagetone bent it by hand - impressive. BTW - I also put some foam pad on the brackets to reduce the risk of scratching anything. BTW #2 - some people have written about the tendency of the bike to slide forward on this type of stand. As a safety precaution, I used some small rubber-tipped clamps to squeeze the swingarm to the lifting bracket. So that's what I've done. But it's not my recommendation. From what I can tell, the factory stand or the Becker stand are the best investment. But even with those stands, if you want to remove the pork chops, it appears that you need something else.

-

I got a Trackside brand swingarm stand from Cycle Gear (on sale too.) I also had to "manipulate" mine. I did so by using a pipe clamp to spread out the U-shape at the bottom, because it was a bit too narrow for the V11 swingarm. It works fine for leveling the bike for service and removing the rear wheel. I also have a car floor jack that (with some boards to spread out the weight under the oil pan) can raise the front wheel off the ground when the bike is on the rear stand. I rigged up other things (like support from above per earlier photo to remove the lower shock bolt) and used a bottle jack (and more wood) at the exhaust hanger (drilled hole in wood as relief for exhaust hanger bolt) to lift the bike off the rear stand so I could measure suspension sag (1 stand and 2 jacks used for this procedure). After all that, the shop stand looks like the smart way to go - especially if you plan on keeping the bike for a while.

-

I had a Ducati Sport 1000 for a while and almost put one of the Fleda units on. They do look cool. The downside to fender elimination or reduction, as Docc noted, is road spray - and not just onto people following you. A short fender - or having no fender at all - can spray the rider. I try to be a fair weather rider, but I just can't do it - I tend to find wet or muddy areas, so for me, keeping most of the fender makes sense. After trimming mine, I do get a little spray on the top of the taillight and on top of the tail - but hardly any on the seat cowl, and none on me. I thought the stock taillight was sort of ugly too, but I like it now that I darkened everything around it. I like being visible, especially at night - and size does matter, not just brightness. FWIW, this was my approach to "tail-tidy": Removed all the tail parts and related electrics (which was more involved than I expected). Cut fender behind license plate - I used a fine tooth blade on a jigsaw. I didn't get it perfectly straight so then I used hand files to get the shape I wanted. Then sandpaper and steel wool to polish the cut end till the finish was pretty close to the other edges. Painted the chrome taillight base satin black. This, IMO, actually made the taillight look smaller. Obviously, don't paint the part by the bulb - it's chrome to make the taillight appear as bright as possible. Spray tinted the turn indicator lenses. Painted all the screw heads. Added some black reflective tape to the license plate light. Note - I did not tint the taillight. That's an option for some, but I didn't want to decrease the brightness of the taillight by even 5%. You know what's really ugly? The white California license plate. I hope I get my black plate soon.

-

I took off the snorkels. It produces a little more intake noise, which I like. I've seen a few other threads about tail sections - some really cool ones. I just sawed mine off behind the license plate, painted the chrome taillight base black, and tinted the indicator lenses. That made it stealthy enough for me with minimal expense - and kept all the lights so the cars can see me at night.

-

Rear wheel removed, Guzzi on stand: many of us do not need to remove the wheel as stated before, "on stand" is enough. Here's a pic of the grease nipple. Holy Cow--that thing is BARELY visible... And we're supposed to get a grease gun fitting on that?? Another task to add to my list for this weekend... I think this is some kind of V11 Sport New Owner Initiation Rite. It sure baffled me at first. Do the long time members sort of enjoy watching all us newbies go through our trials?

-

This low-miles 2002 Champagne LeMans is still for sale in Los Angeles. Owner is now asking $4,000. http://losangeles.craigslist.org/wst/mcy/4888059805.html

-

No doubt the Ghezzi Brian hugger is far more difficult to install than every other option that's been offered here. Cost and positioning, I guess, are matters of preference. It was part of a package deal for me - so price was OK for me at that time. When I first received it, I thought something was wrong with it. The forward-facing edge is not square and one side is more curved than the other (is that what you mean by the "dent"?). I thought it was deformed and I almost returned it. Then, when I started to look more carefully at how it fit, I noticed that the "crooked" forward edge was custom fitted to match the angle of the swing arm. It was very challenging to get the holes in the right spot. I think some mounting instructions, along with pre-drilling the holes or providing a paper template for the holes would be a good addition to this product. As for the mounting. I did have to bend the bracket a little bit. Since it is mounted in only one place (by the lower shock mount) it is not as stable as other designs that mount at the lower part of the swingarm - using the holes for the stock hugger. The fender is sort of springy - if you press it down and release it will bounce a bit. We'll see if it holds up - but it still looks in great shape after about 2,000 miles with it on. Maybe I am crazy, but even after all that pain in the a$$, I still like it. I enjoy the look of it because it seems to float over the wheel and leaves the swingarm 100% visible. I don't notice the irregularities in it's shape now that it's on the bike.

-

Rhino, it looks like it might be just us. I sent you a PM.

-

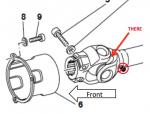

Hugger - I like the Ghezzi Brian one. There are other, far easier to install, options. But IMO, the Ghezzi Brian unit is the best design. And you'll get some real quality time with your bike - none of this bolt-on-quick-and-easy business... Have you found the front U-joint? You're looking for a grease fitting in the center of the U-joint, not on the driveshaft. Try this: Push the bike until the C-shape on the front of the driveshaft is parallel to the ground. Then look/feel into the C-shape, where the U-joint is a + shape that connects to another C on the output shaft. If there is no nipple there, push the bike again so the shaft rotates 180 degrees and check the other side. Look closely at the previous pictures in this thread. And here's I diagram from the parts manual. I put a red arrow pointing to about where the fitting should be. The diagram also shows a fitting on the shaft, which is to lube the splines, not the U-joint. On my bike that fitting is at the back, not the front. Your next post should be "success." FWIW: I have a couple dental mirrors in my tool box that come in handy at times like this.

-

Good redirect. +1 on de-burring. My Roper plate is sitting here on my desk, awaiting my next oil change. There are only two rough spots on the edges - the start/stop points of two interior cut-outs (no problems on the round holes). But otherwise, as Craig noted, all interior and exterior edges are clean and straight. The burrs are probably not even a problem, but a 5 minute file job and a quick clean up gives peace of mind - I'll probably hit all the edges with some steel wool too - just in case.

-

It's accessible, as Camn's picture shows, without removing anything - so long as you have the shortest possible grease-gun fitting on a small 90-degree elbow. See also post #30 in this thread for a view from further away, but from the same angle. Camn must have set a small camera right on the driveshaft. Post #25 has a picture from the other side - looking back toward the driveshaft from the seat lock. The procedure is sort of like an unpleasant exam. It's quick once you get used to it, you only need to do it once a year, but at least you get to wear the gloves. Sadly, there is but one V11 in my garage, so I can't make any comparisons. However, the idea that a different shock could cause a difference in clearance doesn't make sense to me, because the front grease fitting is so close to the pivot point of the swing arm. However, some of the castings are irregular (as described in post #26), which would make it hard to get a grease gun connected, even if access to it was not obstructed. From what I can see, a lot of people have bent the grease gun or modified it with angle fittings, and have been able to get it to fit without removing any parts from the bike. But apparently the challenge remains for access to the 2000, short-frame V11s.